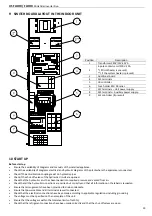

US FLOOR / FLOOR

Minichiller inverter Duo

40

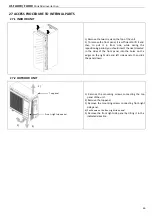

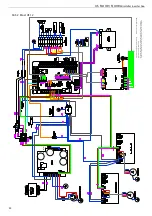

21.5 MAINTENANCE OF THE CIRCULATOR PUMP

For removing and/or working on the circulator pump you don’t need necessarily to

evacuate the plant circuit, just stop the fluid to flow from both upstream and

downstream sides by closing the ball valve (1) (by rotating the knob clockwise) and

closing the flow regulator valve (2) (horizontal calibration pin).

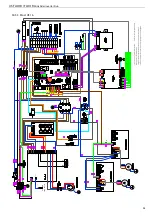

21.6 FACTORY SETTINGS OF THE CIRCULATOR PUMP

The circulator pump is already factory set for optimal operation.

The factory setting requires rotating the slot of the red knob at the blue symbol position

showing the indication of the floor plant (rotating the knob completely counter

clockwise).

It is not recommended to change this setting.

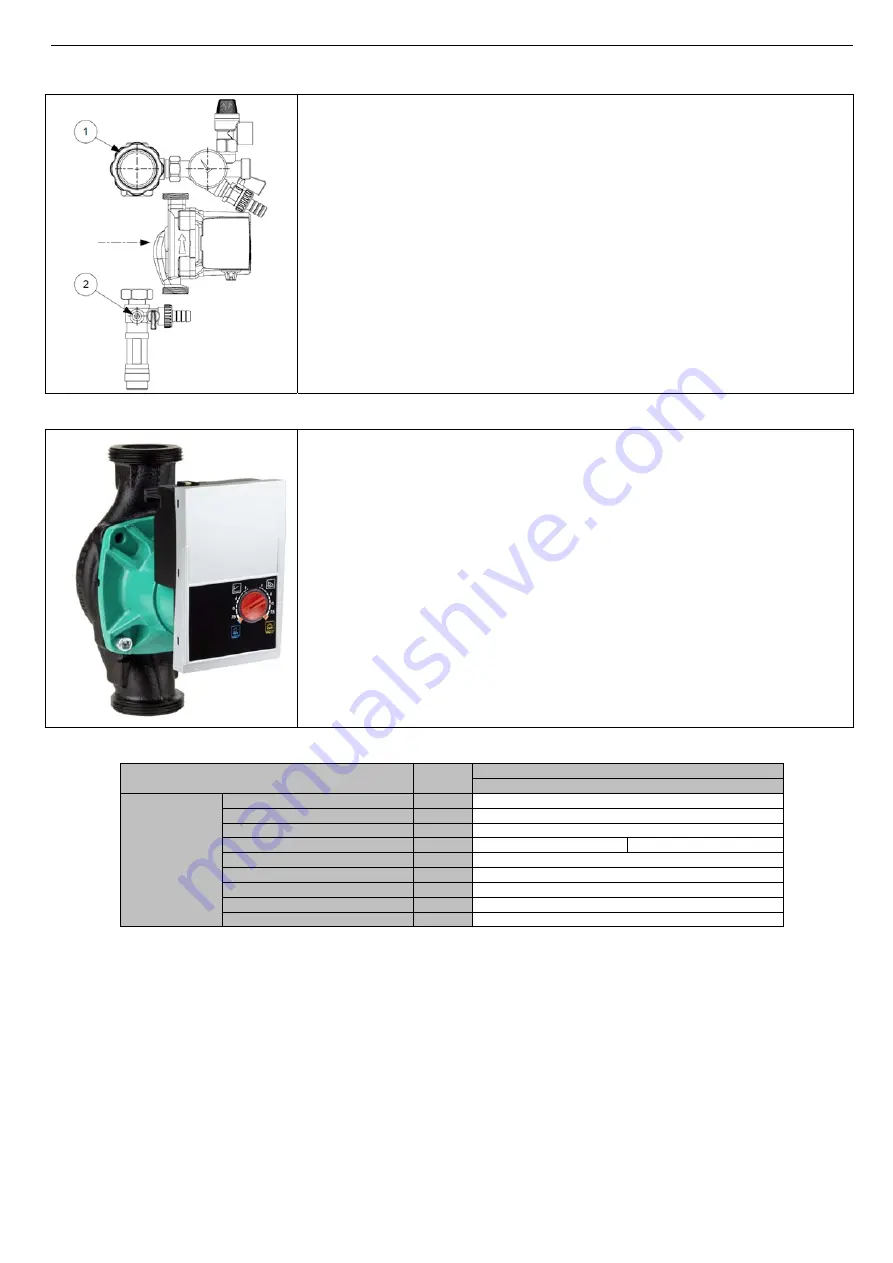

21.7 TECHNICAL CHARACTERISTICS

TECHNICAL CHARACTERISTICS

Unit

Model

FLOOR-S

Solar circuit

Maximum water flow

m

3

/h

0,7

Maximum pressure of solar circuit

bar 6

Maximum temperature

°C 120

Maximum solar surface

m

2

20 for PLAN collector

15 for collector under vacuum

Solar exchange coil surface

m

2

0,7

Maximum head of the pump

kPa

74

Maximum power of the pump

W

75

Maximum absorbed current of the pump

A

0,60

Energy Efficiency Index (EEI) pump

≤

0,21

22

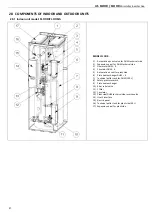

OPTIONAL DHW TECHNICAL SIDE BOILER KIT

The indoor unit in all its versions can be coupled to other external energy source in addition to the solar energy source, such as:

gas boiler, pellet boiler and any other energy source that it is implementable in the control with the characteristics of having a

proper circulator and working with a variable

∆

T without exceeding 20-25°C. The kit provides the internal pipes of connection

between the DHW technical side puffer tank and attacks disposed for the installation. The installer must provide the required

hydraulic connections for connecting the indoor unit with the auxiliary energy source as described in Paragraph 7.4.2, and control

setting as described in the manual cod. 9120523.XX.