91

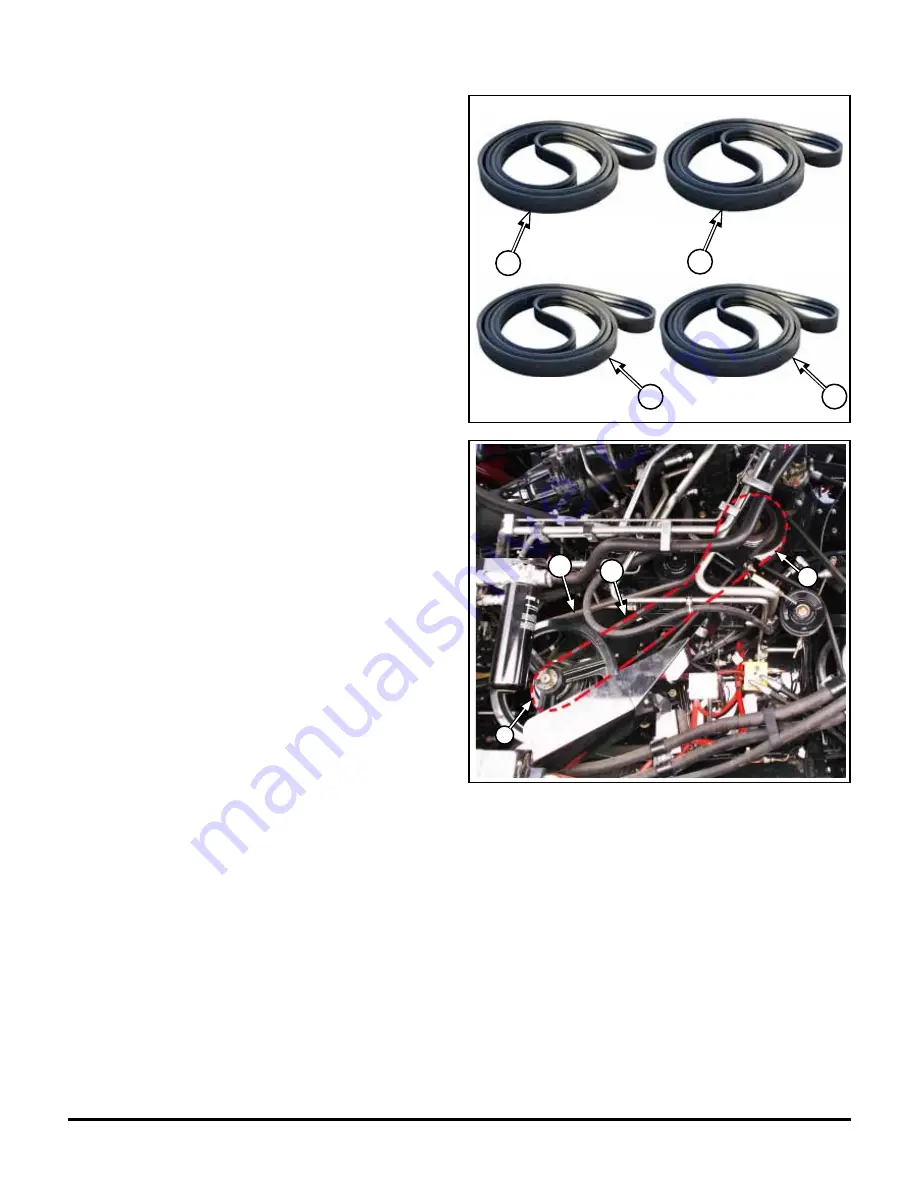

10.5 Re-install Drive Belts

Parts List:

Belts located in CS771BS Kit

BE2B117K VBelt 2B x 117L

(J)

Qty1

BE3B88K

VBelt 3B x 88L

(K)

Qty 1

BE3B135K

VBelt 3B x 135L

(L)

Qty 1

AFX 120 Series Only

Belt Located in CS961K Kit

86976208 VBelt 3B 2720mm

(M)

Qty 1

10.5.1

Install internal chopper high speed belt

(M)

- to

inside of factory sheave

(C)

and inside 3 grooves of

upper sheave

(J3)

- reuse belt that was removed

C

J3

J

L

M

J

K

M