16

Centre jacking screw

5. Machine Set Up

- cont.

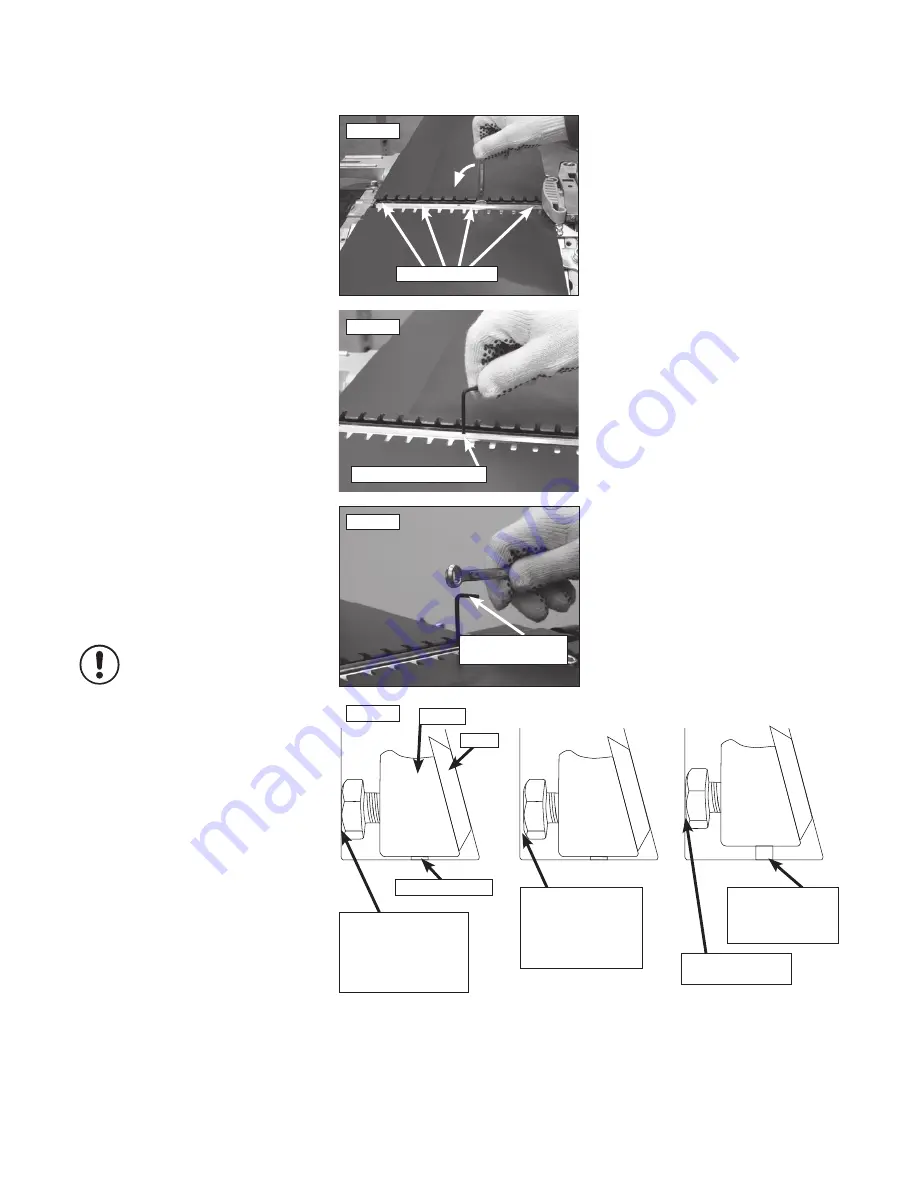

5.3 How to adjust Planer Knives

The wedge and knives are now ready to be set.

Turn the four locking nuts anti-clockwise

Fig 5.7

and tighten enough to hold the knife, but not so

hard that it cannot move. The principle is simply:

To raise the height of the knife tighten

the jacking screw, to lower slacken off

the jacking screw.

Setting planer knives is absolutely crucial to

accurate results, incorrectly set knives result in

a machine that either won’t plane at all, planes

tapers, or takes scoops (snipe) out of the end of

the work. if the blades are set too low the wood

will foul on the edge of the outfeed table, or

start to cut and then taper off. If the blades are

too high it will plane adequately but then take a

scoop (snipe) out at the end.

Listed below are a few hints to bear in

mind when setting the knives.

• The knives are set to the outfeed table, the

infeed table should be lowered out of the way.

• Adjust the centre jacking screw first and

tighten the two middle locking nuts.

Fig 5.8.

Now adjust either side to match the centre. By

making the adjustments in this order it should

remedy any slight distortion which is sometimes

present in planer knives if they have been held

by magnets when being ground.

• When tightening the jacking screws do so

very delicately, even a tiny fraction of a turn can

make a big difference as the jacking points are

very sensitive.

• When slackening the jacking screws it may be

necessary to tap the top of the hex key to get

this point to seat and lower the knife

Fig 5.9

• If the jacking screw becomes difficult to turn

when raising the knife it is because the space

allowed by the locking nut has been adjusted

out

Fig 5.10

, simply turn the relevant locking

nut in a little so the wedge has a little more

space to slide into.

• Whether adjusting the locking nuts or jacking

screws, do so in tiny increments. It is easier to

set the knives with the locking nuts being as

tight as possible whilst still allowing movement.

In general the procedure is:

1. Tighten jacking screw a fraction

2. Slightly back off locking nut.

3. Tighten jacking screw a little more.

4. Check setting.

5. Repeat until setting has been

achieved.

4 x locking nuts

Fig.5.7

Fig.5.8

Fig.5.9

Tap the top of the

hex key

Fig.5.10

Locking nut against

cutter block. Note; if

the jacking screw is

tightened there is no

space for the wedge

to slide.

Locking nut wound

in slightly, leaving

gap for wedge to

slide into when

jacking screw is

tightened

Locking nut now

tight again

Jacking screw

tightened sliding

wedge & knife

upwards

Knife

Jacking screw

Wedge

i

Kg

Summary of Contents for PT260

Page 28: ...28 11 Parts Diagrams Stand Wheel Kit ...

Page 29: ...29 11 Parts Diagrams cont ...

Page 30: ...30 11 Parts Diagrams cont ...

Page 34: ...34 ...

Page 35: ...35 ...