19

10.1

WG250/A

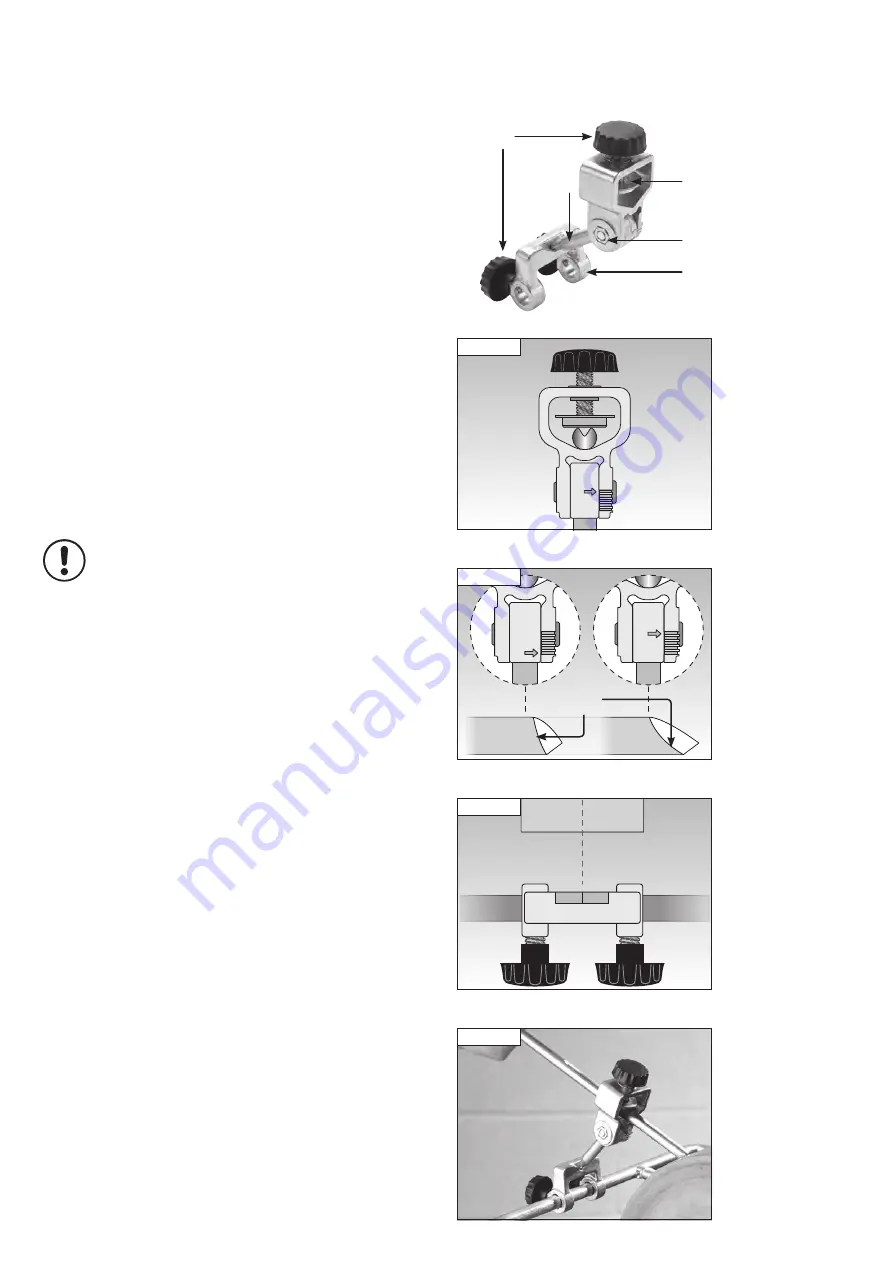

Gouge Jig

Use to sharpen:

• Bowl gouges

• Spindle gouges

• V-tools

The gouge jig attaches to the support arm of the wet stone sharpener.

A

Knob screw

B

Tool holder

C

Shaft

D

Support arm mount

E

Elbow joint

Using the Gouge Jig

Mount the tool in the tool holder with the required length of blade

protruding to allow enough clearance between the jig and stone when in

use. The protrusion varies depending on the tool being sharpened and a

good rule of thumb is at least 50 mm (2”) is sufficient for many tools. See

Fig 10.1.1

.

Adjust the angle of the shaft relative to the tool holder using the hex head

socket screw located in the elbow joint. For shorter side bevels, such as

those found on bowl gouges, lock the shaft in the uppermost position and

for longer bevels, as on spindle gouges, lock the shaft in lower positions.

See

Fig 10.1.2

.

Please note this should be done before setting the position of

the tool to the correct bevel angle as any adjustments of the

shaft after this will change the bevel angle that will be applied

to the stone.

Place the support arm in the side position.

Secure the support arm mount to the support arm and align it centrally to

the cutting face of the sharpening wheel. See

Fig 10.1.3

.

With the tool secured in the tool holder, place the shaft in the recess of the

support arm mount as shown in

Fig 10.1.4

.

A

C

B

E

D

Fig 10.1.1

Fig 10.1.3

Fig 10.1.4

Fig 10.1.2

Bevel

angle

i

Kg

Summary of Contents for WG200

Page 39: ...39 ...