16

11.0 TROUBLE SHOOTING (PROBLEM ANALYSIS)

Problem

Possible cause

Solution

Too little decompaction

-

Working depth is

adjusted too shallow

-

Subsoil is too hard

-

Adjust the machine to

more depth

-

Drive

slower

-

Adjust the working depth

to less depth and continue

to work again.

Brushes not turning more

-

Drive is faulty

-

Check the driveline

Creaking noises while in

operation of the machine.

-

Bearings need lubrication

/are worn out.

-

Lubricate the bearings with

EP2 grease/replace the

bearings.

Chains shooting over the

sprockets.

The chains tension is not

correct.

-

Chains/sprockets

are

worn out.

-

Adjust the chain tension

-

Replace the chains/sprockets.

12.0 MAINTENANCE

Time schedule

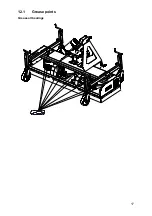

Check/Grease point

Method

Before

every

use

Check for loose bolts/nuts

Presence and readability of the

safety stickers

(Please refer to Figure

5)

Tighten loose bolts/nuts with

the correct tightening moment

Replace these if not present or

damaged

After

every

20 working hours

Chain tension

Adjust tension if needed

After

every

50 working hours

or annually

Grease the bearings

Grease the chain

Use EP2 grease

Silicone spray

After

every

500 working

hours

Change the oil of the gearbox

Check Gearbox

0.5L (0.13 Gallon) 80W-90

Inspect all parts and replace or

rear parts if needed.