3

EMC INSTALLATION GUIDELINES

Although this unit is designed with a high degree of immunity to

ElectroMagnetic Interference (EMI), proper installation and wiring methods

must be followed to ensure compatibility in each application. The type of the

electrical noise, source or coupling method into the unit may be different for

various installations. In extremely high EMI environments, additional measures

may be needed. The unit becomes more immune to EMI with fewer I/O

connections. Cable length, routing and shield termination are very important

and can mean the difference between a successful installation or a troublesome

installation. Listed below are some EMC guidelines for successful installation

in an industrial environment.

1. Use shielded (screened) cables for all Signal and Control inputs. The shield

(screen) pigtail connection should be made as short as possible. The

connection point for the shield depends somewhat upon the application.

Listed below are the recommended methods of connecting the shield, in order

of their effectiveness.

a. Connect the shield only at the panel where the unit is mounted to earth

ground (protective earth).

b. Connect the shield to earth ground at both ends of the cable, usually when

the noise source frequency is above 1 MHz.

c. Connect the shield to common of the unit and leave the other end of the

shield unconnected and insulated from earth ground.

2. Never run Signal or Control cables in the same conduit or raceway with AC

power lines, conductors feeding motors, solenoids, SCR controls, and

heaters, etc. The cables should be run in metal conduit that is properly

grounded. This is especially useful in applications where cable runs are long

and portable two-way radios are used in close proximity or if the installation

is near a commercial radio transmitter.

3. Signal or Control cables within an enclosure should be routed as far away as

possible from contactors, control relays, transformers, and other noisy

components.

4. In extremely high EMI environments, the use of external EMI suppression

devices, such as ferrite suppression cores, is effective. Install them on Signal

and Control cables as close to the unit as possible. Loop the cable through the

core several times or use multiple cores on each cable for additional protection.

Install line filters on the power input cable to the unit to suppress power line

interference. Install them near the power entry point of the enclosure. The

following EMI suppression devices (or equivalent) are recommended:

Ferrite Suppression Cores for signal and control cables:

Fair-Rite # 0443167251 (RLC #FCOR0000)

TDK # ZCAT3035-1330A

Steward #28B2029-0A0

Line Filters for input power cables:

Schaffner # FN610-1/07 (RLC #LFIL0000)

Schaffner # FN670-1.8/07

Corcom #1VR3

Note:

Reference manufacturer’s instructions when installing a line filter.

5. Long cable runs are more susceptible to EMI pickup than short cable runs.

Therefore, keep cable runs as short as possible.

