SRP - User manual

Ref.: RX182/006

Version 01/2017 - English

This document must not be reproduced nor information therein disclosed without our authorization

Page 23 / 28

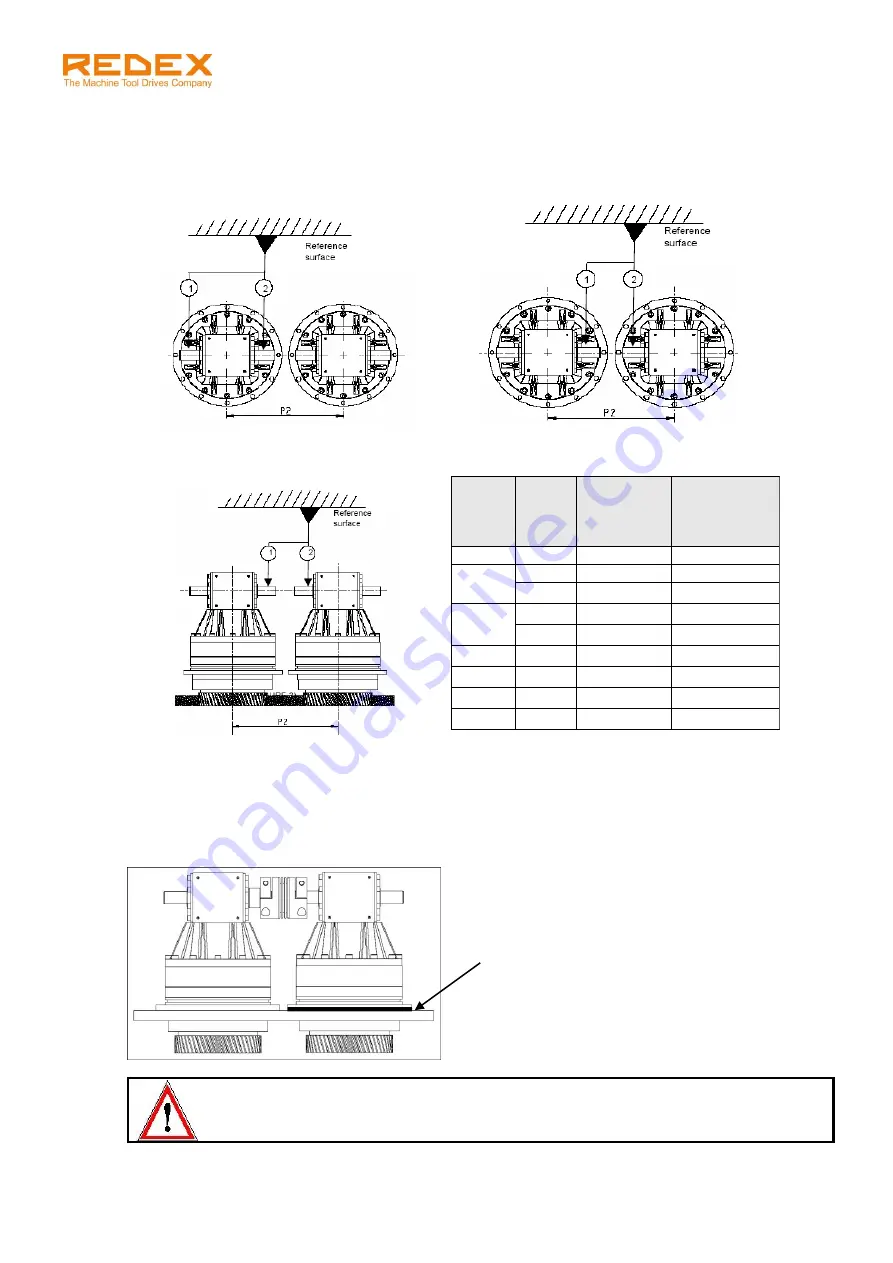

8.2 Shaft alignment

It is necessary to adjust the parallelism of the bevel box input shafts to insure proper coupling alignment.

Check the following parallelism from a reference surface related to the linear guide way. (Measures have

to be done at the middle of the shafts):

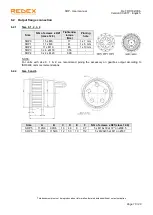

[FIGURE 1]

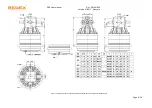

[FIGURE 2]

[FIGURE 3]

Size

Stage

Standard

axis dist.

P2

Max

parallelism

error

allowed

SRP0

1

263 mm

0,1 mm

SRP1

1

313 mm

0,1 mm

2

195 mm

0,1 mm

SRP2

1

344 mm

0,1 mm

2

263 mm

0,1 mm

SRP3

2

313 mm

0,1 mm

SRP4

2

344 mm

0,1 mm

SRP5

2

425 mm

0,1 mm

SRP6

2

540 mm

0,1 mm

To adjust the parallelism represented in [Figure 1] & [Figure 2], turn the SRP around the output pinion

axis.

To adjust the parallelism represented in [Figure 3], it is necessary to insert shims between the machine

frame and the fixing flange of the SRP.

WARNING!

Before mounting the SRP on the machine, check the relative rotation of input shaft and

output pinion. Both SRP units must be installed with the same direction of rotation.

Shims