3

1.0 i

nstalling

the

m

eter

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and neutral soap product.

Do NOT use solvents.

Continuous exposure to direct sunlight may accelerate the aging process of

the bezel. Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to

operate the keypad of the unit.

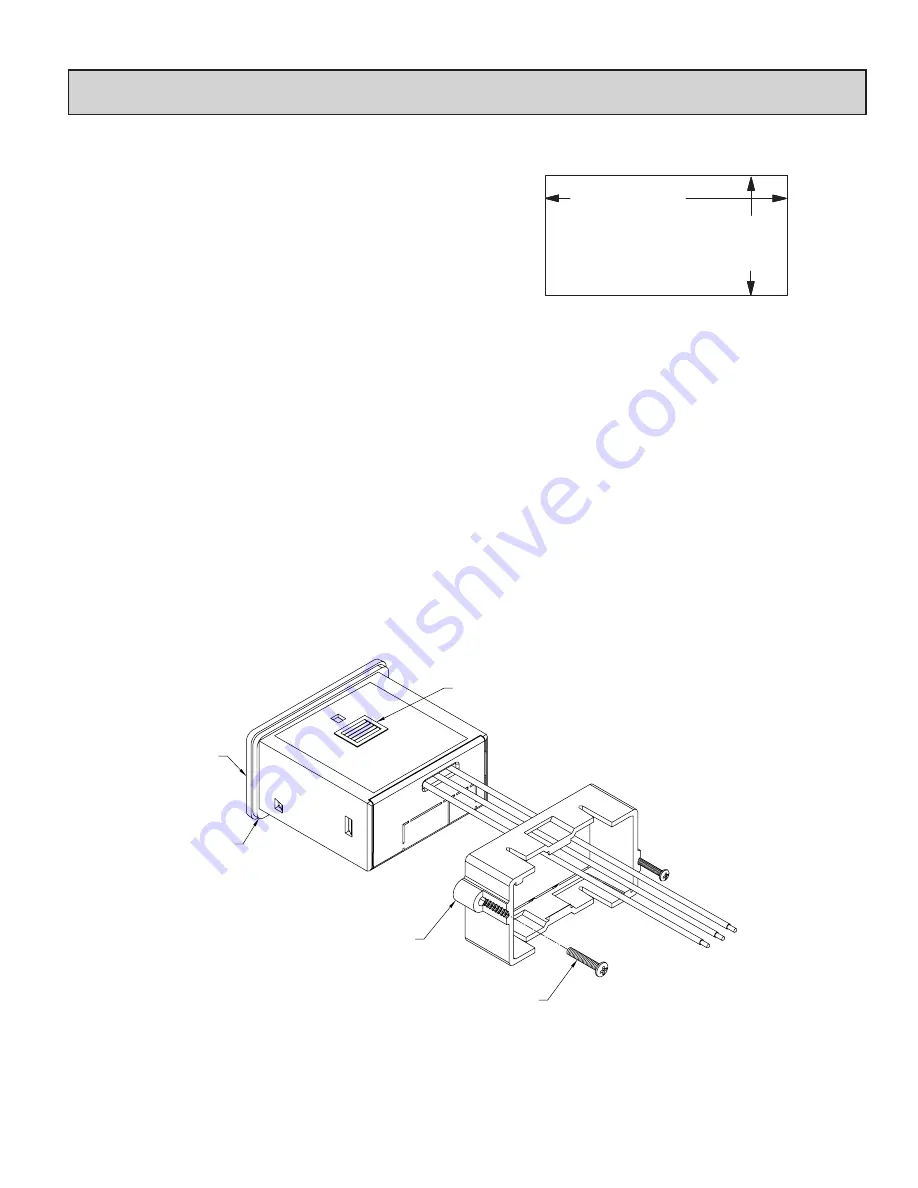

Installation

The CUB7 series of products meets NEMA 4X/IP65 requirements for

outdoor use, when properly installed. The units are intended to be mounted into

an enclosed panel. The viewing window and reset button are factory sealed for

a washdown environment. A sponge rubber gasket and mounting clip are

provided for installing the unit in the panel cut-out.

The following procedure assures proper installation:

1. Cut panel opening to specified dimensions. Remove burrs and clean around

panel opening.

2. Carefully remove and discard the center section of the gasket. Slide the panel

gasket over the rear of the unit to the back of the bezel. Insert the mounting

screws onto both sides of mounting clip. The tip of the screw should

NOT

project from the hole in the mounting clip.

3. Install the CUB7 unit through the panel cut-out until the front bezel flange

contacts the panel.

4. Slide the mounting clip over the rear of the unit until the clip is against the

back of the panel. The mounting clip has latching features which engage into

mating features on the CUB7 housing.

Note: It is necessary to hold the unit in place when sliding mounting clip into

position.

5. Alternately tighten each screw to ensure uniform gasket pressure. Visually

inspect the front panel gasket. The gasket should be compressed to about 75

to 80% of its original thickness. If not, gradually turn mounting screws to

further compress gasket.

6. If gasket is not adequately compressed and the mounting screws can no longer

be turned, loosen mounting screws, and check that mounting clip is latched

as close as possible to the panel.

7. Repeat from step #5 for tightening mounting screws.

Latching Feature

Bezel

Gasket

Mounting

Clip

Mounting

Screw

0.88

1.77

(22.2 )

(45 )

+0.024

-0.000

+0.6

-0.0

+0.012

-0.000

+0.3

-0.0