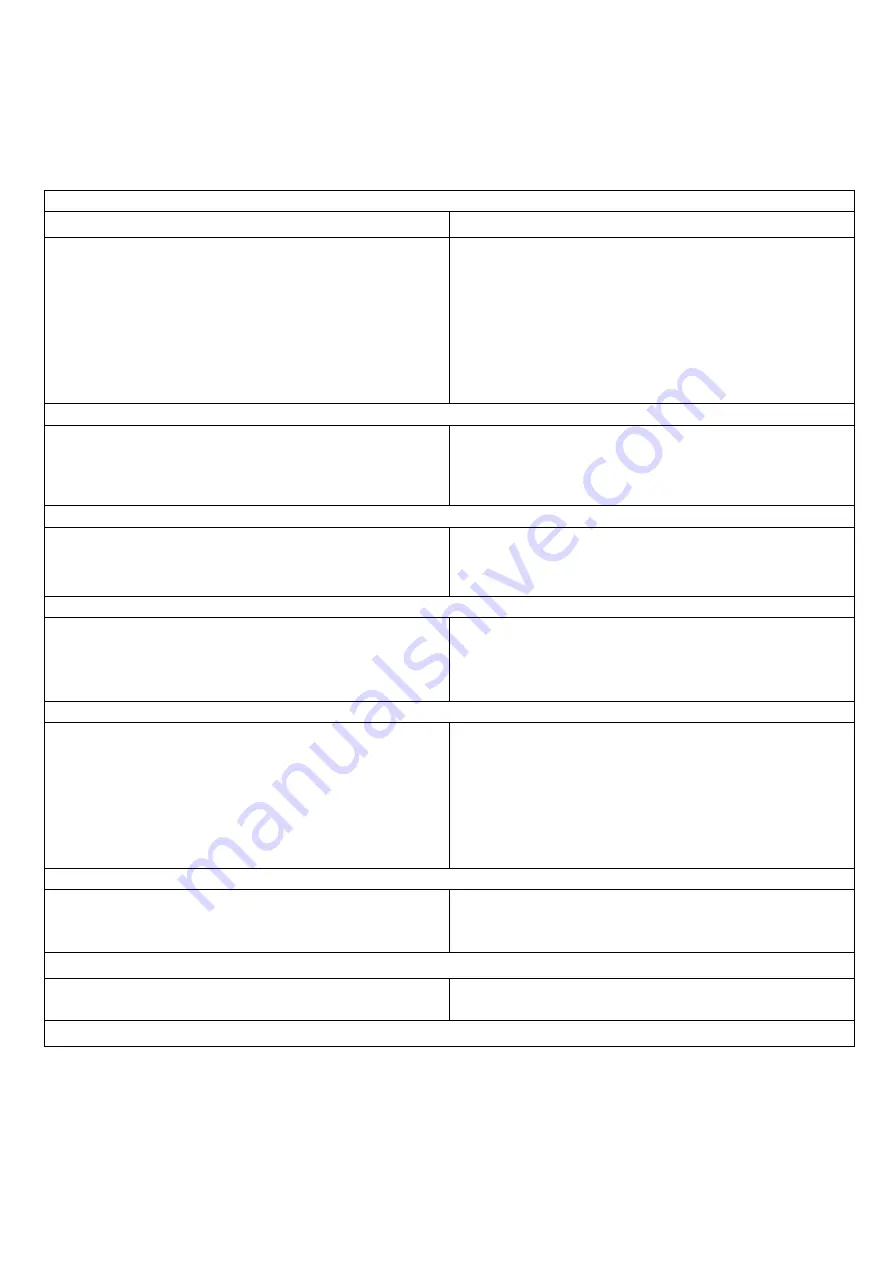

Trouble shooting

NEEDLE THREAD BREAKS

CAUSE REMEDY

Needle not properly threaded

Thread tension too tight

Something wrong with the needle

Thread is too heavy for needle

Thread check spring is broken

Needle not properly inserted

Needle plate, shuttle or sewing foot damaged

Thread properly

Loosen tension

Replace needle

Change

Have a new spring fitted

Insert needle properly

Replace

BOBBIN THREAD BREAKS

Bobbin thread entangled because of incorrectly wound

bobbin

Bobbin thread not under tension spring on bobbin case

Wind bobbin correctly

Thread bobbin correctly

STITCHES ARE LEFT OUT

Needle not properly fitted on needle bar

Needle bent or blunt

Needle worn

Fit needle properly

Replace

Replace

NEEDLE BREAKS

Needle bent

Needle not properly fitted

Fabric to heavy or to hard

You are pulling on the fabric

Replace

Fit needle properly

Use needle of correct size

Do not pull

THREAD FORMS LOOPS

Thread tension not properly regulated

Needle thread properly threaded and/or bobbin thread

not properly wound

Thread size not suited to fabric

Thread check spring not working properly

Read instructions for regulating needle and bobbin

thread tension

Thread machine properly and/or wind bobbin thread

correctly

Control size of needle and thread

Have spring replaced

SHRINKING OR PUCKERING OF SEAM

Tension too tight

Sewing foot pressure too strong

Read instructions for regulating needle – and bobbin

thread tensions

Read instructions for regulating sewing foot pressure

IRREGULAR STITCHES

Needle and bobbin threads of poor quality

Bobbin thread unevenly wound

Use top quality threads

Re-wind bobbin

MACHINE DOES NOT RUN FREELY AND MAKES A NOISE