63

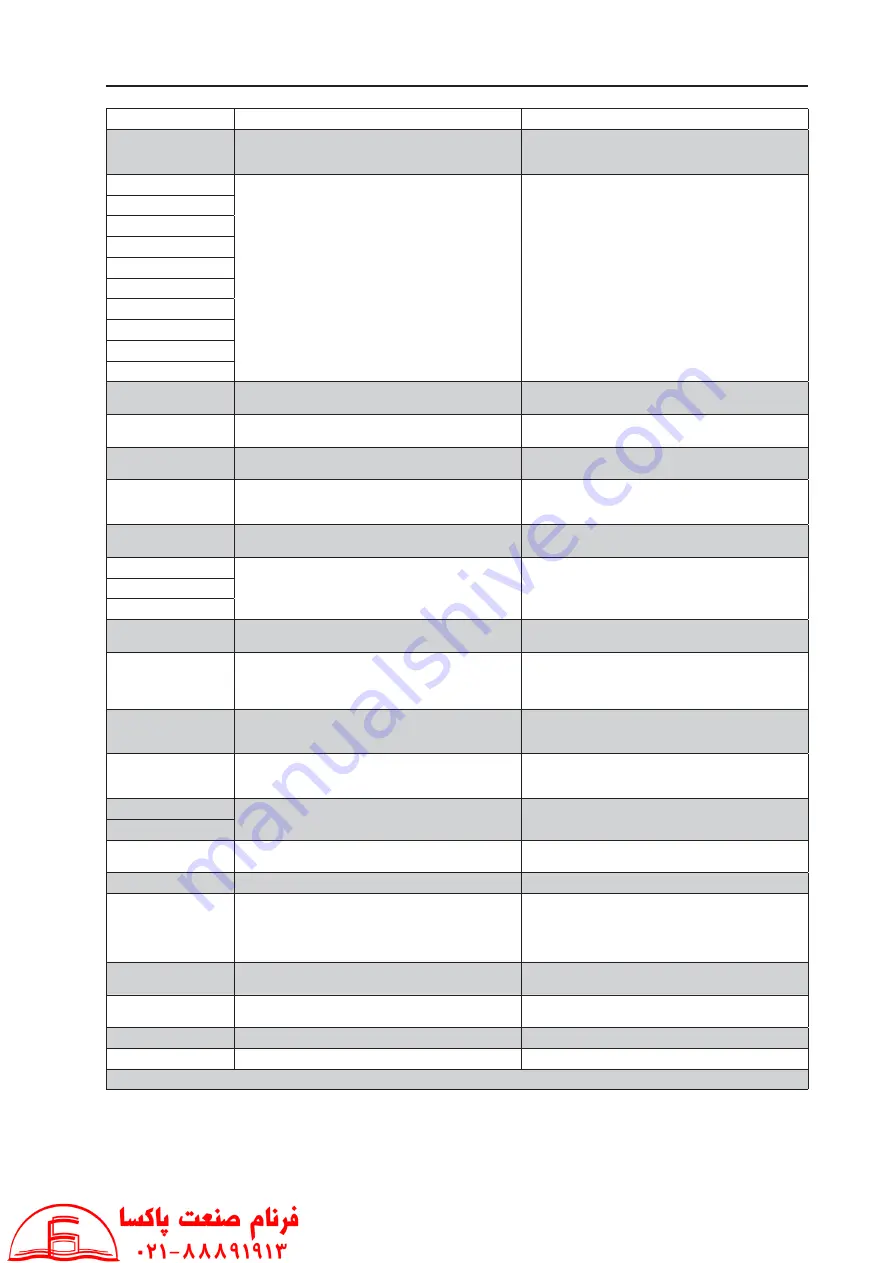

ERROR CODE

PROBLEM DESCRIPTION

CORRECTIVE ACTION

3214

A possible controller fault has been detected.

Fix whatever condition is causing the inhibit signal.

This could be related to the dirty water tank full switch,

or the clean water tank empty switch.

