18

REC Installation Manual - REC Solar Panels - IEC

61215

/

61730

Rev L

-

09

.

21

Ref: PM

-

IM

-20

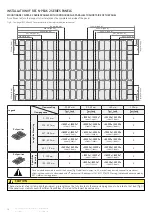

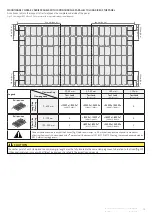

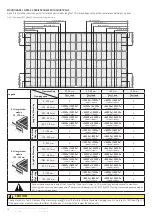

DRAINAGE HOLES

On the long and short sides of the REC frame small drainage holes can be found that allow humidity and water to exit the frame easily and minimize

damage (fig.

16

). These are spaced

55

mm from the corner on

60

-cell format panels and

60

mm on

72

-cell format panels. These holes must not be

used for mounting the panel, and they must not be covered by any part of the mounting structure.

To enable e

ff

ective drainage and ensure there is

no damage to the panel, the drainage holes must remain fully open and enable water egress during and a

ft

er installation. The shape and dimensions

of the drainage holes may vary depending on product and/or frame design.

GROUNDING

Local regulations may require grounding of the panels. Grounding must be done using an electrical connection from the panel frame. REC solar

panels have a small round grounding hole positioned near each corner of the panel on both the long side and the short side,

as shown in fig.

16

and

can be further

identified by the grounding symbol stamped in the frame next to it. Check all applicable requirements before beginning installation:

• Suitable grounding clips, lugs or other constructions must be used,

• A

tt

ach grounds to the grounding holes in the panel frames,

• Follow the grounding device manufacturer’s installation instructions to ensure a safe and conductive connection, including any

supplementary hardware, e.g., star washer, and tighten according to recommended torque,

• Where common grounding hardware (nuts, bolts, star washers, split-ring lock washers, flat washers and the like) are used to a

tt

ach a grounding

device, the a

tt

achment must be made in conformance with the grounding device manufacturer’s instructions.

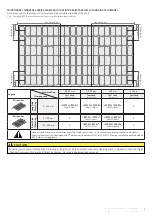

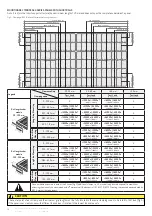

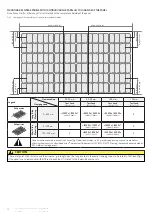

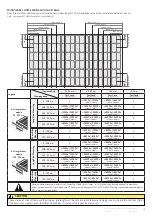

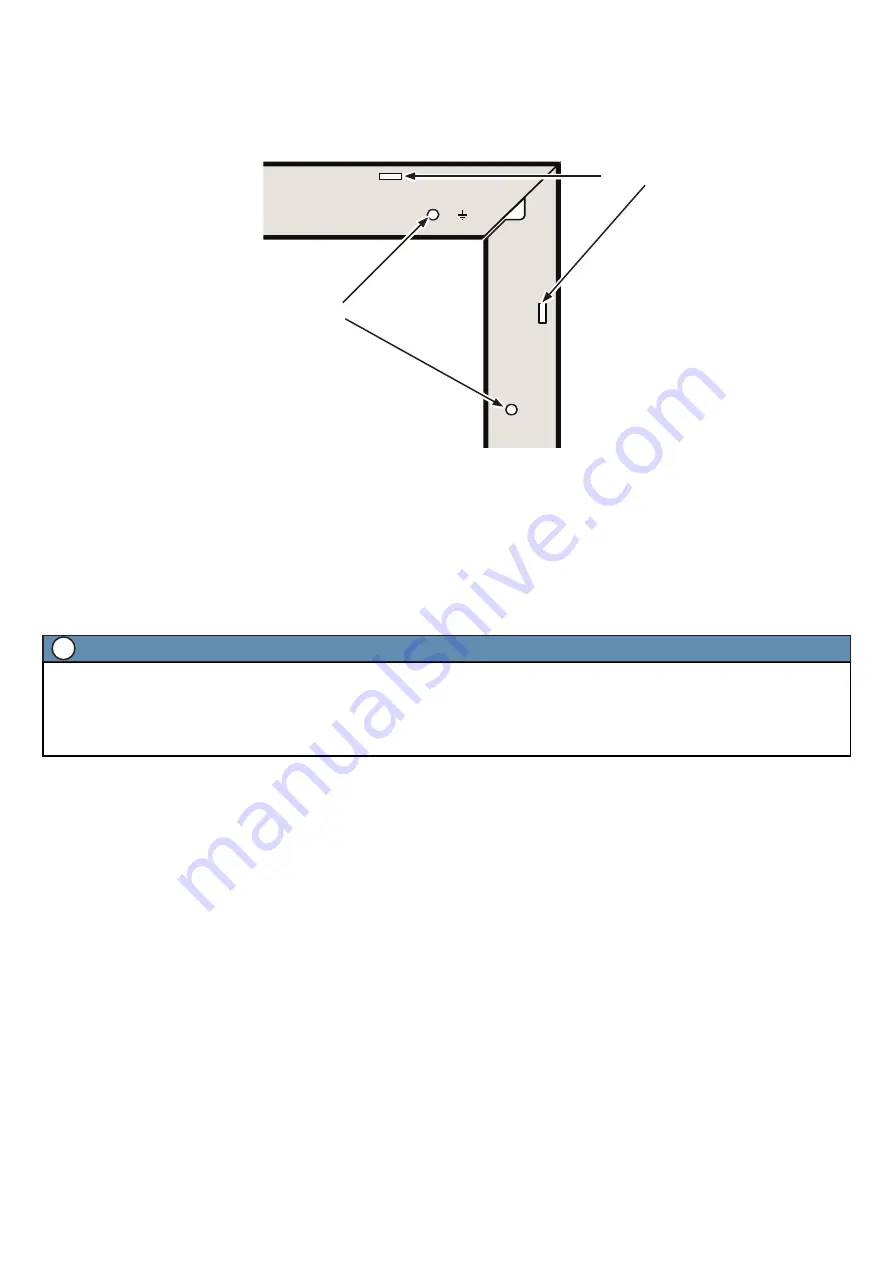

Fig.

16

: Drainage and grounding holes

25.6- 0 [650 - 0 mm]

GR

GR

GR

GR

0-25.6 in [0 - 650 mm]

9.8 - 4 in

[250 - 100 mm]

4 - 9.8 in

[100 - 250 mm]

9.8 - 4 in

[250 - 100 mm]

4 - 9.8 in

[100 - 250 mm]

25.6- 0 [650 - 0 mm]

0-25.6 in [0 - 650 mm]

NOTE

• To avoid galvanic corrosion, galvanized or hot dipped zinc plated fasteners are preferred, however stainless steel fastening materials are

equally suitable.

• The support bars across the rear of REC panels are connected to the frame via specially designed grounding clips and do not need to be

individually grounded.

• Negative grounding of the panels is not required by REC.

i

Grounding holes

Drainage holes