72

ROUTINE CONTROL AND MAINTENANCE

OPERATIONS AND SAFETY CHECKS

1.

The machine must be inspected by a specialist technician who checks its safety or for any damage or defects in the following cases:

•

Before it is put into operation

• After

modifi cations or repairs

•

At regular intervals, as indicated in the «Routine maintenance and checks” table.

2.

Every six months check that the safety devices are in good working conditions; the inspection must be made by authorized specialist staff .

To ensure that the safety devices are properly operating , the machine must be overhauled by specialist staff or skilled workshop every 5

years.

3.

The person in responsable of the machine must make an annual check of its condition. During this checking, he must decide whether the

machine still complies with the technical safety regulations. After checking it has to apply on the machine a label of checking made.

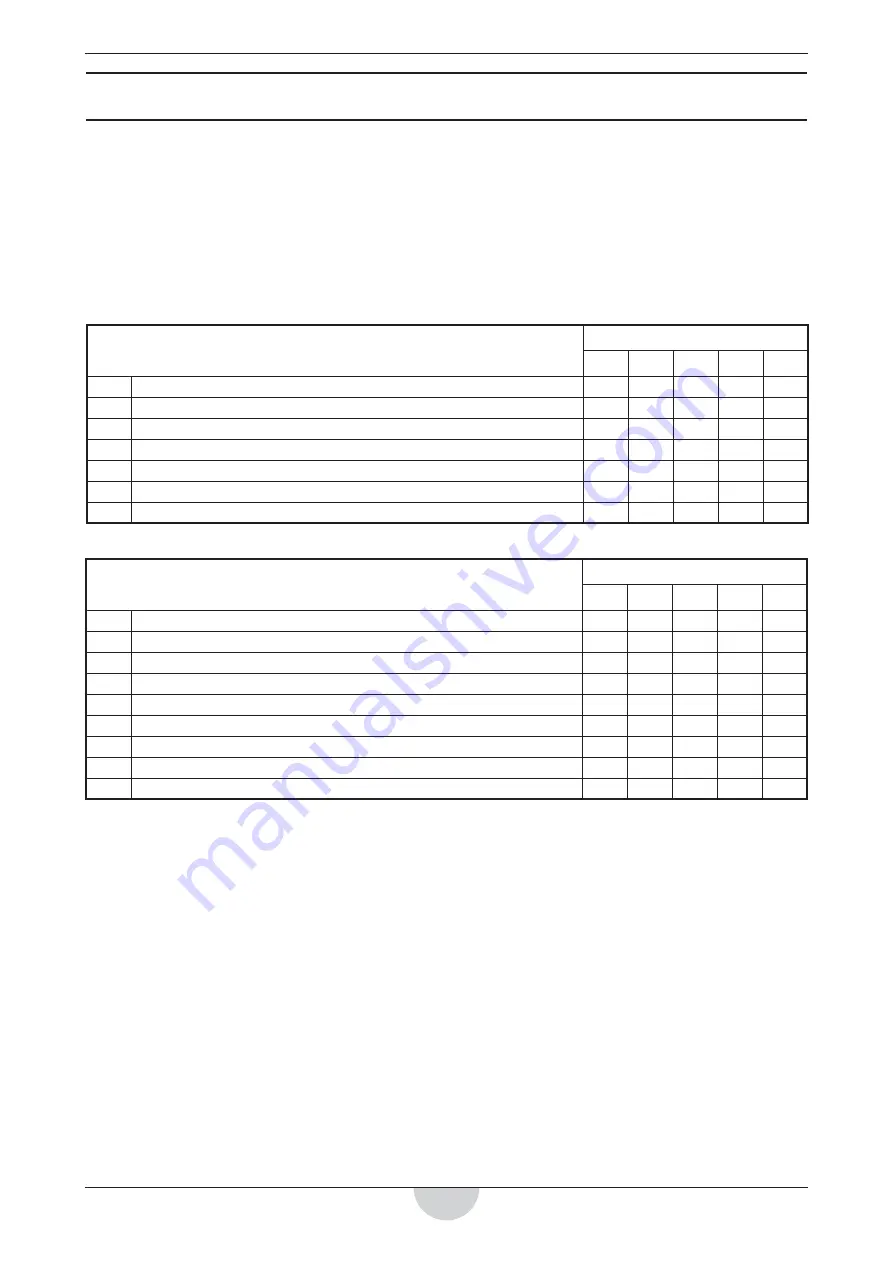

Periodical maintenance checks

(electric version)

Intervals in hours

8

40

125 150 1500

1

Check belts

x

2

Check that the main brushes is free fom wires, strings, etc.

x

3

Check dust fi lter

x

4

Replace dust fi lter

x

5

Check main and side brushes trace width

x

6

Check electrolyte of the battery

x

7

Check motor carbon brushes

x

Periodical maintenance checks

(petrol version)

Intervals in hours

8

40

100 150 1500

1

Check engine oil (*)

x

2

Check engine air fi lter (*)

x

3

Replace engine aire fi lter (*)

x

4

Check belts

x

5

Replace engine oil (*)

x

6

Check that the main brushes is free fom wires, strings, etc.

x

7

Check dust fi lter

x

8

Replace dust fi lter

x

9

Check main and side brushes trace width

x

(*) = See also the engine use manual of the constructor.

Summary of Contents for ALFA

Page 2: ...2 ...