16 | Installation

LUG CONNECTIONS

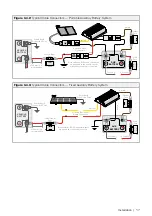

Cable lugs are commonly used when connecting cables

between components of the auxiliary battery system.

See

"Table 3.3.1: Cable and Lug Sizing" (page 14)

for

appropriate lug sizes in mm² to suit common B&S cable

gauges used in auxiliary battery installations.

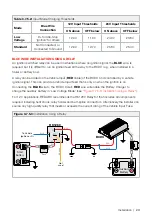

For a secure connection, strip back the cable roughly

12 mm—14 mm and fit the cable into the lug, then crimp

the lug down to secure the cable.

Do not use standard pre-insulated Red/Blue/Yellow crimp connectors for connection

of the BCDC Core’s 8 B&S cables as they are not rated to carry the required current.

REDARC fuse kits FK40 and FK60 include 4 × 10mm² (8 B&S) crimp lugs that allow

connection of the Vehicle Input and Output cables to the MIDI fuse holders in the kit.

For cables that require disconnection, such as when using a portable

battery box or portable solar panels, Anderson™ SB50 connectors

may be used. These connectors are commonly used where the

Battery Charger and auxiliary battery is mounted in a battery box or

in a trailer where it must be easily disconnected from the vehicle.

To ensure a secure connection into the Anderson plug contacts, cables smaller than 8 B&S

may need the exposed wire folded over on itself for a snug fit in the contact before crimping.

When crimping any of these connector types, REDARC recommends using a ratcheting or hydraulic

crimp tool as well as using heat shrink to prevent and shorting/contact with other components.

Summary of Contents for BCDCN1225

Page 34: ...34 NOTES ...

Page 35: ...35 ...