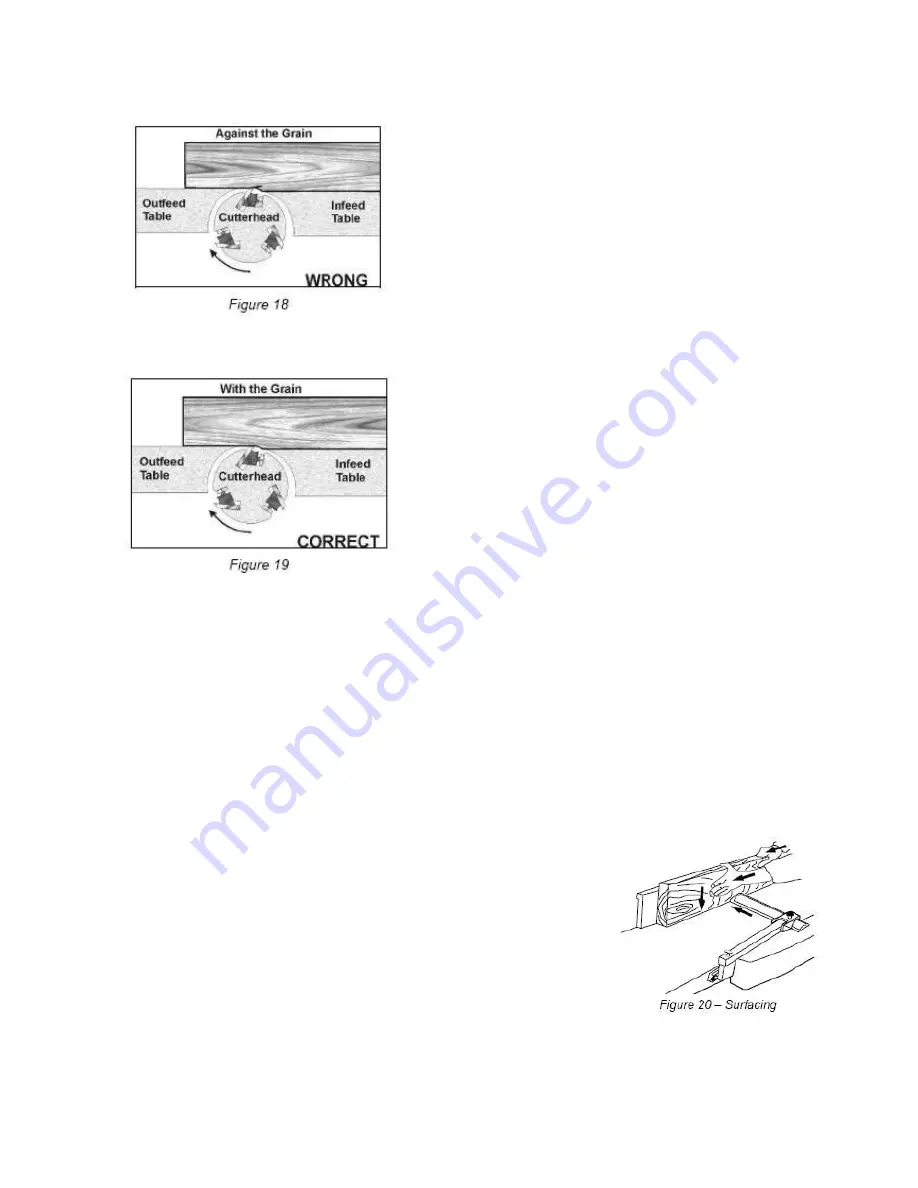

Direction of Grain

Avoid feeding work into the jointer against the grain (Figure 18).

This may result in chipped and splintered edges. Feed with the grain to obtain a smooth surface, as

shown in Figure 19.

Jointing

Jointing (or edging) is the process of creating a finished, flat edge surface that is suitable for

joinery or finishing (Figure 20). It is also a necessary step prior to ripping stock to width on a table

saw.

Never edge a board that is less than 3 inches wide, less than 1/4 inch thick, or 12

inches long, without using a push block.

When edging wood wider than 3 inches lap the fingers over the top of the wood,

extending them back over the fence such that they will act as a stop for the hands in the event of

a kickback.

Position the fence (move forward) to expose only the amount of cutterhead required.

When workpiece is twice the length of the jointer infeed or outfeed table use an infeed or outfeed

support.

To edge:

1. Make sure the fence is set to 90°. Double

check it with a square.

2. Inspect stock for soundness and grain

direction (refer to Direction of Grain on previous page).

3. If the board is bowed (curved), place the concave edge down on

the infeed table.

4. Set the infeed table for a cut of approximately 1.5mm.

5. Hold the stock firmly against the fence and table, feed the stock

slowly and evenly over the cutterhead.

Summary of Contents for PT260

Page 25: ...Troubleshooting Performance Troubleshooting Jointer ...

Page 26: ...Performance Troubleshooting Planer ...

Page 27: ...Mechanical Troubleshooting Planer Jointer ...

Page 28: ...PT 260 Cutter Block Guard and Outfeed Assembly ...

Page 30: ...PT 260 Cutter Block assembly ...

Page 32: ...PT 260 Base Assembly ...

Page 34: ...PT 260 Infeed Table Assembly ...

Page 36: ...PT 260 Drive and Motor Assembly ...

Page 38: ...PT 260 Thickness Table Assembly ...

Page 40: ...PT 260 Working Fence Assembly ...