WIRING CONNECTIONS

There are certain considerations that should be observed when running the

count and control signal wires. A length of wire can act like an antenna and the

closer it is to a source of electrical noise, the more it becomes susceptible to that

noise. There are a few rules that should be followed when running these wires.

1. The CUB controller Common may be connected to machine ground (earth)

only at one point, preferably a single, direct connection between a known

good, earth ground and the Input Common Terminal.

2. Never run count and control signal leads in the same conduit or race ways

with conductors feeding motors, solenoids, SCR controls, inductive loads,

heaters, etc. Ideally, signal wires should be run by themselves in a separate

conduit.

3. Signal leads within electrical enclosures should be routed as far from

contactors, motor starters, control relays, transformers and their lead wires,

and other similar components as is possible.

4. When shielded wire is used, connect the shield to the common of the CUB

Controller, and leave the other end of the shield disconnected and insulated

from machine ground.

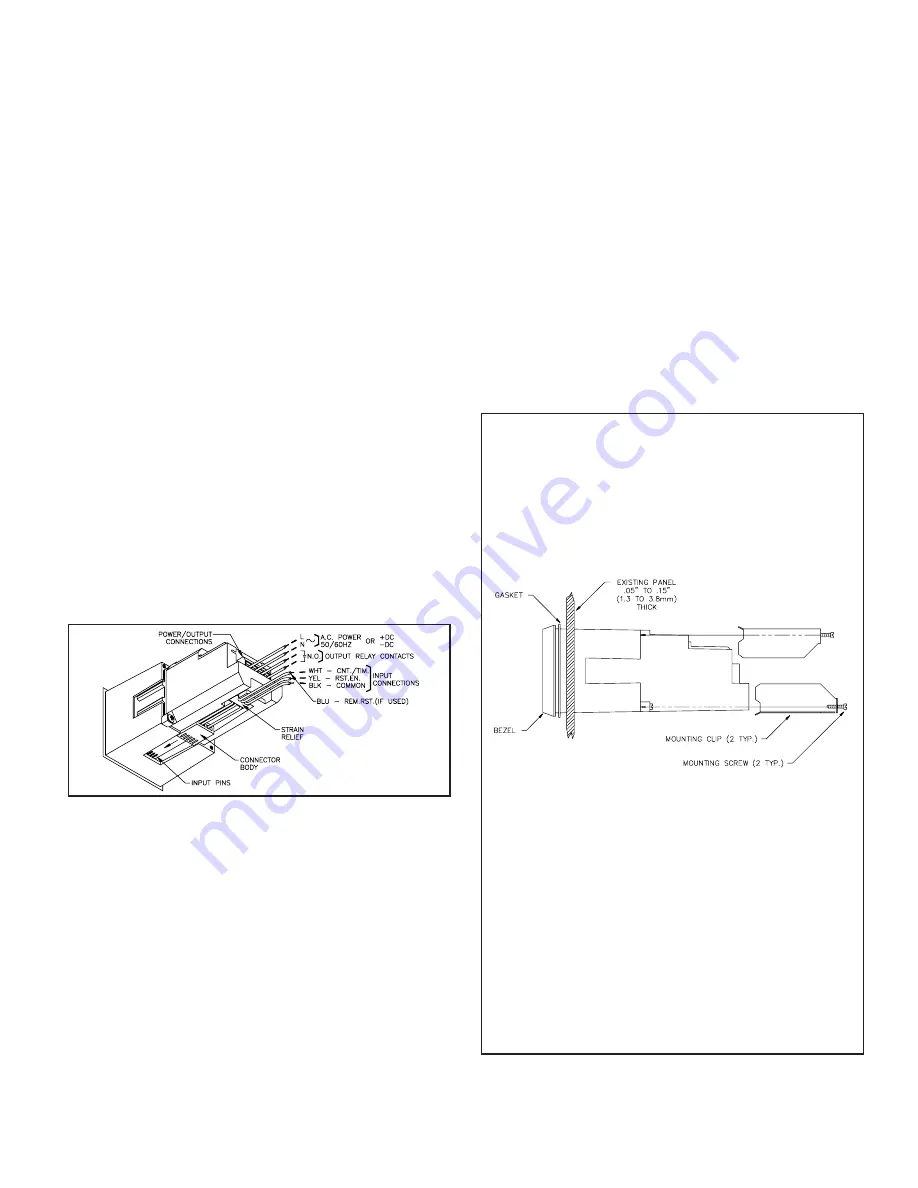

INPUT CONNECTIONS

The five position polarized connector with three wires installed is plugged

into the pins on the bottom of the unit. There is a separate blue wire supplied in

the hardware pack that can be installed into the connector. Each wire has a

different color and a specific function.

