8375 Series Troubleshooting Guide

Problem

Solution

Insert supplied Allen wrench into mounting bolt holes in the bottom of the

lock housing and turn (See Fig. 1).

- Check power supply. DC power should be slightly over the voltage

specifications outlined on the packaging. EG: for 12VDC operation supply

should be set at 12VDC-13VDC.

- Check connections at power supply, connected releasing devices

and lock terminals.

- Check that voltage selection jumpers are correctly set

- Check that connections from lock circuit board to magnet core have not

been broken or loosened during installation.

Check to see that armature plate is correctly aligned with the electromagnetic

lock. If there is improper alignment, make a 1/4” turn of the armature plate

mounting bolt and check for alignment.

CAUTION:

The armature plate must

remain affixed securely to the door or serious bodily injury or property damage

may occur. Bolt should be tight enough to hold the armature plate to the door

while still allowing for alignment with the electromagnetic lock.

This generally indicates that the lock is either operating on AC voltage or

there is some AC voltage present in the DC supply. A properly filtered and

regulated DC power supply is required to achieve optimal operation from

the lock.

- Ensure that switching devices are interrupting the DC power and not the

AC power supply voltage

- Ensure rubber washer on armature plate mounting bolt has not been

removed or damaged

- Check that switching device interrupts the positive wire and

not the negative wire (see Fig.3)

- Remove any Diodes or other suppression devices that may be installed

While some heat rise is normal for the 8375, excessive heat generally

indicates that the voltage selection jumpers are incorrectly set.

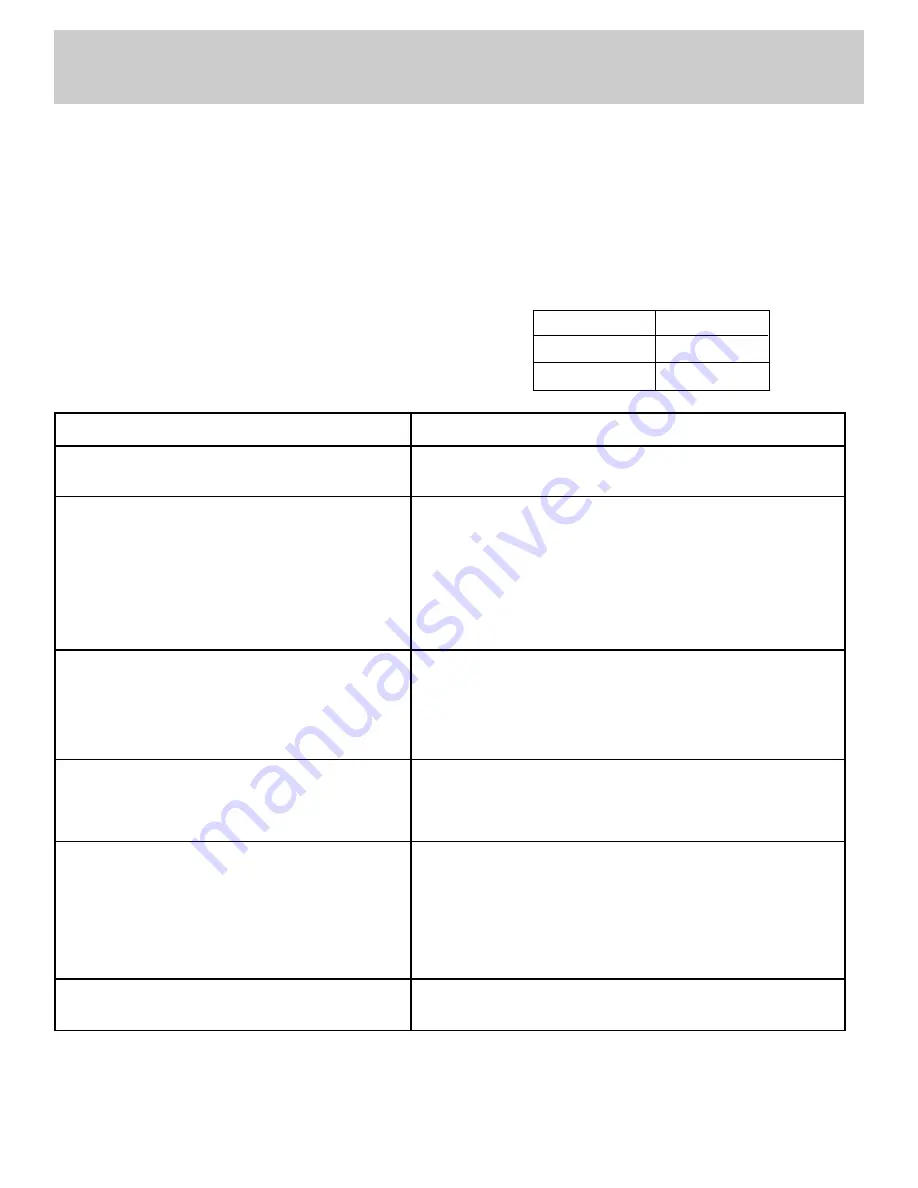

Cannot remove the lock mounting plate from top of

magnet for installation.

Lock is installed but has no holding force at all.

Lock has enough holding force to lightly hold a

screwdriver or set of pliers but door will not lock.

Lock is operating and locking but the armature plate is

“humming” against the surface of the lock.

Lock in not releasing immediately upon removal of power.

Lock surface is very warm to the touch.

8375 Installation Instructions

(Continued)

Specifications

Mechanical:

8375 Lock Dimensions

(Including 1/8" (3.2mm) mounting bracket):

13/16"D x 1-1/2"W x 6-17/32"L

(21mm x 38mm x 166mm)

Electrical:

Voltage:

12VDC or 24 VDC

(Selected by choosing appropriate voltage selection jumpers)

Current:

0.36A @ 12VDC

0.18A @ 24VDC

Environmental:

Not for use in outdoor environments.

Circuit board operating temperature:

14 to 140° F (-10 to 60° C )

NOTE: Specifications are subject to change without notice.

Voltage

Current

12VDC

0.36A

24VDC

0.18A

8375 Current Requirements

3