P. 34

MAIntenAnCe, CAre And rePAIr

15.

storage and transportation

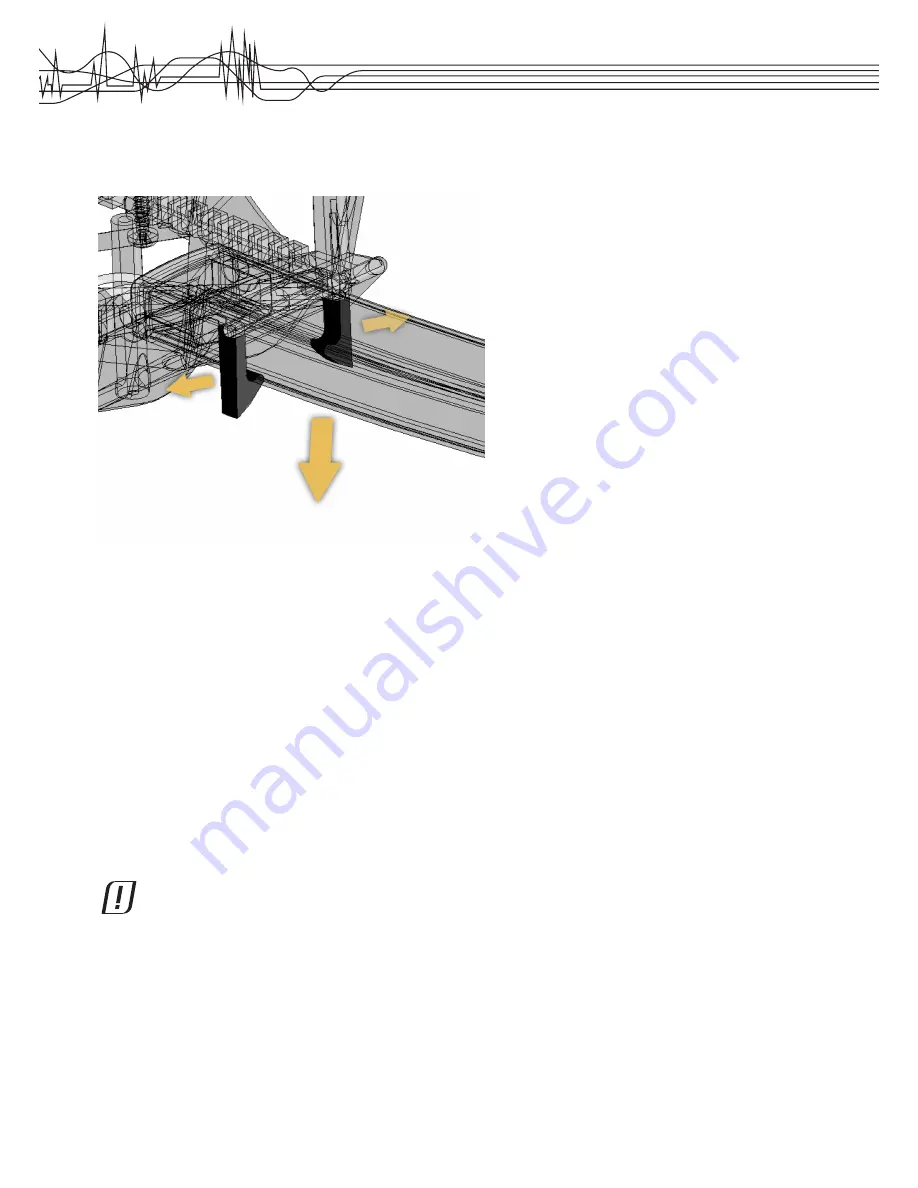

Remove the

magic.tapes.for.the.stabilizer.and.lower.the.aluminium.profile.for.storage.and.transportation.

regular cleaning

The.RC.EYE.650.is.a.very.simple.but.nonetheless.well-designed.flying.device..There.are.no.mechanical.parts.that.need.to.be.lubricated.or.

require.special.maintenance..However,.after.each.flight.operation.you.should.clean.the.RC.EYE.650.of.possible.dirt.(grass.blades,.dust.etc.).

For cleaning, use a dry or slightly damp cloth and avoid contact between water and the electronics, rechargeable battery and motors.

Do.not.fly.without.covering.the.electronics..Ensure.that.no.moisture.enters.the.inner.central.piece.(e.g..wet.grass.blades.etc.).Never.fly.when.

it is raining!

replacing the propellers

If.a.propeller.is.damaged.in.a.crash.or.other.action,.replace.it.immediately..This.also.applies.if.there.are.any.fine.tears.or.grazing.in.the.

propeller. Due to the high speed, material parts could come loose if the propellers are damaged and this could lead to damage to or

endangerment of the environment.

To change a propeller, remove the spinner and the wave washers and the faulty propeller. Carry out the mounting of the new propeller as

described in the chapter “Assembly > Assembly of the propellers“.

observe the rotating direction of the respective motor and choose the correct propellers. If they are incorrectly chosen,

the model will not be able to fly and will act in an erratic way when next started! Loss of guarantee/warranty!

replacing a motor

If a motor is defective (overheating, electrical fault or bearing failure), this must be replaced. For this purpose, carry out the following steps

as.specified:

Remove the spinner, wave washer and propeller from the faulty motor.

1.

Remove the canopy.

2.

Remove the stabilizer and the top body frame by loosening the screws. Now you have free access to the motor driver board. Detach the

3.

bullet connector from the faulty motor.

Summary of Contents for 88001RC

Page 1: ...Operating instructions 09 11 No 88001RC The picture is for reference only...

Page 38: ...P 38...

Page 39: ...P 39...