REC Installation Manual - REC Solar Panels - IEC

61215

/

61730

Rev L

-

09

.

21

Ref: PM

-

IM

-20

7

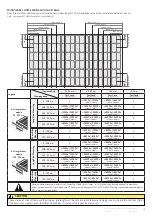

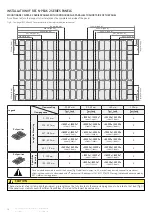

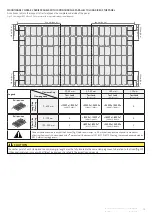

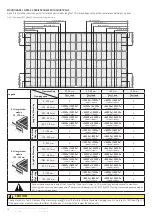

PANEL INSTALLATION

REC solar panels are designed for capturing solar radiation and can be installed where they conform to all local structural regulations. If installing

REC solar panels in overhead or vertical constructions, the installer must ensure that all local building codes and regulations specific to such

installations are correctly followed. There are di

ff

erent options for securing REC solar panels depending on the design of the array.

Mounting

hardware is not supplied by REC.

Ensure the mounting structure can withstand anticipated wind and snow loads.

Follow the mounting hardware

manufacturer’s instructions and recommendations at all times.

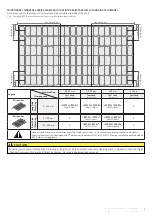

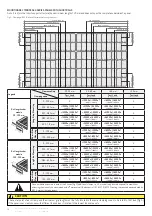

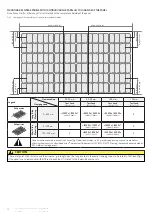

SECURING OF PANELS

A typical installation of solar panels will be carried out with suitable rails and clamps. Other types of panel support, e.g., plates, must meet the same

specifications. Such installations have been found to be in compliance with IEC

61215

& IEC

61730

requirements for the maximum stated test

loads which can be found for each individual panel type in the Panel Characteristics section at the end of this manual. Site-specific factors such as

high wind or snow levels must be taken into consideration to ensure this limit is not exceeded.

