Finned copper tube gas boilers & water heaters – Boiler Manual

22

ELECTRICAL WIRING

Electrical Power Connections

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation! Verify proper operation after

servicing.

Au moment de l'entretien des commandes, étiquetez

tous les fils avant de les débrancher. Des erreurs de

câblage peuvent entraîner un fonctionnement

inadéquat et dangereux. S'assurer que l'appareil

fonctionne adéquatement une fois l'entretirn terminé.

The electrical connections to this boiler/water heater must be made

in accordance with all applicable local codes and the latest revision

of the National Electrical Code, ANSI/NFPA-70. Installation should

also conform with CSA C22.1 Canadian Electrical Code Part I if

installed in Canada.

Install a separate 120 volt 15 or 20 amp circuit breaker for the

boiler/water heater and pump, see Table 12. A properly rated shut-

off switch should be located at the boiler/water heater. The boiler/

water heater must be grounded in accordance with the authority

having jurisdiction, or if none, the latest revision of the National

Electrical Code, ANSI/NFPA-70.

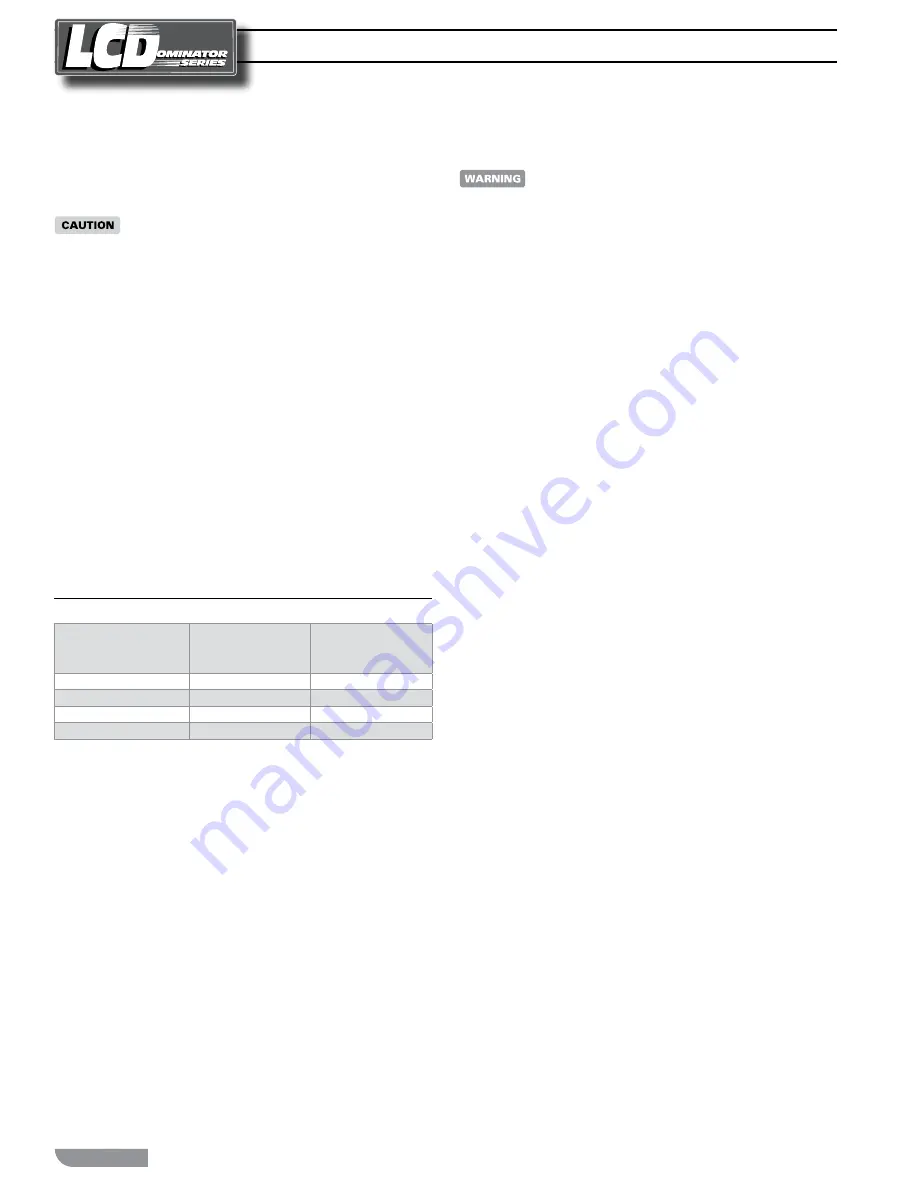

Table 12 LCD electrical requirements

Recommended

LCD

Circuit Breaker

*Running

Model

(Amps)

Amps

400 - 600

15

3.9

750

15

6.0

1050 - 1970

20

11.4

2300

20

14.4

*Use separate circuit breaker that is properly sized for pump and

pump contactor.

Line voltage field wiring of any controls or other devices must

conform to the temperature limitation of type T wire at

95°f

,

35°C

above room temperature. Use copper conductors with a minimum

size of #14 awg. Use appropriate wiring materials for units installed

outdoors. The wire size must be compatible with the total amp

draw of the circuit.

Refer to the wiring diagram supplied with the boiler/water heater

for proper wiring connections.

GENERAL OPERATION

Before proceeding read and fully understand the

instructions contained in this manual. Do not attempt

to operate this boiler/water heater if it has not been

installed in accordance with the guidelines set forth

in this manual. Failure to comply with this warning

can result in extensive property damage, severe personal

injury or death!

Should overheating occur or the gas supply fail to shut off, turn off

the manual gas control valve to the appliance. Do not interrupt

water flow through the boiler/water heater.

En cas de surchauffe ou si l'alimentation en gaz ne s'arrête pas, fermez

manuellement le robinet d'arrêt de l'admission de gaz.

Hydronic Heating Boilers

Open the make-up water valve and slowly fill the boiler and all

of the radiation with water. Ensure that all bleed and drain valves

are closed.

Adjust the make-up water pressure regulator so a minimum

12 psig

,

83 kPa

system pressure is maintained at the highest point in the

system piping. If a make-up water pump is used adjust it to maintain

a minimum

12 psig

,

83 kPa

system pressure.

Open the system bleed and drain valves one at a time to purge the

air trapped in the heating system piping.

With the boiler off, run the system pump for at least 30 minutes

and bleed the system piping using the bleed valves. If strainers are

used in the system piping, the make-up water valve should be closed

and the strainers checked and cleaned.

The system expansion tank should be checked to ensure that the

correct water level in the tank is maintained. The tank should be

less than half full of water with the system full and adjusted to the

correct operating pressure.

Start the boiler as described in the “OPERATING INSTRUCTIONS”.

Run the boiler for at least an hour. The system pump(s) and all

radiation units must be operated during this time. Ensure that the

make-up water valve is open.

Shut the boiler off and open the bleed valves to purge the air trapped

in the heating system piping. Close the make-up water valve and

check and clean the strainers and make-up water pressure reducing

valve.

Open the make-up water valve and adjust the system pressure if

necessary. The system should be checked and bled after three days

of operation.