78

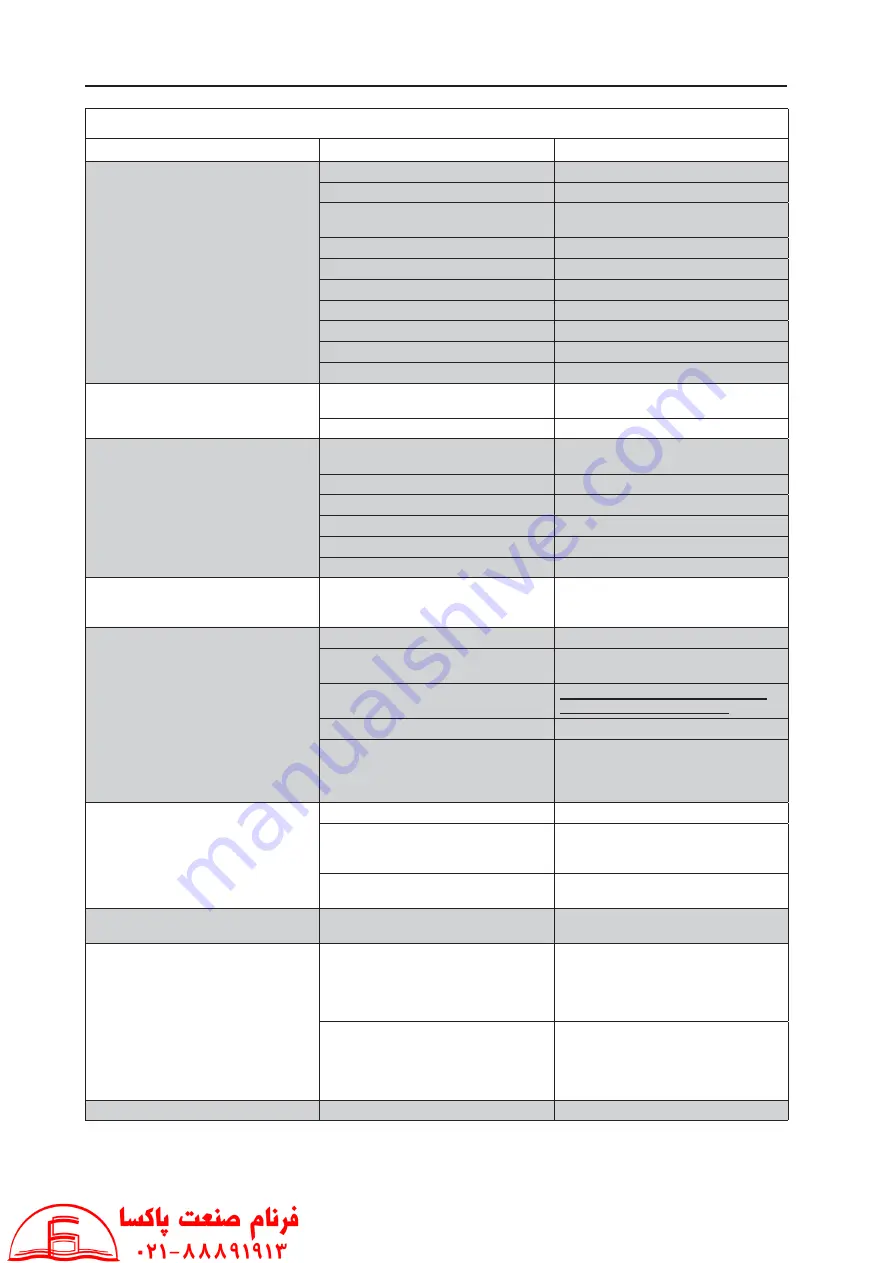

TROUBLESHOOTING

FAULT

CAUSE

REMEDY

Squeege does not dry perfectly.

Squeegee rubbers worn.

Replace rubbers.

Squeegee fouled.

