A-1

INSTALLATION

MEGA FORCE

®

140i MP

®

INSTALLATION

TECHNICAL SPECIFICATIONS -

*Max wire feed speed achieved with a spool gun

Thermal tests have been performed at ambient temperature. The duty

cycle (duty factor) at 40°C has been determined by simulation.

select sUitable location

Place the machine on a secure, level surface or recommended

undercarriage. The machine may topple over if this procedure is

not followed. To minimize over heating, locate the welder in a dry

location where there is free circulation of clean air. Do not place

on combustible surfaces.

The machine is capable of higher duty cycles at lower output

currents or higher amperages at lower duty cycles. An overview

of the machine’s input and output capabilities are available on the

rating plate located on the back of the machine.

location anD MoUntinG

The welding machine will operate in harsh environments. Even so,

it is important that preventative measures are followed in order to

assure long life, reliability, and safe operation.

•

The welding machine must be located in an area with

circulation of clean air such that air moves in the back of the

machine and out the front louvers.

•

Dirt and dust that can be drawn into the welding machine

should be kept to a minimum. Failure to observe these

precautions can result in excessive operating temperatures,

nuisance thermal trips and potential failures.

environMental ratinG

The welding power source carries an IP21S rating. It may be used

in normal industrial and commercial environments. Avoid using in

areas where water / rain is present.

Read and follow the ‘Electric Shock Warnings’ in the safety section

if welding must be performed under electrically hazardous

conditions such as welding in wet areas or water on the work

piece.

enGine Driven Generator

The machine is designed to operate on engine driven generators as

long as the auxiliary can supply adequate voltage, frequency and

power as indicated in the “Technical Specification” Installation

Section of this manual. The auxiliary supply of the generator must

also meet the following conditions:

Frequency:

60 Hz

RMS voltage of the AC waveform:

90-140 V; Out of this range will

trigger undervoltage and overvoltage protections.

Generator Minimum

6 kW

It is important to check these conditions because many engine driven

generators produce high voltage spikes. Operation of this machine

with engine driven generators not conforming to these conditions is

not recommend and may damage the machine and is also NOT

covered by warranty.

INPUT VOLTAGE AND CURRENT

Duty Cycle

(Output)

Input Voltage Input Amperes

Max

Idle Amps

60% FOR MIG

120 V~

20 A

.7A

RECOMMENDED INPUT WIRE AND FUSE SIZES

Voltage/Phase/

Frequency

Input Amperes

Effective

Fuse (Super Lag) or

Breaker Size

120/1/60Hz

15 A

20 A

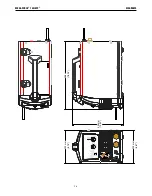

PHYSICAL DIMENSIONS

Height

Width

Depth

Weight

13.6”

(345mm)

8.9”

(224mm)

18.1”

(460mm)

34.5 lbs.

(15.6 kg)

WELDING PROCESSES

Process

Electrode Diameter

Range

Output Range

(Amperes)

Wire Feed

Speed Range

MIG

.025-.035”

( 0.6-0.9mm)

20-140

40-500* IPM

FCAW

.030-.035”

(0.8-0.9mm)

20-140

40-400 IPM

TIG

.040, 1/16, 3/32”

(1.0, 1.6MM, 2.4mm)

10-120

NA

STICK

Up to 3/32”

(2.4mm)

25-90

NA

TEMPERATURE RANGES

Operating

Temperature

-4°F TO 104°F (-20°C TO 40°C)

Storage

Temperature

-40°F TO 185°F (-40°C TO 85°C)

WELDING PROCESSES

Process

Duty Cycle

Amperage

Voltage

MIG & FCAW

60%

95 AMPS

18.75 VOLTS

TIG

60%

115 AMPS

14.6 VOLTS

STICK

60%

80 AMPS

23.2 VOLTS

REGULATORY REQUIREMENTS

Market

Conformity Mark

Standard

MÉXICO

NOM

NMX-J-038-1

ANSE 2016