RealMan (Beijing) Intelligent Technology Co., Ltd.

68

4, which represents the level of the robot's collision sensitivity. The higher the level, the

more sensitive it is to the collision. The default collision level on the mechanical arm is

0, that is, there is no collision detection.

Note: The user should make reasonable choice when setting the collision protection

level. The higher the level is, the higher the probability of the mechanical arm to detect

a false collision will be. In addition, if the end of the robot changes the load, the dynamic

parameters of the robot must be recalibrated, otherwise the situation of false collision

will also occur.

4. Installation Method

There are three ways to install the robot arm, i.e., lifting, mounting and side mounting.

The internal algorithm of the robot arm is different, and the user needs to configure the

motion parameters according to the actual installation method.

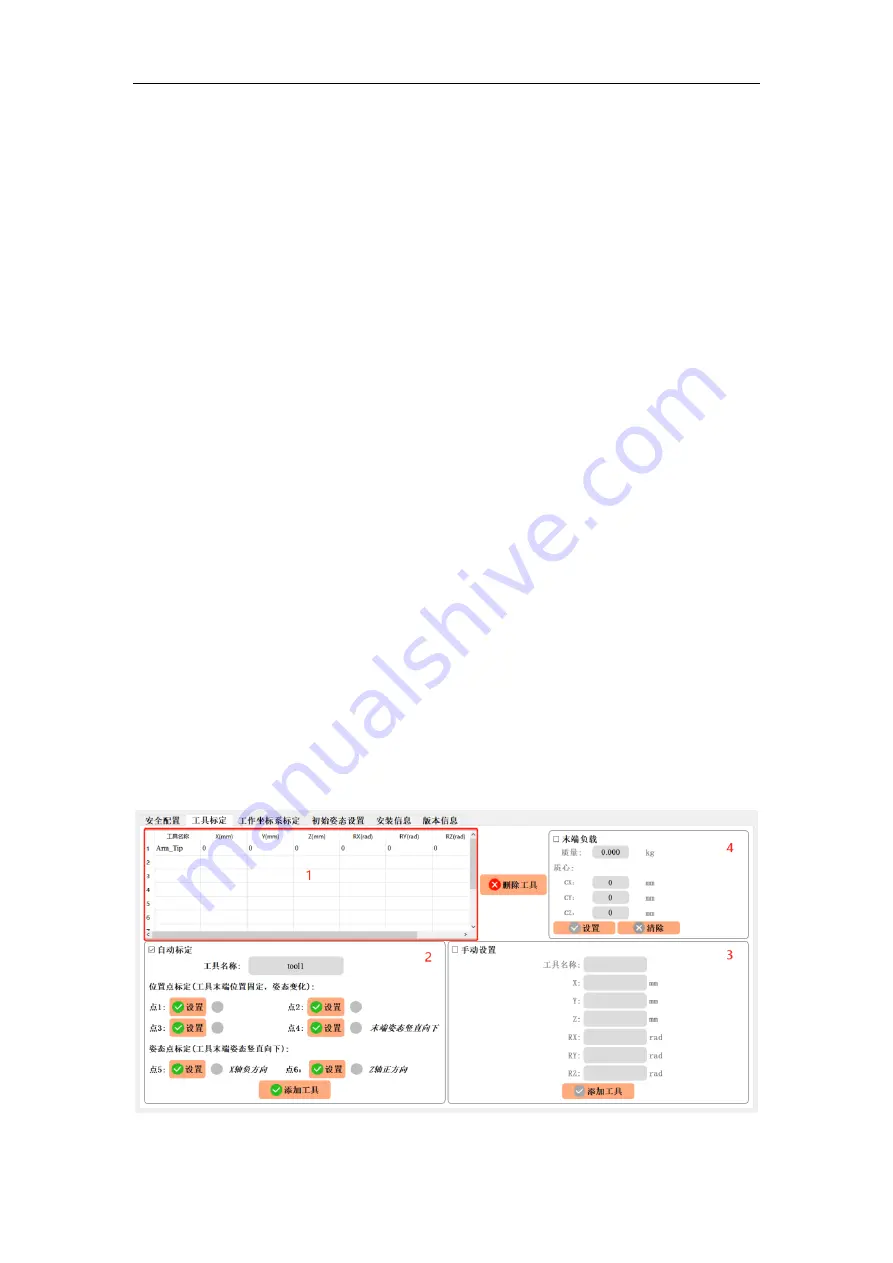

8.4.2.2 Calibration of the Tool-End Coordinate System

Tool-end or tool coordinate system calibration is shown in the figure below. Region 1

displays all current tool coordinate system and tool pose information. Region 2

automatically calibrates the current tool coordinate system. Region 3 manually sets the

tool coordinate system information.

Fig. 8-55 Calibration of the tool coordinate system.