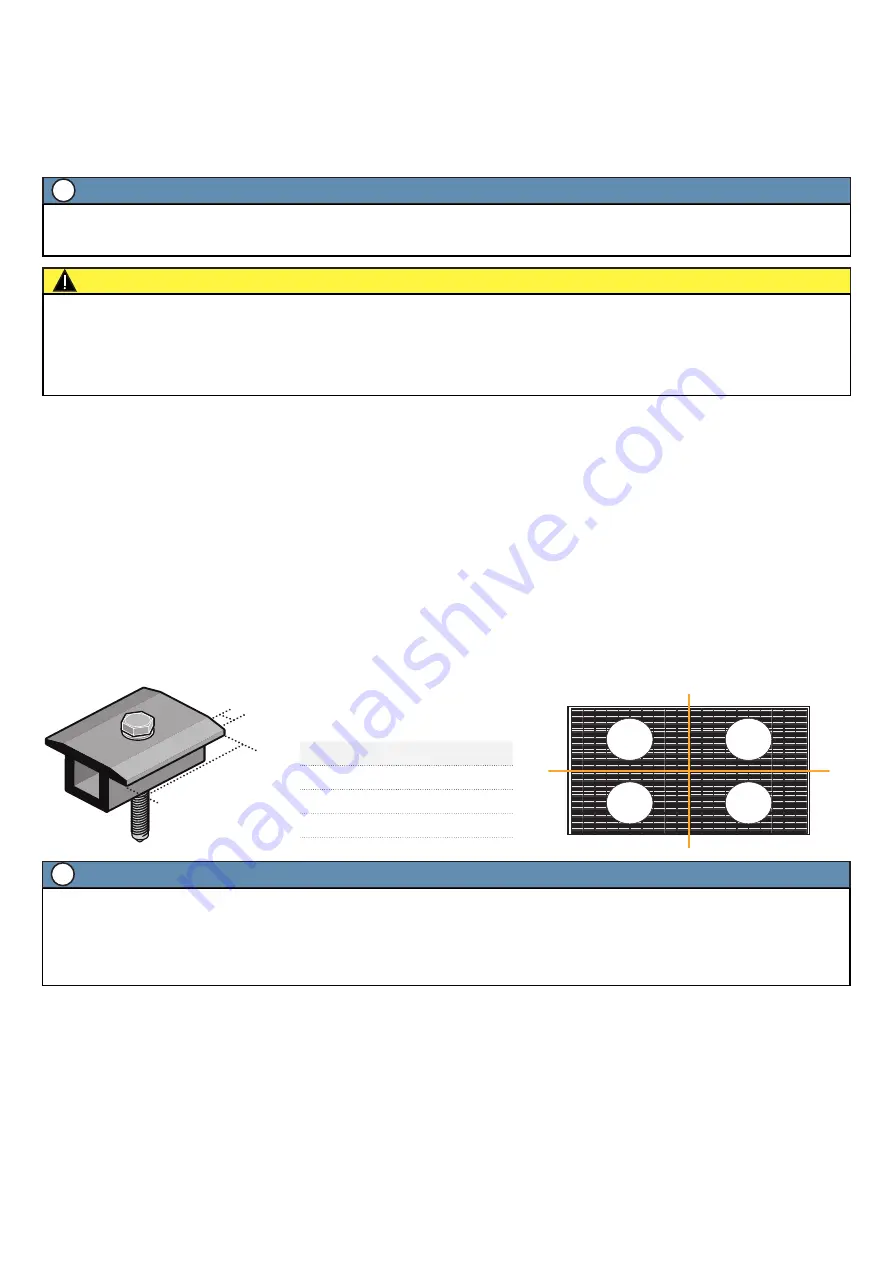

When installing on mounting rails, ensure they run underneath the panel and provide support to the frame. The positioning of the rail must ensure

that the minimum clamp grip length (fig.

1

) and the central point of the fixation, e.g., the bolt, is fully within the required clamping zone as indicated

on the following pages.

REC modules must be secured with a torque as shown in the table below (fig.

1

). Clamp installation must be carried out according to the

manufacturer’s instructions, including specific hardware and torque requirements. Ensure the clamps used are suitable for the planned installation

and expected system design loads.

• The grip area must not extend onto the panel glass and/or cause cell shading,

• Avoid the application of excessive pressure to prevent frame deformation,

• The panel must be secured, e.g., clamped, at least once in each of the four marked zones shown below (fig.

2

).

Fig.

1

: Clamp specifications

Fig.

2

: Panel quarter divisions

1

2

4

3

Min. grip length

Grip depth

NOTE

• In areas of snow build-up, panels can be subjected to forces in excess of the stated limit even when snow depth does not appear extreme,

potentially causing damage to the panel. If the installation may be a

ff

ected by this, further panel support is recommended, especially on the

lower row of panels.

• In the case of any questions regarding mounting systems, or if the mounting system to be used does not match any of the instructions shown

in this installation manual, please contact REC for further support.

i

Specifications

Length

Grip depth

5

mm -

10

mm

Min. grip length

40

mm

Torque

12

-

25

Nm

NOTE

Panels must be installed so that the cells are not shaded as this will drastically reduce electrical output. If partial shading is inevitable at certain

times of the day or year, it must be kept to an absolute minimum. Remove any labels or stickers that may be on the front of the panels and ensure

no residue is le

ft

on the glass.

i

CAUTION

There must be a minimum clearance gap between the uppermost part of the installation surface (e.g., roo

ft

op) and the lowest part of the panel

(i.e., underside of panel frame) to avoid any damage to the panel and to ensure su

ffi

cient airflow for cooling, helping to improve performance.

Minimum clearance gap

60

-cell format REC solar panels:

20

mm

Minimum clearance gap

72

-cell format REC solar panels:

40

mm

The surface below the panels must be kept clear of any objects that may cause damage to the panel.