12

10. Dust Extraction

The Importance Of Dust Extraction

Before the machine is started, ensure that adequate dust extraction provi-

sions have been installed. Dust extraction is extremely important not only for

health and safety but also for the correct upkeep of the machine. Saw dust

can cause the machine not to operate properly or even fail completely. By

keeping the machine free of large amounts of waste the performance will be

optimised.

If a large amounts of MDF or toxic woods are to be cut we recommend that

there is a good ventilation system in place and that in addition to proper

extraction a mask or respirator be worn as minimum protection.

Record Power Extractors

Record Power offer a range of high quality dust extractors, we offer both

drum and bag type extractors which filter down 0.5 micron providing

protection from harmful fine dusts. All Record Power dust extractors & chip

collectors have 100 mm inlets and hoses.

DX1000 High Filtration Dust Extractor

Drum type extractor, 45 litre capacity, single 1 kW motor, suitable for inter-

mittent use ie must be switched off for 20 minutes every hour.

0.5 micron filtration

RSDE1 High Filtration Dust Extractor

Drum type extractor, 45 litre capacity, single 1 kW motor, suitable for inter-

mittent use ie must be switched off for 20 minutes every hour.

0.5 micron filtration

RSDE2 High Filtration Dust Extractor

Drum type extractor, 50 litre capacity, single 1 kW motor, suitable for inter-

mittent use ie must be switched off for 20 minutes every hour.

0.5 micron filtration

RSDE/2A High Filtration Dust Extractor

with Auto Switching

Drum type extractor, 50 litre capacity, single 1 kW motor, auto switching

allows the machine to be turned on and off as machines and power tools

are operated. Suitable for intermittent use ie must be switched off for 20

minutes every hour. Maximum auto switch capacity tools up to 1.1 kW.

0.5 micron filtration

DX4000 High Filtration Dust Extractor

Drum type extractor, 80 litre capacity, Twin 1 kW motor, suitable for heavy

usage ie if one motor is switched off for 20 minutes then the other can be

used thus enabling continuous usage. Or both motors can be used simul-

taneously giving maximum suction but in this mode the extractor must be

switched off for 20 minutes every hour.

0.5 micron filtration

DX5000 High Filtration Dust Extractor

Bag type extractor, 200 litre capacity, Twin 1 kW motor, suitable for heavy us-

age ie if one motor is switched off for 20 minutes then the other can be used

thus enabling continuous usage. Or both motors can be used simultaneously

giving maximum suction but in this mode the extractor must be switched off

for 20 minutes every hour.

0.5 micron filtration

CX2000 Compact Chip Extractor

Medium capacity chip collector, with a powerful 0.56 kW induction motor.

An extremely smooth running unit suitable for continuous usage. Very quiet

impeller system extracts dust and chippings.

CX2600 Chip Collector

Large capacity chip collector, with a powerful 0.37 kW induction motor.

An extremely smooth running unit suitable for continuous usage. Very quiet

impeller system extracts dust and chippings.

Suitable for chip collection or finer dust using the optional filter

cartridge

CX3000 Chip Collector

Larger capacity chip collector, with a more powerful 0.75 kW induction mo-

tor and heavy duty construction. An extremely smooth running unit suitable

for continuous usage. Very quiet impeller system extracts dust and chippings.

Suitable for chip collection or finer dust using the optional filter

cartridge

Air Cleaners

It is strongly advised to also use an air cleaner to remove the fine airborne

dust present in the workshop which cannot be removed using machine

extraction. Record Power offer a range of air cleaners suitable for all home

workshops. Please contact your preferred stockist or

visit www.recordpower.info.

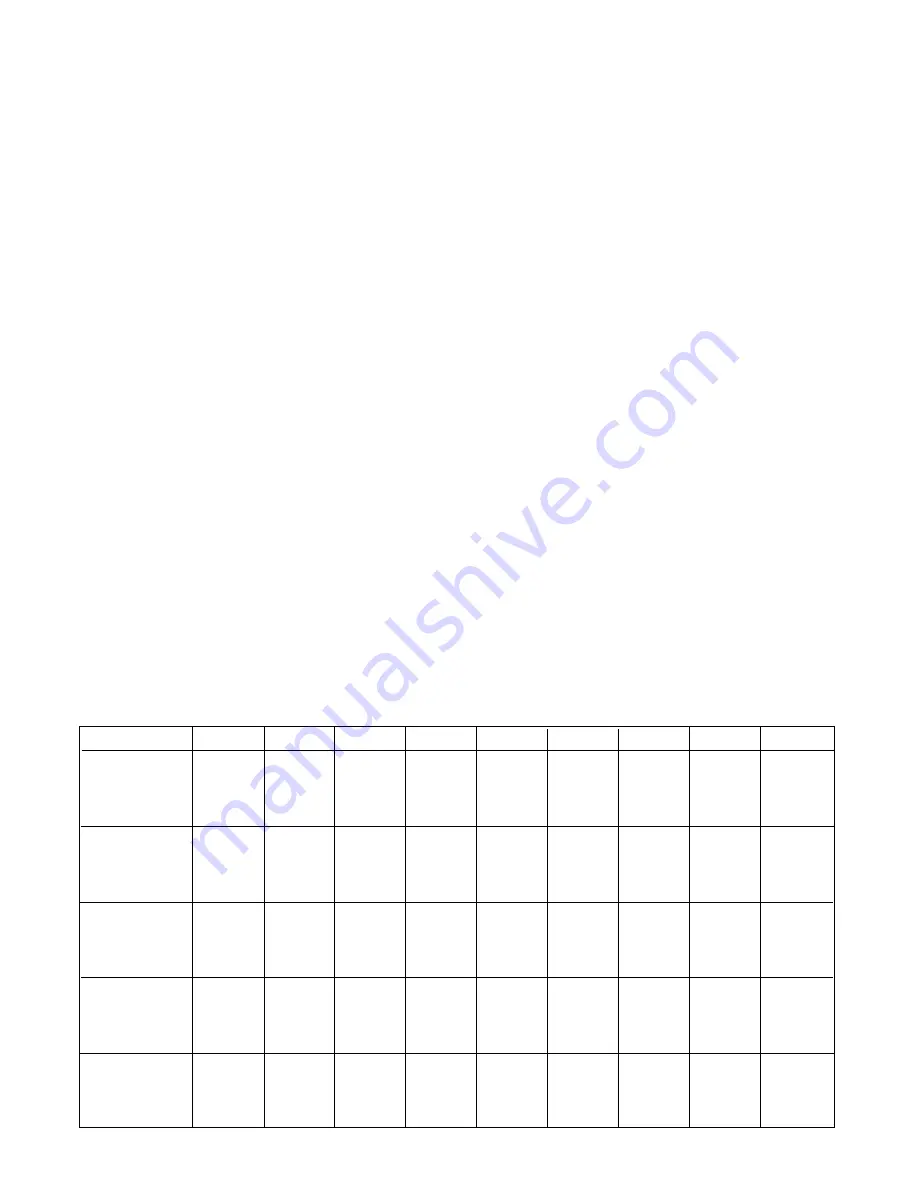

DX1000 RSDE1

RSDE2

RSDE/2A DX4000 DX5000 CX2000 CX2600 CX3000

Bandsaws

Circular saws

Sanders

Intermittent usage

Bandsaws

Circular saws

Sanders

Heavy usage

Planer Thicknessers

Spindle Moulders

Universals

Intermittent usage

Planer Thicknessers

Spindle Moulders

Universals

Heavy usage

Dust Extraction

System

Intermittent usage

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Recommended

3

Can be used

3

Can be used

3

Can be used