75

ROUTINE CONTROL AND MAINTENANCE OPERATIONS AND

SAFETY CHECKS

1) The scrubber must be inspected by a specialist technician who checks its safety or for any damage

or defects in the following cases:

•

before it is put into operation

•

after modifi cations or repairs

•

at regular intervals, as indicated in the «Routine maintenance and checks” table.

2) Every six months check that the safety devices are in good working order; the inspection must be

made by authorized specialist staff.

To ensure that the safety devices are operating properly, the machine must be overhauled by an

authorized workshop every 5 years.

3) The person in charge of the machine must make an annual check on its condition. During this check,

he must decide whether the motor sweeper still complies with the technical safety regulations. . After

checking it has to apply on the machine a label of checking made.

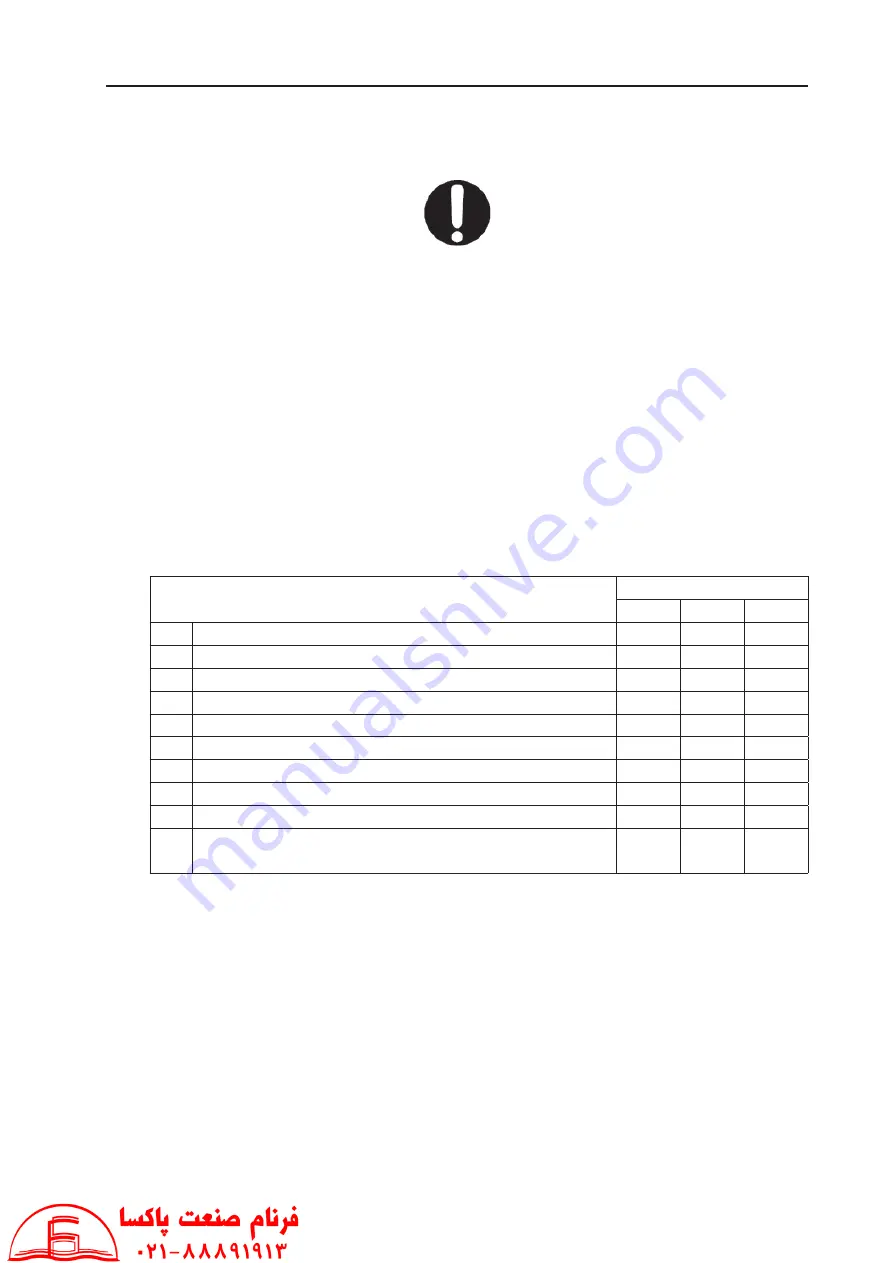

Periodic control and maintenance operationsto be carried out

every hours

8

40

200

1

Clean recovery tank

x

2

Clean suction motor fi lter

x

3

Check clean-water tank fi lter

x

4

Clean the clean water tank fi lter

x

5

Check cleanliness of suction pipelines and squeegee

x

6

Check state of brushes

x

7

Check condition of squeegee rubbers blades

x

8

Grease the steering system chain

x

9

Check the condition of the carbon elements in every motor.

x

10

Check the safety devices (microswitches, switches, horn,

emergency switch etc.)

x

Summary of Contents for JUMBO 1002 RN

Page 2: ...RCM ...

Page 3: ...ITA MANUALE USO E MANUTENZIONE GB INSTRUCTION AND MAINTENANCE HANDBOOK ...

Page 64: ...64 IMPIANTO ELETTRICO LINEA CRUSCOTTO FIG 15 ELECTRIC SYSTEM DASHBOARD LINE ...

Page 66: ...66 IMPIANTO ELETTRICO LINEA CENTRALE CRUSCOTTO FIG 15A ELECTRIC SYSTEM DASHBOARD MAIN LINE ...

Page 68: ...68 IMPIANTO ELETTRICO LINEA POSTERIORE FIG 15B ELECTRIC SYSTEM REAR LINE ...

Page 70: ...70 IMPIANTO ELETTRICO LINEA ATTUATORI PEDANA FIG 15C ELECTRIC SYSTEM ACTUATORS LINE BOARD ...

Page 72: ...72 1 FUSIBILI FIG 16 1 FUSIBILE GENERALE 150A ...