14 | Installation

3.2.3 WHAT YOU WILL NEED

TOOLS

In the following sections of this manual, guidance is given on the installation of the BCDC Core

which may require common automotive electrical tools such as:

• Screwdriver set

• Spanner set

• Socket set

• Pliers

• Side cutters

• Cable cutters

• Ratcheting or Hydraulic crimping tool

• Soldering Iron

CONSUMABLES

To mount, connect and manage wiring of the BCDC Core Battery Charger, installers use

a range of materials including:

• Cabling

• Cable connectors, lugs and terminals

• Fuses

• Electrical tape

• Heat Shrink

• Cable ties

• Conduit / Split tubing

• Wires

• Fasteners

Depending on your setup, additional fixings (nuts, bolts and self-tapping screws) and battery

post clamps may be required.

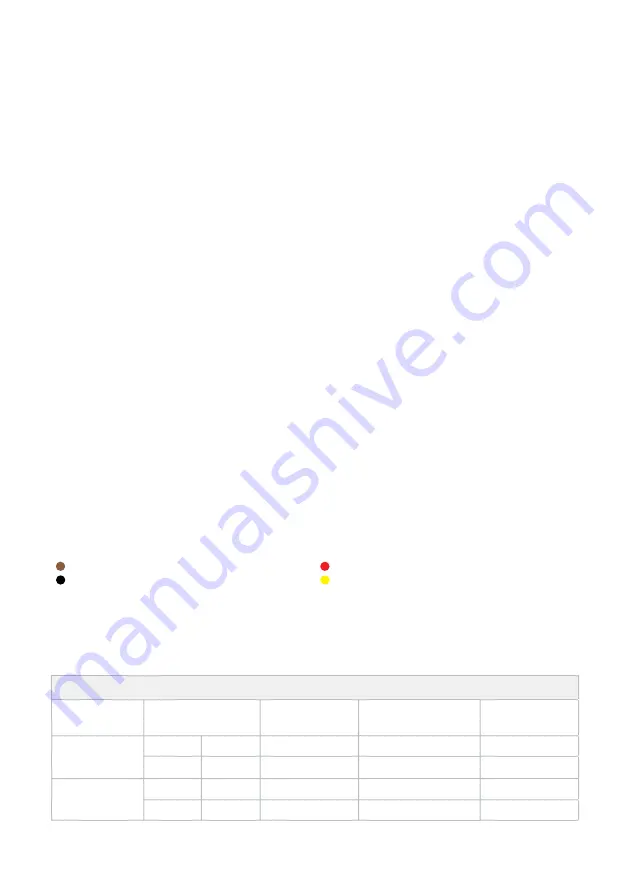

3.3 Cable sizing

The heavy gauge cables on BCDC Core 25 and Core 40 carry peak currents of up to 35 / 55 A

respectively. To carry this current effectively, the wire gauge required when extending this cables

depends on the length of cable run required.

"Table 3.3.1: Cable and Lug Sizing" (page 14)

for cable thickness requirements

for the following cables:

Brown*

Output Cable

Red

Vehicle Input Cable

Black

Ground Cable

Yellow

Solar Input Cable

*NOTE:

The Brown Output cable should be at maximum 1m in length.

Before making any connections run and layout the cables and wires required for your setup; trim

any excess if needed using side or cable cutters.

Table 3.3.1:

Cable and Lug Sizing

Part Number

Cable Install

Length

Cross

Sectional Area

Nearest Equivalent

B&S, BAE, AWG

Lug Cable

Size

BCDCN1225

1 – 5 m

3' – 16'

≥ 7.7 mm²

8

8 B&S / 10 mm²

5 – 9 m

16' – 30'

≥ 13.6 mm²

6

6 B&S / 16 mm²

BCDCN1240

1 – 5 m

3' – 16'

≥ 13.6 mm²

6

6 B&S / 16 mm²

5 – 9 m

16' – 30'

≥ 20.3 mm²

4

4 B&S / 25 mm²

Summary of Contents for BCDCN1225

Page 34: ...34 NOTES ...

Page 35: ...35 ...