20

hole at support AD. When the shaft is in place mount bolt S with washer R. Do not tighten the

bolt.

6.

Continue to do exactly the same at the other side of the machine. Since the wheel kit is

symmetric, all parts are the same.

7.

When all parts are in place, tighten all bolts and nuts. Check whether the alignment of the wheel

is okay, which can be adjusted, since the bolts do have some play in the holes. Be sure all bolts

are tight, which needs to be checked regularly.

8.

The (top) draw bar AN can be fitted to the standard toplink pin of the machine. Next connect the

other toplink AK end with bolt AO to the drawbar AN and tighten it with nut AM.

9.

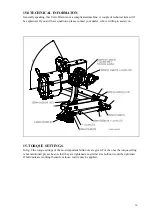

The last step is preparing the hydraulic circuit. Similar components are identical. Connect tubes F

to the T connector C, assemble the fitting blocks E with bolt/ nut/ washer D to a slot in the front

cover of the machine. Do not tighten a thing. Slide the angle connectors AE on the tubes. Note

one faces down, the other about 45 degrees to the rear, see the figure. Fit the nipples X to the

hydraulic cylinder ( Use cupper washers, not drawn, if necessary ). Next connect the hoses AB

(all are identical) to the hydraulic cylinder and connect them with AE. Look at the drawing for

the position of the hoses. When everything is in line and both sides are prepared as described

above, everything can be tightened. BE SURE that all tubes and hoses are fully inserted into the

connectors, before tightening them.

10.

Assemble both supply hoses B to the machine and the quick connectors A. If the quick connector

does not fit the tractor, source them locally.

16.0.2 SOME GUIDELINES FOR WHEEL KIT USE.

When the machine is used with an hydraulic wheel kit, be aware of the following:

-

The unit has no brakes. Highway use is limited to 25 km/h (15 mph)

-

Check the national legislation for highway use.

-

When the machine is in use, leave the wheels on the ground. A free floating hydraulic valve at

the tractor is necessary.

-

Tyre pressure should range from 1.0 – 2.0 bar (14-28 PSI). Note when used at 1.0 bar the

maximum transport speed is 16 km/h (10 mph).

-

The maximum hydraulic system pressure is 175 bar (2400 PSI).

-

Never disconnect the hoses from tractor when machine is raised from the ground. Always ensure

that machine is tight on the ground with locked rear roller supports and relieved oil pressure,

before disconnecting the hoses. (see also par.11.0)

-

When the working depth is adjusted, always reset the machine at 90 degrees with toplinks.

-

Check bolts/nuts regularly.

-

Watch your turns when machine is raised. Damage to the PTO may occur

-

Do make straight passes during work, no turns allowed.

When at any moment some body should be close to the machine for repair, maintenance,

adjustment etc with the machine in the raised position, ALWAYS secure the machine by

locking the rear roller at the lowest position with pin 10 ( fig.2.).