SRP - User manual

Ref.: RX182/006

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 15 / 28

6

MOUNTING OF THE SRP ON THE MACHINE FRAME

WARNING! HANDLING OPERATIONS.

The SRP unit can be handled by the main housing, the bevel box shafts, the fixing flange

holes or, with lifting rings by the output flange tapped holes.

First of all, clean the mounting surfaces to be fitted together: gearbox flange, pilot diameter, machine

surface, driven part on output.

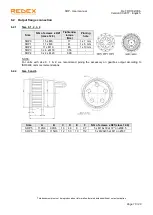

6.1 Gearbox fixing flange details

Size

n1 x D3c

Recommended

fixing screws

Tightening torque

(Nm)

SRP0

8 x 5,5

M5 class 12.9

10

SRP1

12 x 6,5

M6 class 12.9

17

SRP2

12 x 9

M8 class 12.9

41

SRP3

16 x 13,5

M12 class 12.9

145

SRP4

SRP5

12 x 17,5

M16 class 12.9

355

SRP6

12 x 22

M20 class 12.9

690

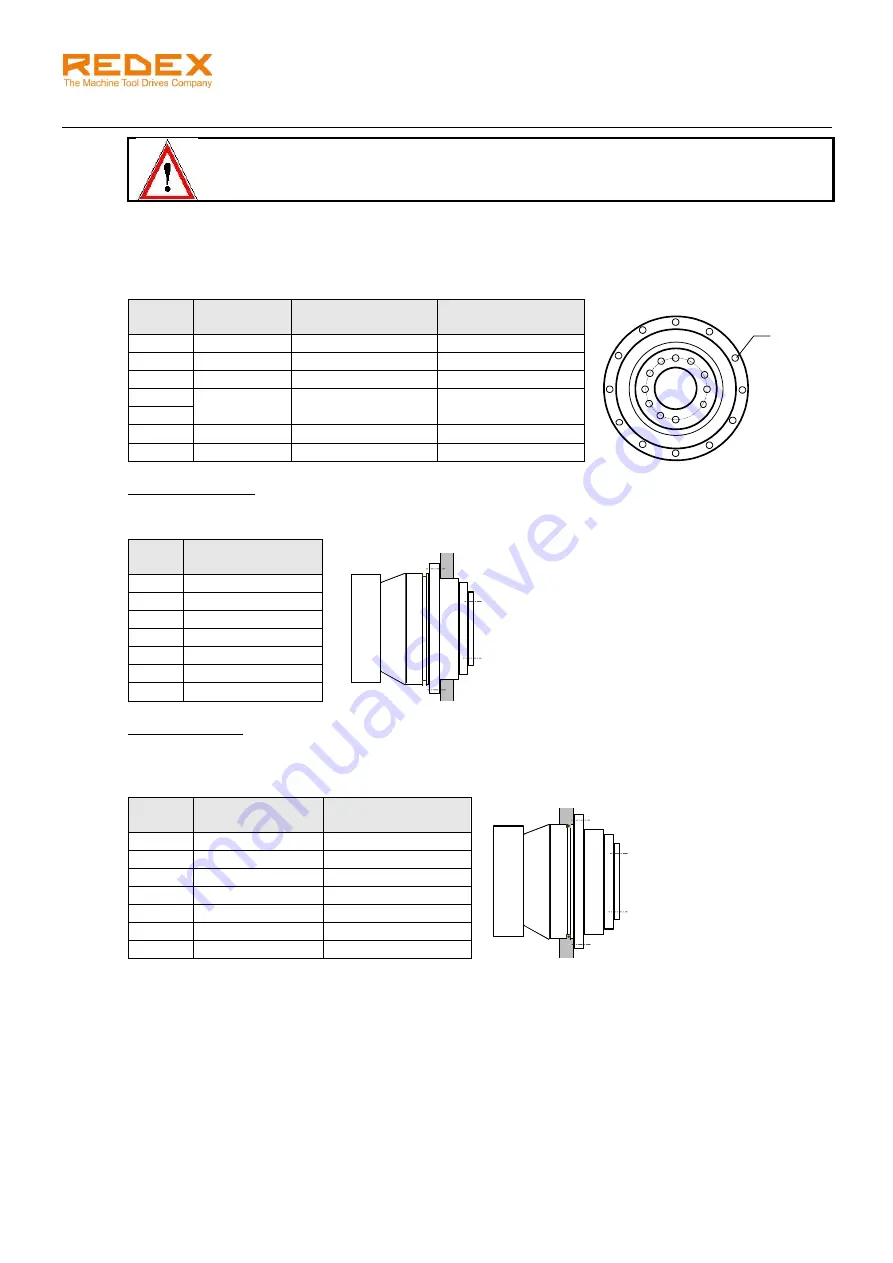

6.1.1

Output side fixing

The gearbox can be fixed from the output side using the pilot diameter D2d.

Size

Pilot diameter

D2d (mm)

SRP0

110h7

SRP1

140h7

SRP2

200h7

SRP3

255h7

SRP4

285h7

SRP5

355j6

SRP6

450j6

6.1.2

Input side fixing

The gearbox can be fixed from the input side using the pilot diameter D1c. This also allows sealing the

output side if needed.

Size

O-ring seal dim.

Pilot diameter D1c

(mm)

SRP0

108 to 113

120h7

SRP1

138 to 145

152h7

SRP2

192 to 200

212h7

SRP3

232 to 242

255h7

SRP4

259 to 270

285h7

SRP5

N/A

355j6

SRP6

N/A

450j6

n1 x D3c