36

ROUTINE CONTROL AND MAINTENANCE OPERATIONS

AND SAFETY CHECKS

!

Caution!

1. The motor-sweeper must be inspected by a skilled technician who checks its safety or for any damage or de-

fects in the following cases:

•

before it is put into operation.

• after

modifi cations or repairs.

•

at regular intervals, as indicated in the “Routine maintenance and control operations” table.

2. Every six months check that the safety devices are in good working order.

To ensure that the safety devices are operating properly, the machine must be overhauled by specialist staff every

5 years.

3. The person in charge of the machine must make an annual check on its condition. During this check, he must

decide whether the motor-sweeper still complies with the technical safety regulations, and then apply a mar-

ker plate to the machine to indicate that the check has been made.

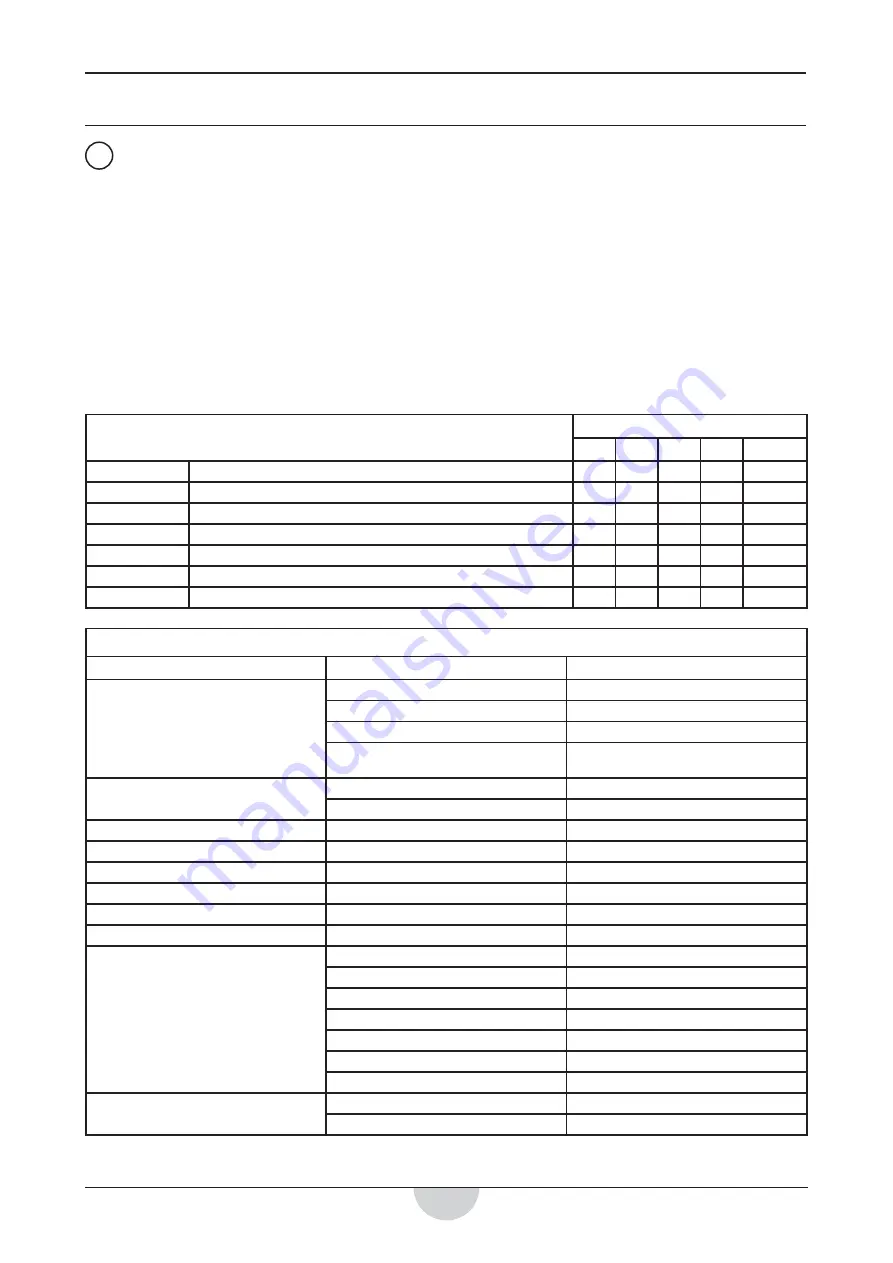

Periodical maintenance checks table

Intervals in hours

8

40

150

500

1500

1

Check belts

√

2

Check that the main brush is free fom wires, strings, etc.

√

3

Check dust fi lter

√

4

Replace dust fi lter

√

5

Check main and side brushes trace width

√

6

Check the battery liquid

√

7

Check motor brushes

√

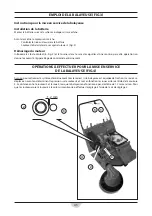

TROUBLESHOOTING

Fault

Cause

Corrective action

The motor-sweeper fails to pick up large parti-

cles of dirt or leaves traces of dirt behind.

Travel speed too high

Reduce travel speed

Brush pressure too light

Adjust brush pressure (trace on fl oor)

Brush worn

Lower or replace brush

Bristles bent, or string or wire, etc., entangled

in brush.

Remove string or wire and straighten bristles

in warm water.

Sweeper leaves dust on fl oor or dust comes

out from side fl aps.

Filter clogged

Clean fi lter

Flaps worn out or broken

Replace fl aps

Dust comes out of the suction fan

Filter torn

Replace fi lter

Motor-sweeper throws dirt forwards

Front fl ap broken

Replace front fl ap

The main brush lifts the front fl ap

Front fl ap too long

Replace front fl ap

Rapid brush wear

Excessive brush pressure

Reduce brush pressure (narrower trace).

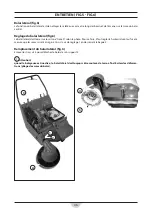

Main brush noise diff erent or excessive.

Material wound around brush

Remove entangled material

The main brush does not turn

Drive belt broken

Fit new drive belt

Battery does not maintain its charge

Electrolyte level low

Top up electrolyte level

Battery cell burned out

Replace battery

Motor over-loaded

Check motor current absorption

Battery terminals loose

Check and tighten battery terminals

Material entangled in main brush

Remove entangled material

Bearings seized

Replace bearings

Excessive brush pressure

Reduce brush pressure (narrower trace)

Battery discharges quickly

Insuffi

cient charge time

Increase charge time

Battery terminals loose or oxidized

Clean terminals and tighten

Summary of Contents for Brava 900 ET

Page 2: ...2...