Common (Black wire)

- Other inputs are connected to common.

Reset Enable (Yellow wire)

- Enables the front panel reset button “R”

when connected to common.

Remote Reset (Blue wire)

- Performs a manual reset to the unit when

connected to common (Maintained reset).

Count Input (White wire)

- The counter increments or decrements, depending

on the mode selected, when connected to common.

The blue wire (if required) should be inserted between the white and yellow

wire before plugging the connector into the unit.

Slide the connector body into the groove on the bottom side of the CUB

Controller until it seats into the pins as shown in figure B. Loop the wires over

the first tab and then under the second tab for proper strain relief.

Note: For quick reference, input wire labeling is shown on the top of the rear

cover.

POWER & OUTPUT CONNECTIONS

The Power and Output electrical connections are made via screw-clamp

terminals located on the back of the unit. When wiring the unit, refer to the

stamping below the terminal block to identify the wire position with the proper

function. Strip the wire, leaving approximately 1/4" (6 mm) bare wire exposed

(stranded wires should be tinned with solder). Insert the wire into the screw-

clamp terminal and tighten the screw until the wire is clamped tightly. Each

terminal can accept up to one #14 AWG wire.

AC POWER WIRING VERSION

The AC power is connected to the two left terminals as viewed from the rear

of the unit. There are three A.C. version types available.

Note: Before applying power to the unit know the proper AC power voltage to

be connected. This can be done by comparing the part number on the side of

the unit to the ordering information.

CAUTION: On 10 to 28 VAC version units, the input common on the five

position connector (black wire) is not isolated internally from the AC power

connection. When making connections externally, be sure that input common

and AC power are isolated from each other, otherwise permanent damage to

the unit may occur.

To reduce the chance of noise spikes entering the AC line and affecting the

unit, the AC power should be relatively “clean” and within the specified 10%

variation limit. Connecting power from heavily loaded circuits or circuits that

also power loads that cycle on and off,

(contactors, relays, motors, etc.)

should

be avoided.

DC POWER WIRING VERSION

The DC power is connected to the two left terminals as viewed from the rear

of the unit. The DC plus (+) power is connected to the left-most terminal and

the DC common directly to the right of the plus terminal. The DC power source

must be capable of supplying the unit’s rated power of 1 watt. DC power

common is internally connected to the input connection common.

OUTPUT WIRING

The normally open (N.O.) output relay is connected to the two right-most

terminals as viewed from the rear of the unit. Care must be taken to ensure that

the maximum rating specifications are not exceeded, as this will shorten the life

of, or permanently damage the internal relay.

If more power handling capability or varied contact arrangement is required,

use an accessory relay.

DPDT RELAY P/N - RLY30000 (115 VAC-10 Amp)

Socket P/N SKT10000 is required for each relay purchased, see Ordering

Information.

INSTALLATION

Before installing the CUB Controller into the panel, the user should first

become familiar with the operation of the unit. Also, it may be desirable to

program the unit and set the appropriate DIP switches for the application.

When programming is complete, all parameters will be saved in nonvolatile

memory. The CUB Controller should be installed in a location that does

NOT exceed the maximum operating temperature.

The CUB Controller is designed with a high degree of electrical noise

immunity. However, installing the unit away from noise sources such as

relays, solenoids, motors, etc, should be considered.

The CUB Controller unit is designed to be panel-mounted with a gasket

to provide a water-tight seal. Two mounting clips are provided for easy

installation. Consideration should be given to the thickness of the panel. A

panel that is too thin may distort and not provide a water-tight seal,

therefore the recommended minimum panel thickness is 1/8" (3.2 mm). The

recommended clearance behind the panel for mounting clip installation is

2.77" (70.4 mm) H x 2.77" (70.4 mm) W.

After the panel cut-out is completed and deburred, carefully remove and

discard the center section of the panel gasket. Slide the panel gasket over

the unit from the rear, seating it against the lip of the case. Remove the two

mounting screws from the CUB Controller metal housing. These are at

diagonal corners to one another.

Note: Do NOT remove the screws that are holding the plastic insert into the

metal housing.

Insert the unit into the panel opening as depicted in the drawing. Place

the mounting clips over the two screw locations, insert the screws and

tighten evenly to apply uniform compression, thus providing a water-tight

seal.

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com

Courtesy of Steven Engineering, Inc.-230 Ryan Way, South San Francisco, CA 94080-6370-Main Office: (650) 588-9200-Outside Local Area: (800) 258-9200-www.stevenengineering.com