32

MORE PAD INDOOR

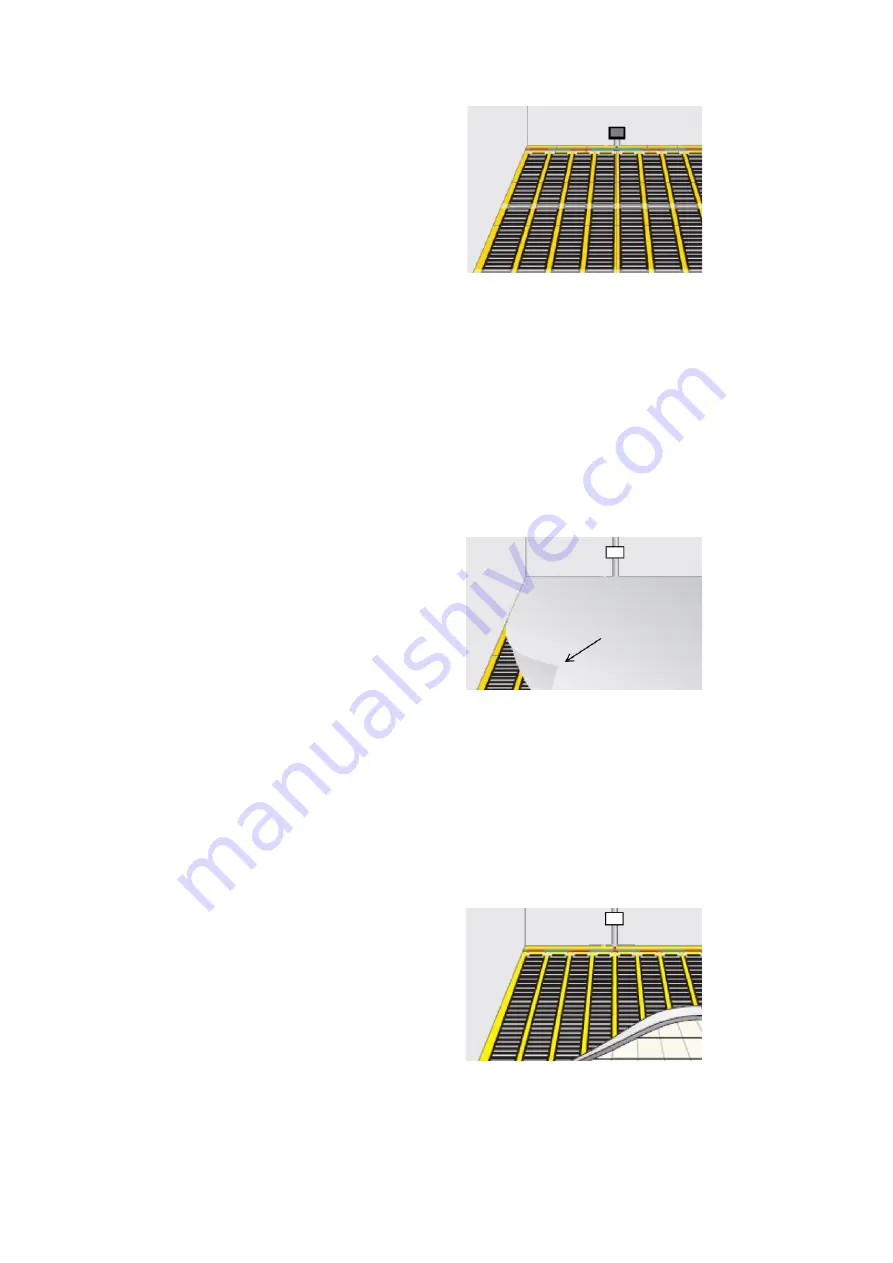

Valid for floor ONLY

The protective sheet is to be laid over the entire floor

surface, when the floor installation involves aggres-

sive cements and adhesives and/or when the laying

centre distance exceeds 150 mm in order to favour

the uniformity of the surface temperature. Along the

joint lines of the sheet, overlap at least 5 cm.

Use tape (packing tape or similar) to seal the edges

of the protective sheet, preventing mortar or glue

from penetrating underneath.

Valid for floor ONLY

It is always advisable to use a self-levelling water-

based cement screed, with a minimum thickness

of 2 cm, suitable for radiant floor systems. The

self-levelling agent must be used to eliminate any

irregularities caused by the wiring, as well as to

prevent the joints from sagging.

For the installation steps and instructions, follow the

guidelines given by the manufacturer of the screed

and the installer of the surface finish; the thickness

of the self-levelling agent will depend on the type

and size of the finish.

Wait for the self-levelling agent to dry completely to

avoid abnormal shrinkage and cracking, then switch

the system on again in the test cycle for at least 24

hours.

Valid for floor, wall or ceiling

Fasten the strings with metal staples on both sides

and at each metre, taking care to lap only the

outside of the polymer by 2/3 mm, without touching

the braids of the electrical struts.

Alternatively, use plastic nails or paper tape about 5

cm long. The only purpose of fixing is to prevent the

mat from shifting during the subsequent finishing

stages

Another alternative to staples and nails to

temporarily secure mats to the substrate, is solvent-

free reinforced double-sided tape, such as MAPEI

Mapecontact, 240 mm wide.