8

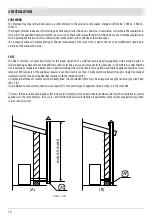

2-INSTALLATION

The instructions in this chapter refer explicitly to the Italian installation regulation UNI 10683. In any case,

always observe the regulations in force in the country of installation.

PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust which is produced during the working of natural dried wood. The

compactness of the material is guaranteed by the lignin contained in the wood itself and allows pellets to be produced without glue or

binders.

The market offers different types of pellets with characteristics that vary according to the wood mixtures used. The most common diameter

on the market is 6 mm (although 8 mm diameter is available too) with a length, on average, of between 3 and 40 mm. A good quality

pellet has a density of between 600 and 750 or more kg/metres cubed and a moisture content that accounts for 5 to 8% of its weight.

Pellets have technical advantages besides being an ecological fuel, as the wood residue is used completely, thereby achieving cleaner

combustion than that of fossil fuels.

While good-quality wood has a calorific value of 4.4 kW/kg (15% moisture, after about 18 months of seasoning), whereas that of pellets

is around 4.9 kW/kg. To ensure good combustion, the pellets must be stored in a dry place and protected from dirt. Pellets are usually

supplied in 15 kg bags, therefore, storing them is very convenient.

Good quality pellets guarantee good combustion, thereby decreasing harmful emissions into the atmosphere.

The poorer the quality of the fuel, the more often the internal parts of the brazier and combustion chamber must

be cleaned.

The main quality certifications for pellets currently available on the European market guarantee that the fuel complies with class A1/A2

according to ISO 17225-2 (ex EN 14961). These certifications include, for example,

ENPlus

,

DINplus

,

Ö-Norm M7135,

and in particular,

guarantee the following characteristics:

•

calorific value: 4.6 ÷ 5.3 kWh/kg.

•

Water content: ≤ 10% of the weight.

•

Percentage of ash: max 1.2% of the weight (A1 less than 0.7%).

•

Diameter: 6±1/8±1 mm.

•

Length: 3÷40 mm.

•

Content: 100% untreated wood without the addition of binding agents (max 5% bark).

•

Packaging: in sacks made from ecologically compatible or biologically decomposing material.

The company strongly recommends using certified fuel for its products (ENplus, DINplus, Ö-Norm M7135).

Poor quality pellets or others that do not comply with the characteristics specified previously may compromise the

operation of your product and can therefore make the guarantee and product liability invalid.

BAG OF PELLETS 15 kg