Clean squeegee.

A foreign body has become jammed in

the squeegee.

Remove the foreign body.

Suction pipe fouled.

Clean pipe.

Squeegee not properly adjusted.

Adjust the squeegee. (fi g.8)

Water drain faucet open.

Close it.

Suction motor burnt.

Replace motor.

Suction motor carbon brushes worn.

Replace the carbon brushes.

Squeegee not lowered. Actuator faulty.

Replace actuator.

Suction fi lter 4 (fi g. 4) clogged.

Clean fi lter.

The detergent solution is not fl owing out

evenly onto the brushes.

Pipelines which supply water to the bru-

shes are fouled.

Clean pipes.

Filtro soluzione intasato.

Pulire fi ltro.

The detergent solution does not reach the

brushes or only a little is reaching them.

Tubazioni alimentazione acqua sulle

spazzole intasate.

Pulire tubazioni intasate.

Detergent solution fi lter fouled.

Clean fi lter.

Solution faucet does not opening.

Check faucet.

Feeding pipe squashed.

Restore pipe or replace

Tank without water.

Fill tank with water.

Brushes much worn.

Replace brushes.

The machine does not clean properly.

insuffi cent pressure of the brushes on

the fl oor due to the bad operation of the

potentiometer on the dashboard.

Replace potentiometer

The machine does not start.

Main key switch 7 (fi g.3) has not inserted.

Turn the key clockwise.

The battery fl at.

Check or charge the battery when the

display shows the problem.

Main fuse blown.

Before replace the fuse, contact the

RCM Authorized service staff.

Microswitch under seat faulty.

Replace the microswitch.

Emergency stop button pressed.

Release the button and repeat the start-

up procedure (see USING THE SCRUB-

BER/DRIER - scrubber/drier start-up

procedure).

The machine does not start or it stops

suddenly.

Batteries disconnected.

Connect batteries.

The operator has got up and the mi-

croswitch under the seat has cut off the

power supply to the system.

Sit down and operate the travel controls.

Display (diagnostics) on dashboard indi-

cates problem.

See “ELECTRONIC CONTROL UNIT”.

The machine does not travel forward or

reverse.

Connection of accelerator pedal 3 (fi g. 3)

disconnected or microswitch faulty.

Restore the connection or replace the

microswitch.

The suction motor switches off or does

not start.

The fl oat-switch on the recovery tank has

cut off the power to the suction motor;

this is indicated by the display showing

the fl ashing symbol of the full dirty water

recovery tank.

Turn off the suction motor immediately by

means of button 6 (fi g 3).

Empty the recovery tank.

Float switch fouled.

Release the fl oat switch and clean it to

remove the dirt. To do this open the lid 1

(fi g. 4), remove the suction fi lter 4 (fi g. 4)

then insert your hand for access to the

fl oat switch.

The machine has diffi culty moving.

Parking brake engeded.

Release the parking brake.

Summary of Contents for JUMBO 1002 RN

Page 2: ...RCM ...

Page 3: ...ITA MANUALE USO E MANUTENZIONE GB INSTRUCTION AND MAINTENANCE HANDBOOK ...

Page 64: ...64 IMPIANTO ELETTRICO LINEA CRUSCOTTO FIG 15 ELECTRIC SYSTEM DASHBOARD LINE ...

Page 66: ...66 IMPIANTO ELETTRICO LINEA CENTRALE CRUSCOTTO FIG 15A ELECTRIC SYSTEM DASHBOARD MAIN LINE ...

Page 68: ...68 IMPIANTO ELETTRICO LINEA POSTERIORE FIG 15B ELECTRIC SYSTEM REAR LINE ...

Page 70: ...70 IMPIANTO ELETTRICO LINEA ATTUATORI PEDANA FIG 15C ELECTRIC SYSTEM ACTUATORS LINE BOARD ...

Page 72: ...72 1 FUSIBILI FIG 16 1 FUSIBILE GENERALE 150A ...