REDEX-ANDANTEX DLO & DR SERIES

MOUNTING & MAINTENANCE INSTRUCTIONS

Product sheet

RX132/008

Version: 07/2006

English

1/3

This document must not be reproduced nor information therein disclosed without our authorization.

1. INTRODUCTION

REDEX-ANDANTEX phase shifters will give excellent service provided that the unit has been sized

properly and all the following conditions have been respected.

For selection/sizing, outline dimensions & mounting position see our catalogue or specific

application specifications.

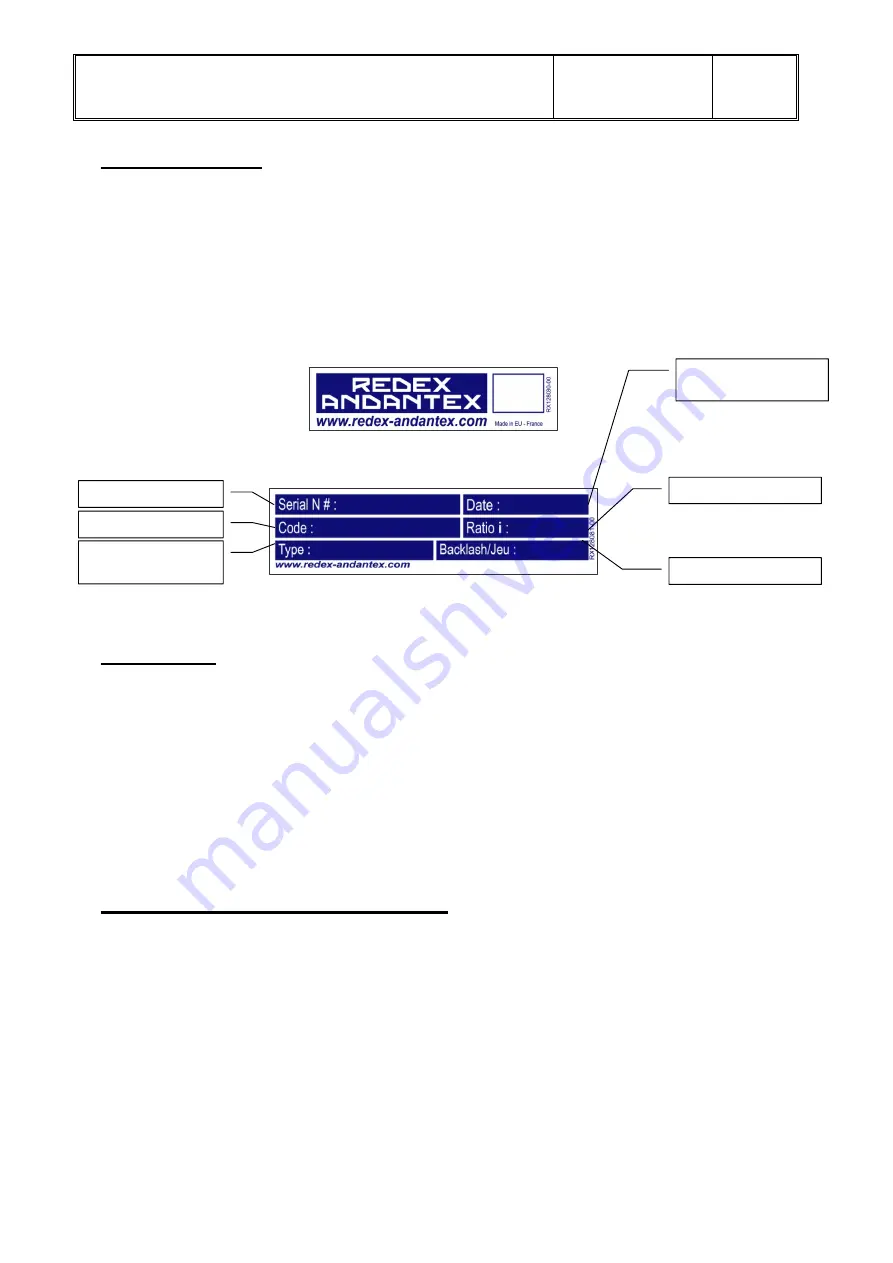

Each unit can be identified through its identification plate and the serial number indicated on it. The

serial number must be given for any correspondence on a particular unit.

OEM Plate

Gearhead Identification plate

869245

RX123350-00

DR5.123

25/10/05

2

First shipping date :

dd/mm/yy

Reduction ratio

Max. backlash (arcmin)

Serial number

Ordering code

Designation

(see our catalogue)

2. MOUNTING

Under no circumstances must the component be driven into place with a hammer.

The gearbox must be mounted on a rigid flat support, free from vibrations and able to withstand the

reaction torque. Ensure good alignment of the shafts.

Moreover, the mounting surface of the unit must be either the differential housing or the bevel box

housing but never both surfaces.

The keys delivered with the unit must be hand fitted to the keyway during the mounting process to

minimize backlash between the key and keyway.

3. MOUNTING OF ANCILLARY ITEMS

Remove grease from the shaft ends, before assembly, using a suitable solvent.

Important:

Ensure that the solvent does not come into contact with the oil seals and cannot seep

into the bearing housings.

The shaft ends are tapped for the mounting of ancillary components. Preheating the component to

be mounted will simplify the process. We recommend the use of an anti fretting-corrosion grease

type KLÜBER-PASTE-46-MR401

.

When using a coupling, we recommend a flexible coupling as opposed to a rigid coupling to

compensate for misalignment.