28

14. Maintenance - Cont.

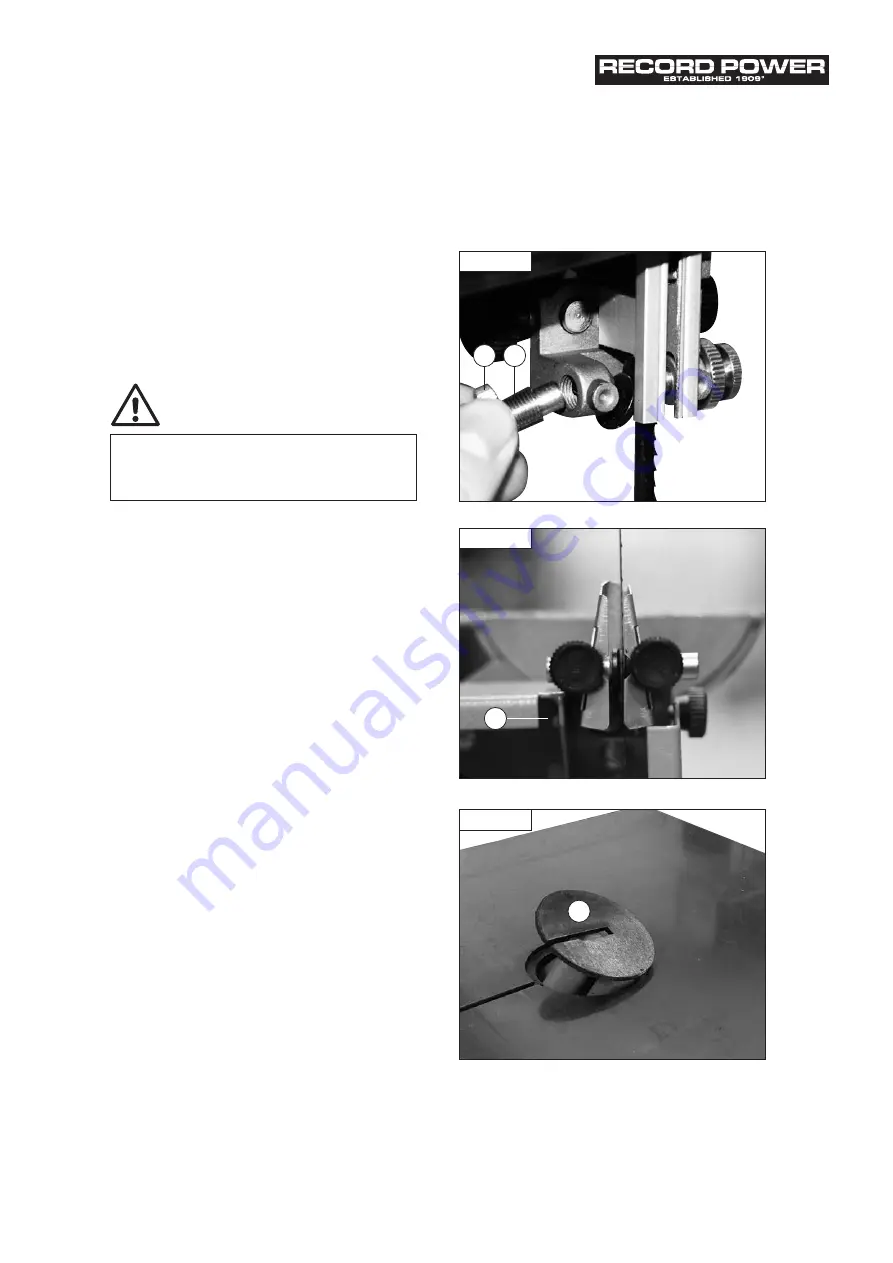

The Blade Guide System

In general usage it is advisable to carefully apply silicone

spray to the blade guides to ensure free movement of the

rollers, do not use oil or grease for lubrication as this will

attract dust and cause the rollers to jam. The blade guide

system is a consumable item and depending on usage will

wear and may need replacing.

CAUTION!

It is advisable that the blade has been

removed from the machine before replacing the blade

guide components.

When replacing components on the upper guide assembly,

loosen the guide carrier locking knob (Fig. 14.5, A) and remove

the whole assembly.

When replacing components on the lower guide assembly,

remove the pivot bolt (Fig 14.6, A) and then remove the

whole assembly.

To change the side roller guides (Fig. 14.5), unscrew the

locking ring (Fig. 14.5, A) and unscrew the roller support shaft

(Fig. 14.5, B). As the support shaft is removed from the guide

support casting, the guide roller will be extracted from the

shaft. Replace the roller and re-assemble.

For full details on adjustment of the blade guides please see

the bandsaw blade setup section of the manual.

The Table Insert

The table insert on a bandsaw is a consumable item

(Fig. 14.7 A) and will therefore need replacing periodically.

This procedure should be carried out with the bandsaw blade

removed. To replace the table insert simply push the old insert

out from underneath the table and fit the new one

into position.

The Bandwheel Tyres

The bandwheels on this machine have rubber tyres fitted to

the outer rim of the wheel (Fig. 14.8, B) to protect the set of

the blade when in use, also to provide drive and to stop the

blade slipping. As part of your regular service schedule inspect

the tyres for wear and damage and replace if necessary.

Again this is a consumable part of the bandsaw and will need

replacing periodically depending on usage. First remove the

blade from the bandsaw, then remove the bandwheel. Gently

ease the existing tyre from the rim taking care not to damage

the bandwheel. To fit the new tyre it is a good idea to heat the

tyre first in hot water, this softens the rubber up and makes

it easier to stretch it over the bandwheel. The tyres before

stretching are much smaller than the bandwheel and a good

deal of stretching is required to make them fit. It is advisable

to get help from a second person who can insert the wheel

into the tyre while it is fully stretched.

Fig. 14.5

A

B

i

Kg

A

Fig. 14.7

Fig. 14.6

A

Summary of Contents for BS10

Page 32: ...32 15 Parts list and Diagrams Cont ...

Page 33: ...33 15 Parts list and Diagrams Cont ...

Page 35: ...35 ...