Product Accessories

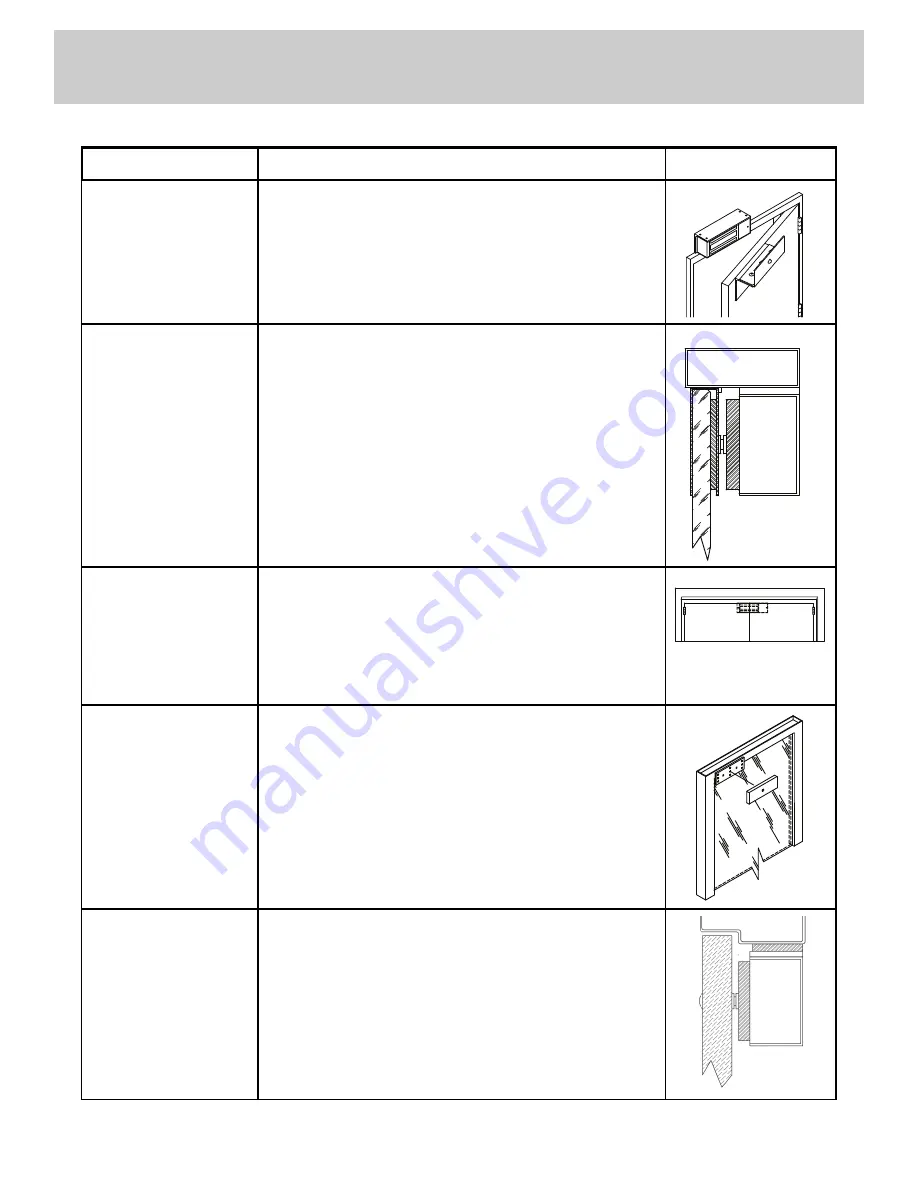

Top Jamb bracket and angle bracket kit for use when mounting

lock on a door that swings inwards. Magnet mounts to the

underside of an angle bracket mounted on the frame. Armature

plate mounts to “Z” bracket assembly mounted to door face.

Available for 8310 and 8320 models

Allows an armature plate to be mounted to a glass or Herculite

door that does not have a frame. The Glass Door Bracket is a “U”-

shaped piece of 1/16” thick material that slips over the top of the

glass panel and tightens to the glass with setscrews. The Armature

plate mounts directly to the surface of the bracket by means of a

threaded hole in the bracket assembly plate.

Available for both 1/2” and 3/4” thick glass doors.

Used for traffic control applications where two doors are to be used

with a single 8375 lock. The Split Armature plates are half the

length of a standard armature. Each of these is mounted on one of

a pair of doors with an 8375 lock centered on the frame between

the doors.

NOTE:

Use of split armature plates will reduce holding force.

For use with doors that do not permit the armature plate to be

mounted low enough to meet the magnet surface. Eg: Some

aluminum framed commercial glass doors. The armature holder

can be mounted to whatever frame is available and the armature

plate in turn mounted to the holder.

Available in both flat (shown) as well as Pocket styles.

For use when an obstruction in the door prevents the installation of

the armature plate at a proper height. If the armature plate needs to

be lowered then a spacer bar can be used to lower the lock from the

frame.

Available in several different heights.

Contact RCI for full details.

Top Jamb Bracket

Glass Door Bracket

Split Armature Plates

Armature Holder

Space Bar

Part

Usage

Example

8375 Installation Instructions

(Continued)

4

©2011 RUTHERFORD CONTROLS INT’L CORP. • WWW.RUTHERFORDCONTROLS.COM

USA: 2517 SQUADRON COURT, SUITE 104, VIRGINIA BEACH, VA 23453• CANADA: 210 SHEARSON CRESCENT, CAMBRIDGE, ON N1T 1J6

PHONE: 1.800.265.6630 519.621.7651 • FAX: 1-800482-9795 519.621.7939 • E-MAIL: SALES@RUTHERFORDCONTROLS.COM