20

6. Operation & Planer Thicknesser Practice

- cont.

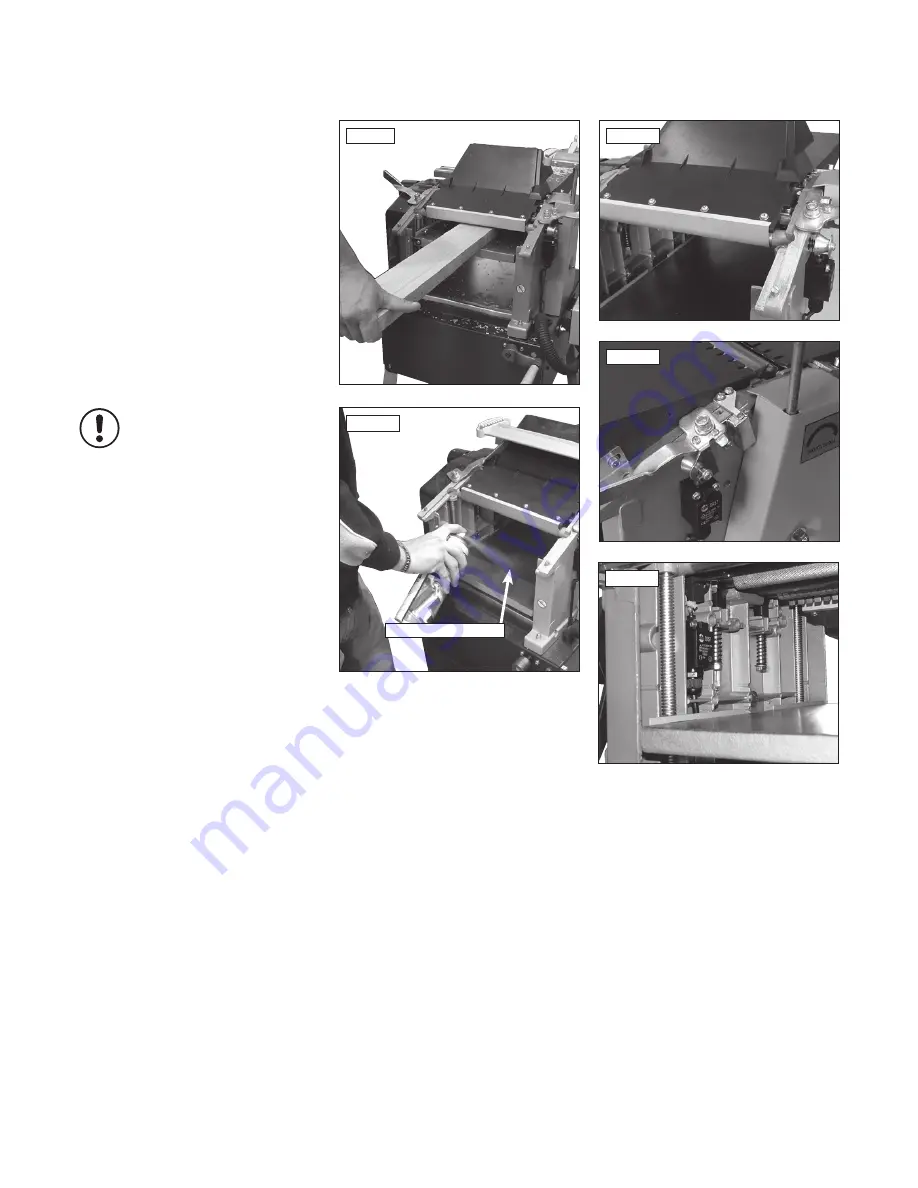

Start machine and place workpiece with planned

side facing down on to thicknessing bed and

slowly push forward until feed roller engages

Fig.6.8

.

IMPORTANT:

With wedge-shaped workpieces feed the thicker

end in first.

The timber will now feed through the machine

and should be removed as it travels through.

Wind the handle so the thicknessing bed is

raised 1mm on the scale and feed the timber

through again. Repeat this process until the

timber is sized as required. Although the

maximum depth of cut is 3mm, by taking off

1mm at a time the results will be much cleaner

and the machine will be under less strain.

The thicknessing bed should be

cleaned with white spirit and treated

regularly with a silicone based spray

such as Record Power CWA195. This will

enable the workpiece to move through

smoothly and cleanly, Fig.6.9.

6.7 Micro Switches

The purpose of the microswitch is to enhance

the safety of the machine by ensuring that the

cutterblock is inaccessible whilst the machine

is in operation. The PT260 is equipped with 3

safety micro switches.

1. In thicknesser mode, the extraction port

must be placed over the cutterblock, covering it

before the machine will start

Fig.6.10

.

2. When planing, the table lock handles must be

engaged. The micro switch registers that the lock

handle is positioned correctly and allows power

to run to the machine

Fig.6.11

.

3. Also when planing, the micro switch beneath

the cutterblock must register that the dust

extraction port is in place before the machine

will start

Fig.6.12

.

Fig.6.8

Fig.6.9

Thicknessing Bed

Fig.6.10

Fig.6.11

Fig.6.12

i

Kg

Restarting

In the Event of a Blockage or if the Machine Stalls

If the machine stalls due to the work piece becoming trapped in the cutter

block,

switch it off immediately by pressing the emergency stop button (Red button

marked ‘O’) and wait for the machine to come to a complete stop before

proceeding further.

If the work piece is trapped between the cutter block and thicknessing table,

it may be necessary to lower the thicknessing table in order to free

the blockage.

To re-start the machine, press the green button marked ‘I’ on the switch.

In the Event of a Power Failure

The machine is fitted with a no volt release (NVR) switch to protect the user

against automatic starting of the machine when power is restored

after a power failure.

In the event of a power failure, first locate and rectify the source of the

failure. If the fault is within the power circuit of the workshop, there may be

an underlying cause (circuit overload etc.) that should be investigated by a

qualified electrician, before attempting to restore the power source.

If a cutting operation was taking place when the power supply was

interrupted, then it may be necessary to free the work piece from the cutter

before attempting to re-start the machine.

Once the power is restored, the machine can be re-started by pressing the

'on' switch.

Summary of Contents for PT260

Page 28: ...28 11 Parts Diagrams Stand Wheel Kit ...

Page 29: ...29 11 Parts Diagrams cont ...

Page 30: ...30 11 Parts Diagrams cont ...

Page 34: ...34 ...

Page 35: ...35 ...