27

14. Maintenance - Cont.

7. Check the blade tracking on the newly fitted blade by

turning the upper wheel by hand. To track the blade

loosen the locking knob on the back of the machine

and turn the tracking knob clockwise to move the blade

back and anti clockwise to move the blade forward. The

blade should run as close to the centre of the bandwheel

as possible. When the blade is tracked correctly make a

final check to ensure that the blade tension is adequate

for the type of blade being used.

8. Re-set the blade guides.

9. Close and lock both the bandwheel doors, refit the fence

rail and rip fence before re-connecting the power supply.

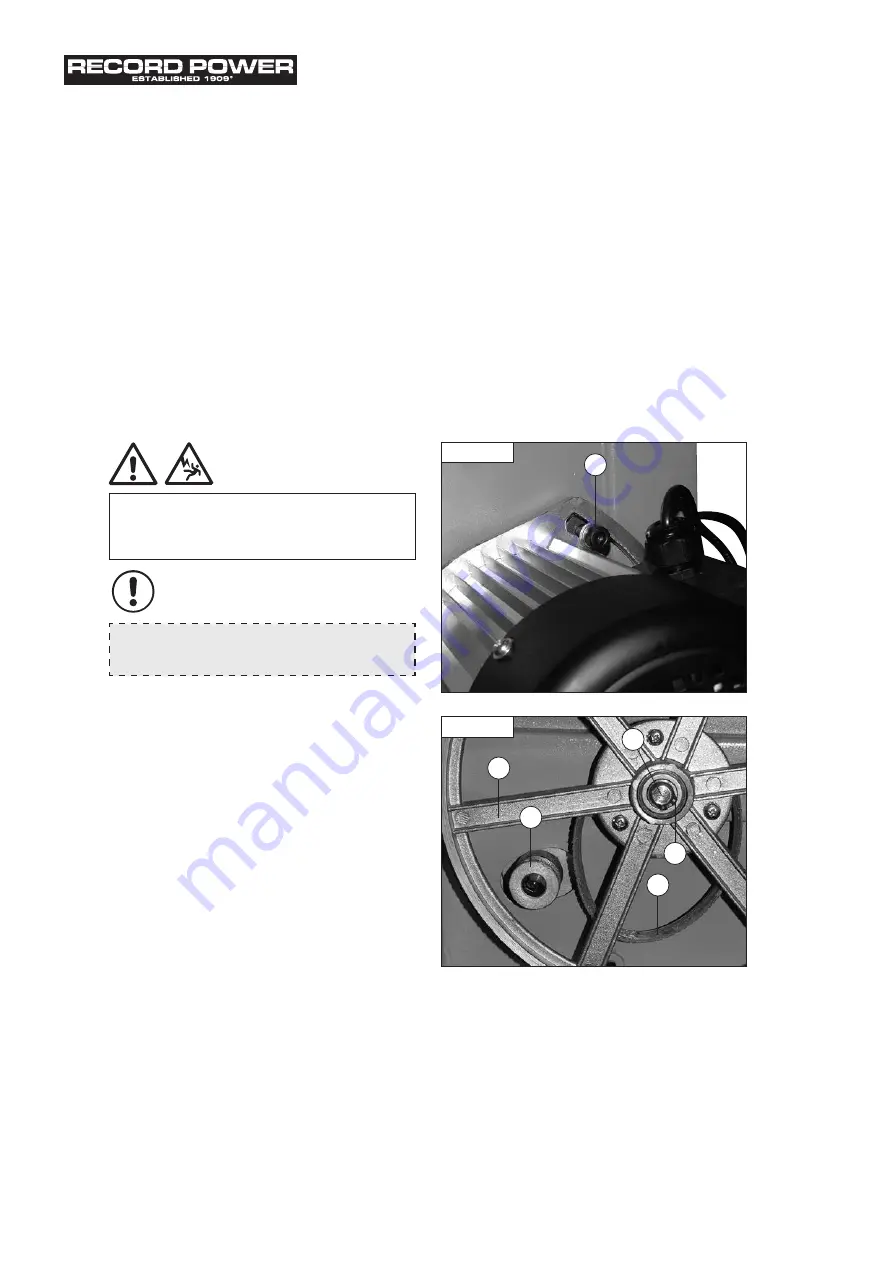

1. To replace the drive belt slacken the tension on the belt

by loosening the motor pivot screw on the back of the

machine, lifting the motor and re-tightening the

screw (Fig. 14.3, A).

2. Ease the drive belt (Fig. 14.4, B) off the motor

pulley (Fig. 14.4, C).

3. Ensuring that there isn't a blade fitted now remove the

lower bandwheel (Fig. 14.4, D) by releasing the circlip

(Fig. 14.4, E) from the hub (Fig. 14.4, F).

4. Remove the old belt and fit the new one.

5. Once the drive belt is in place re-fit the

lower bandwheel.

6. Now tension the drive belt by loosening the motor pivot

screw and lowering the motor until adequate tension is

applied. Re-tighten the motor pivot screw. The correct

tension is achieved when there is approximately 6 mm

of movement of the belt when reasonable pressure is

applied by hand.

CAUTION!

Before carrying out any adjustments or

maintenance ensure that the machine is isolated and

disconnected from the electricity supply.

Note:

Circlip pliers are required for this procedure.

Replacing the Drive Belt

Fig. 14.3

A

B

C

D

F

E

Fig. 14.4

i

Kg

i

Kg

i

Kg

Summary of Contents for BS10

Page 32: ...32 15 Parts list and Diagrams Cont ...

Page 33: ...33 15 Parts list and Diagrams Cont ...

Page 35: ...35 ...