19

6. Maintenance

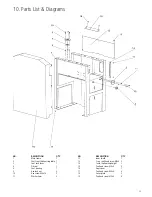

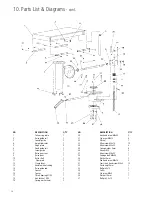

Fig. 6.4

Fig. 6.5

Fig. 6.6

C

B

A

Fig. 6.7

A

The cutter block in this machine is designed to hold three blades.

Never attempt to use the machine if any of the blades are

missing or damage. All blades used must conform to BS EN 847-1.

Changing the Planer Blades

Check the height of the Blade

The blades should be periodically replaced or adjusted. Adjustments should

be as precise as possible with tolerances within 1- 1.1mm to prolong the

sharpness of the blades edges.

Improperly adjusted Blades can unbalance the cutterblock and shorten

bearing life, as well as produce substandard thicknessing or planing results.

The planer blades fitted to this machines are made from high speed steel

and can be reshaped periodically to maintain the cutting edge and optimise

performance of the machine. The process of resharpening blades will

remove a small amount of material from the blade's edge and therefore

will reduce the overall width of the blade. Never attempt to use blades that

have been reduced by more than 25% of their original width. Always ensure

that the blade can be held securely by the blade holder. Replace deffective

blades immediately.

Caution: Before carrying out any adjustments or maintenance

ensure that the machine is isolated and disconnected from the

electricity supply.

1. Remove the cutter-block guard to expose the top of the cutter-block.

2. Carefully turn the cutter-block until the first blade is at top dead centre.

3. Using the cutter-block gauge check the blade height.

The gauge should sit solidly with the pads resting on the cutter-block. If the

knife is adjusted properly, the knife is barely touching the middle slot of

cutterblock gauge. If the knife does not touch the middle slot, or if the knife

causes the pads of gauge to not sit flush on the cutter-block, the knives

need to be adjusted. The Blades should protrude from the cutter block by a

maximum of 1.1mm.

Changing the blades

Caution: Before carrying out any adjustments or maintenance

ensure that the machine is isolated and disconnected from the

electricity supply.

1. Remove the cutter-block guard to expose the top of the cutter-block.

2. Carefully turn the cutter-block until the first blade is at top dead centre.

3. Release all blade holder screws (A -

Fig. 6.5

) of each blade, by screwing

them into the blade holder.

4. Remove the blade holder (B -

Fig. 6.5

) and planer blade (C -

Fig. 6.5

)

one at a time.

5. Repeat this process with all blades.

6. Clean the planer blades, blade holders and planer cutter block of traces

of resin as thoroughly as possible.

7. Reinstall the planer blades and blade holders, tighten the blade holder

screws lightly at first.

8. Check the height of blade (see “Check the height of blade”).

9. Turn the jack screw to adjust the height of knife, (

Fig. 6.6

)

10. Finally tighten all blade holder screws, (A -

Fig. 6.5

) by unscrewing

them from the blade holder.

Drive belts

Over time, the drive belt tension may loosen. In this case, the belt must

either be tightened or replaced.

Check the belt monthly for cracks or lateral tears.

Replace the belt if necessary.

Loosen motor mounting bolts A (

Fig 6.7

).

Use the weight of the motor to tension the drive belt. When the correct

tension is applied, tighten the motor mounting bolts A, (

Fig 6.7

).

i

Kg

i

Kg

i

Kg

i

Kg

i

Kg

Summary of Contents for PT107

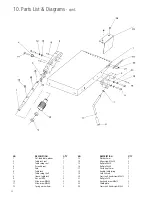

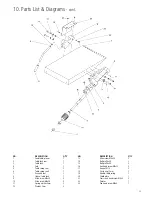

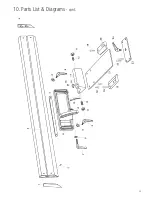

Page 29: ...29 10 Parts List Diagrams cont ...

Page 33: ...33 ...