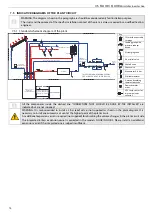

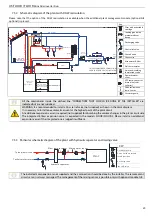

US FLOOR / FLOOR

Minichiller inverter Duo

14

1

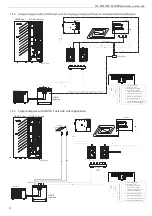

Positioning on the floor

Provide lifting from the floor of the unit:

•

20 mm without conveying the condensate drain

•

90 ÷ 100 mm to allow the conveying of the

condensate drain

In case of installation in areas subjected to extreme cold

or heavy snow, where there is the possibility of freezing,

it’s recommended to provide suitable frost protection

systems.

(A) Level

(1) condensate drain pipe

Suspended positioning

•

In the case of suspended installation, adequate

brackets must be used to support the weight of

the unit and also depending also on the type of

the wall to which should be fixed.

•

Make sure that the section of the wall doesn’t

overlap to bearing elements of construction,

pipelines or power lines.

(2) brackets for positioning (not supplied with the unit)

Both units must be positioned on a leveled surface, the holders used for installation must be able to support its

weight.

7.4

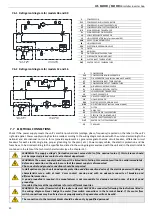

HYDRAULIC CONNECTIONS

The hydraulic connections have to be installed in accordance with national and/or local regulations; pipes can be made up of steel,

galvanized steel or PVC. Pipes have to be designed depending on the nominal water flow and on the hydraulic pressure drops of

the system. All pipes have to be insulated with closed-cell material of adequate thickness. It is recommended to connect the

indoor unit to the piping using flexible joints. The hydraulic circuit should include the following components:

•

Hole thermometers to monitor the circuit’s temperature.

•

Manual shut-off valves to separate the chiller from the hydraulic circuit.

•

Charging group and discharge valve.

•

Anti-vibration joints and supports for the piping where necessary.

WARNING: make sure that the size of the pipes shall not exceed the maximum head loss on the plant side given in

the table in the Paragraph 15.3 (see the available pressure head data).

WARNING: connect the pipes to their attacks always by the way of key against key method.

WARNING: The plant side expansion vessel included in the models FLOOR/FLOOR-S has a limited capacity of 8

liters. The installer should verify that if the expansion vessel is adequate to the real capacity of the plant circuit,

otherwise should be provide an additional expansion vessel.

For the installation position of the expansion vessel (indicated as additional expansion vessel), please refer to

Paragraph 7.5.

WARNING: check that the weight of the pipes does not grave about the structure of the machine.

WARNING: unit water return pipe should be in correspondence with the connection labelled: ”TECHNIC WATER

RETURN”, otherwise the evaporator may freeze.

WARNING: If the water flow switch (factory mounted) is altered or removed, the warranty will no longer be valid.

Please refer to the wiring diagram for the water flow switch electric connections.

The metallic Y-filter with 1 mm mesh must be kept clean, so make sure that it is still clean after the installation of

the unit, and then check it periodically.

The water on the charging/topping-up pipe must be opportunely pre-filtered from any suspended particles and

impurities through the use cartridge filter (washable, wrapped wire, etc.) of at least 100 microns.

Check the water hardness with which you load and top up the plant circuit. With particularly hard water, in this

case it is necessary to utilize a water softener. For treating water for the plant, please refer to UNI 8065.