3601

A possible controller fault has been detected.

Try disconnecting the batteries, wait for 30 seconds,

then re-apply power and switch on. If the fault is still

exhibited, then replace the controller.

3602

3603

3608

3609

360A

360B

360C

360D

360E

3A00

A parameter has been programmed with an illegal

value.

Program controller with default factory parameter fi le

and power cycle.

7000

The machine has been started with the freewheel

switch active.

Check freewheel switch and associated wiring.

7001

The freewheel switch has been activated whilst in

drive.

Check freewheel switch and associated wiring.

7500

The communications have timed out between the

Trio+ and LCD Modules.

Check wiring and connections between the Trio+ and

LCD module. If the fault persists, then replace the

Trio+ or LCD module.

7600

The brush motor has been detected as open circuit.

Check brush motor connections and wiring.

Check motor carbon brushes.

7601

Excessive brush current has been detected.

Check brush deck for foreign objects.

Check brush motors rotate freely.

Check brush motors for binding, or bent shafts.

Check operation of deck raise and lower.

7602

7603

7604

Inhibit 2 active. This is likely to be inhibiting the

brushes.

This is a warning to indicate that an inhibit is active.

Check positioning and wiring of the inhibit switch.

7605

Excessive brush current detected on start-up.

Check brush deck for foreign objects.

Check brush motors rotate freely.

Check brush motors for binding, or bent shafts.

Check operation of deck raise and lower.

7700

The vacuum motor has been detected as open circuit.

Check vacuum motor connector is correctly inserted.

Check vacuum motor and wiring for continuity.

Check motor carbon brushes.

7701

Excessive vacuum current has been detected.

Check vacuum motor for obstructions or blockages.

Check vacuum motor rotates freely.

Check motor for binding or bent shafts.

7702

Excessive vacuum current has been detected.

Check vacuum motor and wiring for short circuits.

Check motor rotates freely.

7703

7800

The traction motor has been detected as open

circuit on start-up.

Check connections to traction motor.

7801

Excessive traction current detected.

Check traction motor and wiring for short circuit.

7802

Traction motor output is in foldback.

Check vehicle is not overloaded, or being driven on

too steep an incline.

Check traction motor for obstructions.

Check traction motor rotates freely.

Check motor for binding or bent shafts.

7803

Internal signals relating to the traction motor drive

have become unreliable. Likely to be caused by noise.

Check connections to the traction motor.

If the fault is still exhibited, then replace the controller.

7880

Traction speed switch inputs are not at the expected

levels.

Check wiring to the traction speed selection switch.

7900

Emergency Stop input has been activated.

Check wiring to the E-Stop switch.

7901

Belly button has been activated.

Check wiring to the belly button switch.

C

AUTION

! C

ONTACT

RCM

SERVICE

FOR

ANY

ERROR

CODES

NOT

LISTED

IN

THE

TABLE

.

Summary of Contents for JUMBO 1002 RN

Page 2: ...RCM ...

Page 3: ...ITA MANUALE USO E MANUTENZIONE GB INSTRUCTION AND MAINTENANCE HANDBOOK ...

Page 64: ...64 IMPIANTO ELETTRICO LINEA CRUSCOTTO FIG 15 ELECTRIC SYSTEM DASHBOARD LINE ...

Page 66: ...66 IMPIANTO ELETTRICO LINEA CENTRALE CRUSCOTTO FIG 15A ELECTRIC SYSTEM DASHBOARD MAIN LINE ...

Page 68: ...68 IMPIANTO ELETTRICO LINEA POSTERIORE FIG 15B ELECTRIC SYSTEM REAR LINE ...

Page 70: ...70 IMPIANTO ELETTRICO LINEA ATTUATORI PEDANA FIG 15C ELECTRIC SYSTEM ACTUATORS LINE BOARD ...

Page 72: ...72 1 FUSIBILI FIG 16 1 FUSIBILE GENERALE 150A ...