15

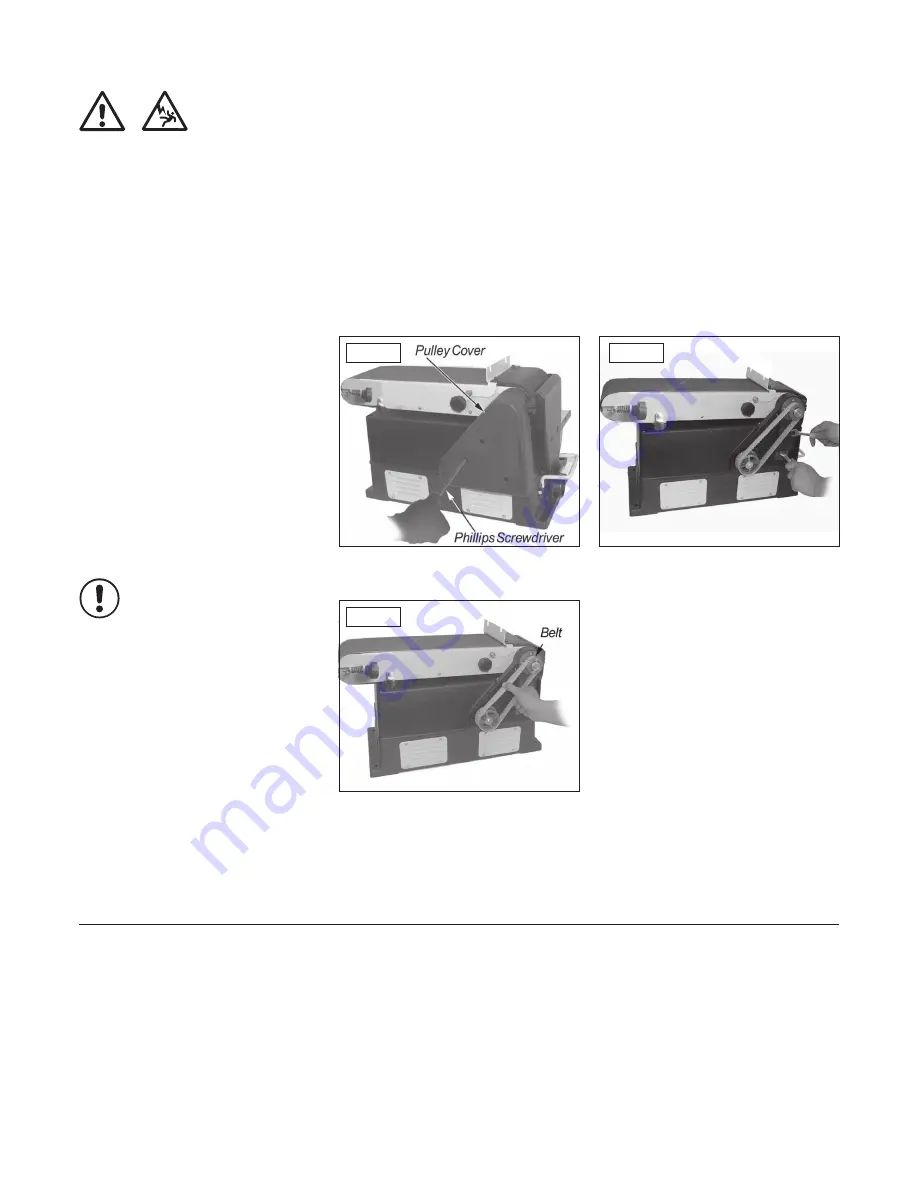

Warning: For your safety, remove the plug from power source

outlet before adjusting or maintaining the belt and disc sander.

Frequently blow out or vacuum out any dust that may accumulate inside the

motor. A coat of automobile-type wax applied to the worktable will make it

easier to feed the work while finishing.

Do not apply wax to the abrasive belt table because the belt could pick up

the wax and deposit it on the pulleys, causing the belt to slip.

Lubrication

The ball bearings in this machine are packed with grease during

manufacture. They require no further lubrication.

11. Maintenance

Changing the Drive Belt

1. Using a Phillips screwdriver remove 3 pan

head screws located in the cover,

Fig 11.1

.

2. Remove the cover.

3. Loosen 4-M8 hex head screw with wrench

to allow pulley to shift enough to place belt

around them. Place belt around motor pulley

and drive pulley as shown.

4. Adjust tension of the belt by putting a wrench

in adjusting gap. Push up on wrench to tighten

tension between pulleys,

Fig 11.2

.

5. Tighten 4-M8 hex head screws careful.

6. Test belt tension by placing fingers on either

side of the belt and squeeze. There should be

about a 6mm give on the belt,

Fig 11.3

.

Please note: Excessive tension on the

pulley belt may cause increased noise and

overload the motor. Excessive movement

on pulley belt may cause the belt to fail

prematurely.

7. Locate the pulley cover and position inside the

recessed edges of pulley housing.

8. Using a Phillips screwdriver, reinstall and

tighten 3 pan head screws.

12. Troubleshooting

PROBLEM

PROBABLE CAUSE

REMEDY

Sander does not operate.

Not plugged into power outlet.

Plug into power outlet.

Power switch defective.

Replace switch.

Motor or wiring problem.

Have qualified electrician carry out repair.

Motor slows when sanding.

Timing belt too tight.

Decrease tension.

Applying too much pressure.

Apply less pressure to the workpiece when sanding.

Wood burns while sanding.

Sanding disc or belt is loaded with debris.

Clean or replace disc or belt.

Sander makes excessive noise.

Timing belt too tight.

Decrease tension.

Bearing worn.

Replace bearing.

Fig 11.1

Fig 11.3

Fig 11.2

i

Kg

i

Kg

i

Kg