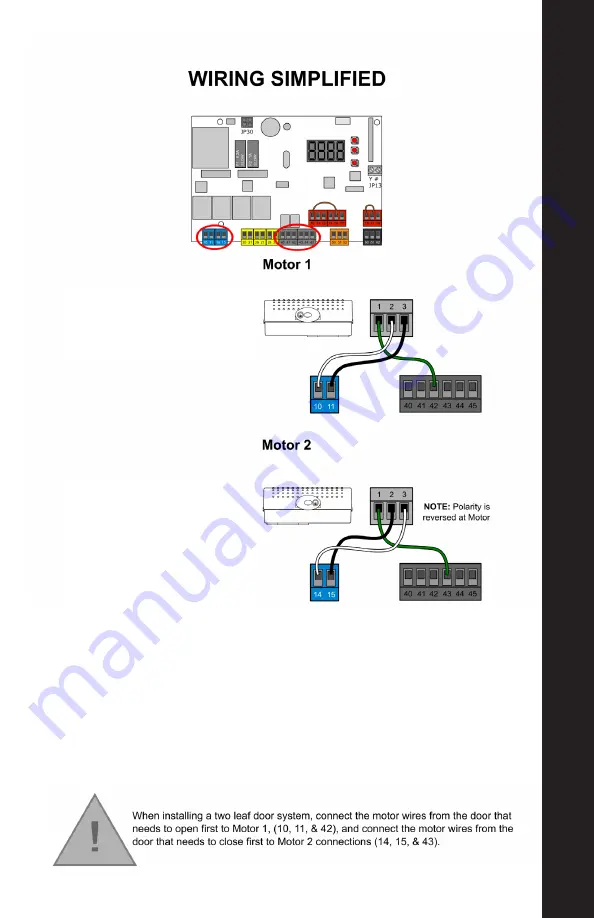

Motor 1 is the door that will

open first and close last.

For Single door application

please only use Motor 1 wiring.

Connect Motor wires to motor

ouput terminal 10 and 11, and

the limit input at terminal 42.

Motor 2 is the door that will

open last and close first.

For

dual motor installations this

will be your second motor.

Motor 2 output terminals are

14 and 15, and the limit input

is terminal 43

10

WIRING SIMPLIFIED