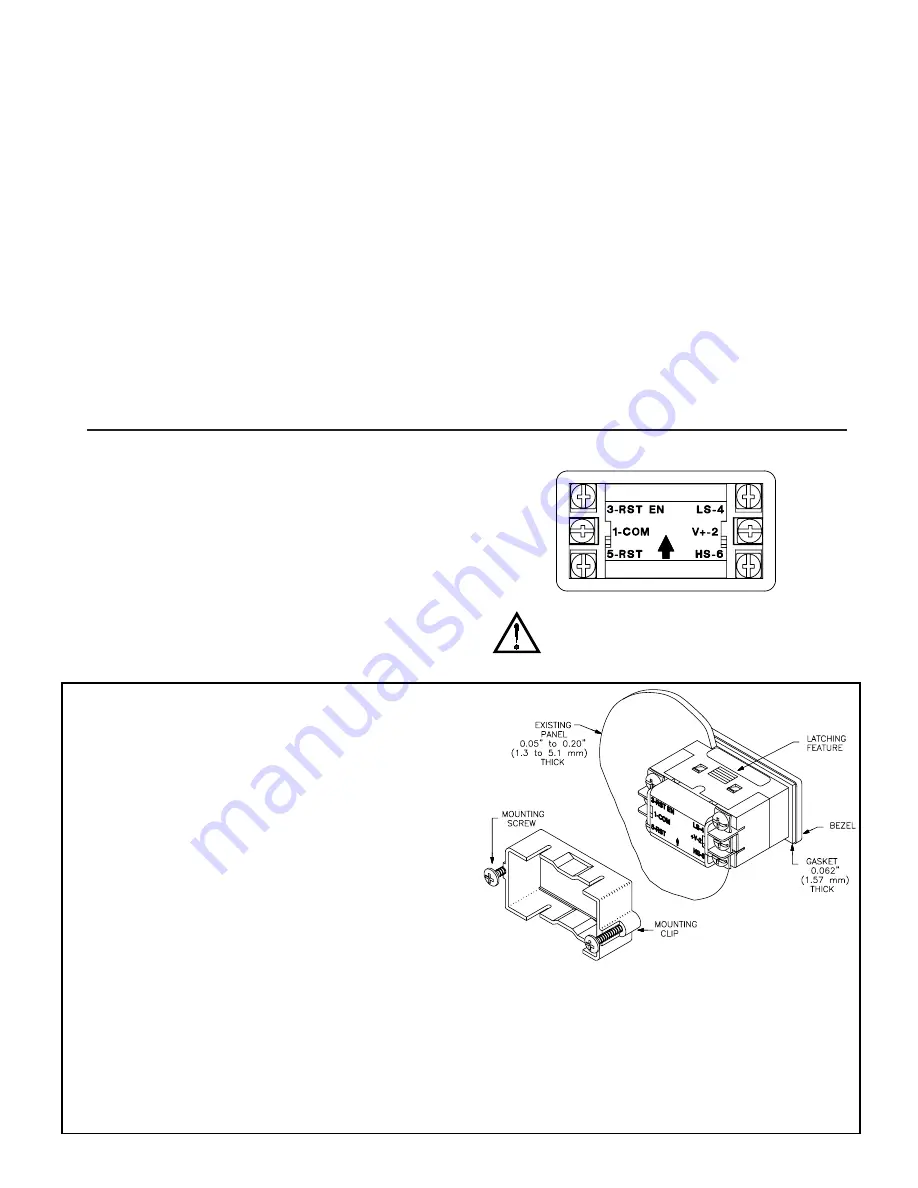

WIRING CONNECTIONS

The electrical connections are made via screw-clamp terminals located on

the back of the unit. All conductors should meet voltage and current ratings for

each terminal. Also cabling should conform to appropriate standards of good

installation, local codes and regulations. It is recommended that power supplied

to the unit (AC or DC) be protected by a fuse or circuit breaker. When wiring

the unit, use the battery cover to identify the wire position with the proper

function. Strip the wire, leaving approximately 1/4" bare wire exposed

(stranded wires should be tinned with solder). Insert the wire under the screw-

clamp and tighten down the screw until the wire is clamped in tightly. Each

terminal can accept up to two #14 AWG wires.

Backlight Wiring

Optional backlight versions of the CUB7 series require an external 9-28

VDC power supply. The external supply is connected between the V+ and

Common terminals.

WARNING:

Lithium battery may explode if incinerated. All

leads will be at the same line potential as the input leads.

INSTALLATION ENVIRONMENT

The unit should be installed in a location that does not exceed the maximum

operating temperature and provides good air circulation. Placing the unit near

devices that generate excessive heat should be avoided.

The bezel should be cleaned only with a soft cloth and neutral soap product.

Do NOT use solvents.

Continuous exposure to direct sunlight may accelerate the aging process of

the bezel.

Do not use tools of any kind (screwdrivers, pens, pencils, etc.) to operate

the keypad of the unit.

Installation

The CUB7 series of products meets NEMA 4X/IP65 requirements for

indoor use, when properly installed. The units are intended to be mounted into

an enclosed panel. The viewing window and reset button are factory sealed for

a washdown environment. A sponge rubber gasket and mounting clip are

provided for installing the unit in the panel cut-out.

The following procedure assures proper installation:

1. Cut panel opening to specified dimensions. Remove burrs and clean around

panel opening.

2. Carefully remove and discard the center section of the gasket. Slide the

panel gasket over the rear of the unit to the back of the bezel. Insert the

mounting screws onto both sides of mounting clip. Tip of screw should

NOT

project from hole in mounting clip.

3. Install CUB7 unit through the panel cut-out until front bezel flange contacts

the panel.

4. Slide the mounting clip over the rear of the unit until the clip is against the

back of the panel. The mounting clip has latching features which engage

into mating features on the CUB7 housing.

Note: It is necessary to hold the unit in place when sliding mounting clip

into position.

5. Alternately tighten each screw to ensure uniform gasket pressure.

Visually inspect the front panel gasket. The gasket should be compressed to

about 75 to 80% of its original thickness. If not, gradually turn mounting

screws to further compress gasket.

6. If gasket is not adequately compressed and the mounting screws can no

longer be turned, loosen mounting screws, and check that mounting clip is

latched as close as possible to the panel.

7. Repeat from step #5 for tightening mounting screws.