6

REC Installation Manual - REC Solar Panels - IEC

61215

/

61730

Rev L

-

09

.

21

Ref: PM

-

IM

-20

ELECTRICAL INSTALLATION

ELECTRICAL REQUIREMENTS

Application Class

REC solar panels are rated for use in electrical Application Class A, Protection Safety Class II; at hazardous levels of voltage (>

35

V), current(>

8

A)

and power (>

240

W) where general contact access is anticipated (panels qualified for safety through IEC

61730

-

1

and -

2

).

System Requirements

REC solar panels are only for use where they meet the specific technical requirements of the complete system. Ensure other components will not

cause mechanical or electrical damage to the panels. Only panels of the same type and power class should be connected.

String configuration

When connecting panels in a string, plan and execute according to the inverter manufacturer’s instructions. The number of panels connected to an inverter

must not exceed the voltage limits and operating range permi

tt

ed by the manufacturer, nor under any circumstance exceed the maximum system voltage

as stated in the technical specifications for the product at the rear of this manual. The maximum system fuse rating (overcurrent protection rating) and

the maximum reverse current for each panel can be found in the technical specifications for the product at the rear of this manual.

The maximum number of panels in a string can be calculated by dividing the maximum system voltage of the panel by its V

OC

accounting for the lowest

ambient temperature at site, e.g.: for a

1000

V system, if the lowest ambient temperature is

15

°C, the panel has a V

OC

of

40

.

8

V and a temperature coe

ffi

cient

of V

OC

of -

0

.

27%

/°C, the maximum panels per string is

23

(

∆

T°C =

25

° -

15

° =

10

°;

10

° x

0

.

27

=

2

.

7%

;

40

.

8

+

2

.

7%

=

41

.

9

;

1000

V /

40

.

4

=

23

.

9

, so a total

of

23

panels or

974

V). Qualified system designers can make exact calculations that account for specific project requirements and site conditions.

String connection

Panels connected in series must have the same ampere rating. The maximum number of panels that can be connected in series or parallel depends upon

system design, inverter type and environmental conditions. String configuration must correspond to the specifications of other system components e.g.,

inverter. Refer to the reverse current rating of the panel indicated in the technical characteristics at the rear of this manual or on the panel datasheet.

Wiring layout

To minimize voltage surges (e.g., indirect lightning strikes), cables of the same string must be bundled together so loops are as small as possible.

String configurations must be checked before commissioning. If open circuit voltage (V

oc

) and short circuit current (I

sc

) deviate from specification,

this may indicate a configuration fault. Correct DC polarity must be observed at all times.

Electrical Ratings

Electrical ratings are within a specific tolerance of measured values at Standard Test Conditions (STC) as given in the technical characteristics for each

panel at the rear of this manual. Allow for increased panel output as a result of conditions di

ff

erent to STC by multiplying the I

SC

and V

OC

values by a

factor of

1

.

25

(or according to local regulations) when determining component voltage ratings, conductor ampacities, overcurrent device ratings and

size of controls connected to the PV output.

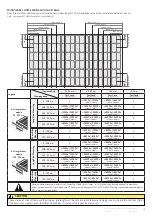

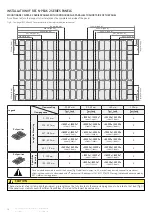

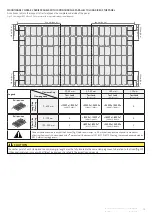

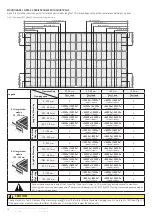

MECHANICAL INSTALLATION

FIRE GUIDELINES

The REC solar panels covered by this manual have a Class C (referencing UL

790

) fire classification. The REC solar panels in

60

-cell format are

rated Type

2

fire classification according to IEC

61730

-

2

:

2016

(ref. ANSI/UL

1703

); The REC solar panels in

72

-cell format are rated Type

1

fire classification according to IEC

61730

-

2

:

2016

(ref. ANSI/UL

1703

). Utilize the following fire safety guidelines when installing REC solar

panels:

• Check with all relevant local authorities for fire safety requirements for any building or structure on to which the panels will be installed,

• The system design must ensure that it can be easily accessed in the event of a building fire,

• Check with relevant authorities for applicable regulations concerning setbacks or other placement restrictions that may apply for roof-

mounted arrays,

• The use of DC ground fault interrupters is recommended. This may also be required by local and national codes,

• All electrical appliances are a fire risk. The panel must be mounted over a fire retardant roof covering rated for the application and a distance

of at least

20

mm (

40

mm for REC solar panels in

72

-cell format) between the panel and the mounting surface, to allow the free circulation

of air beneath the panels at all times.

ORIENTATION

The optimal mounting position of a panel results in the sun’s rays falling perpendicular (i.e., at

90

°) to the surface. To maximize system output, panels

should be installed at the optimum orientation and tilt angle. The specifics of this depend on location and can be calculated by a qualified system

designer. All panels in a string should, wherever possible, have the same orientation and tilt to ensure the system does not underperform due to

mismatched outputs. Dependent on local conditions, a lower angle of installation will potentially increase the requirement for regular cleaning.

DANGER

-

Electrical shock

Safety is paramount when working on the electrical installation. Always follow the electrical requirements to avoid the risk of sparking, fire hazards,

burns and lethal electric shocks

.

NOTE

The IP rating of the junction box provides a level of protection that allows panels to be mounted in any orientation.

i