12

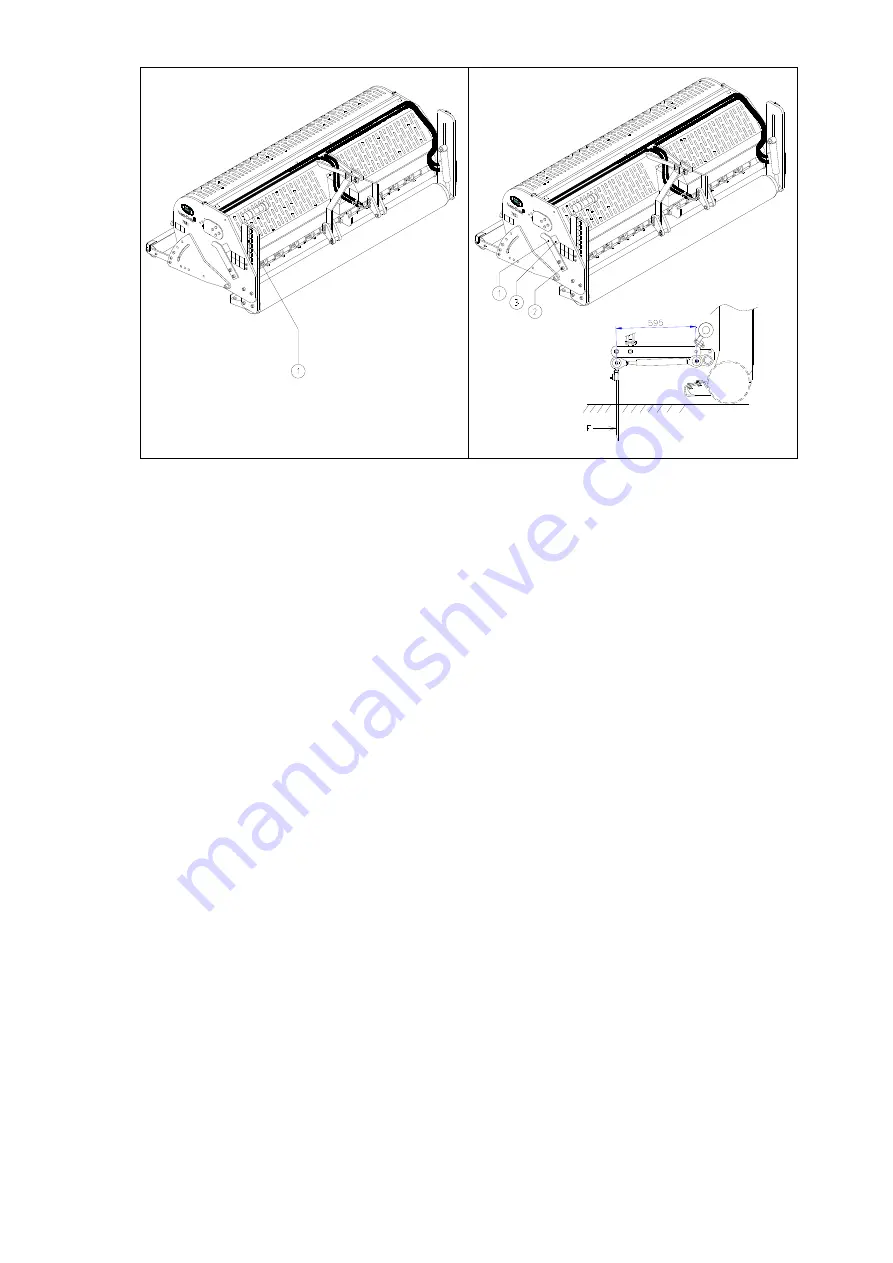

Fig. 11

Fig. 12

4.0 OPERATING-DEPTH ADJUSTMENT

The operating depth can be adjusted when the machine is raised (before start of use)

or during operation in the ground when the machine is in use, see fig. 11.

The machine is equipped with a hydraulic operating-depth adjustment that can be

operated from the tractor by activating the hydraulic output of the tractor.

The label (1) on the side of the machine indicates the depth setting.

@

Make sure that both sides of the machine raise or lower evenly.

If not, stop the movement immediately to prevent damage to the machine.

To remove trapped air from the hydraulic operating-depth adjustment, see chapter 2.0

points 12 through 14.

@

The depth-adjustment on the decals only applies when 400 mm (16”) long pins are used.

When shorter pins are used, subtract the difference in length, compared to 400 mm (16”),

from the value shown on the decals.

5.0 PIN ANGLE ADJUSTMENT

All pins can simultaneously be adjusted with one handle (1), which is located on the side of

the machine; see fig. 12. Lift the machine above the ground and loosen counter nuts (2) on

both sides of the machine. Adjust the angle by turning the handle (1). The angle can be read

on indicator (3). Then retighten counter nuts (2).

@

An angle of 90 degrees means almost no draught. This is required for hollow pins and is

advised for the 8 mm (5/16”) pins.

@

From 90 to 75 degrees means more draught. This is advised for solid pins and is

dependent of the ground conditions, the pin size and the client’s preference.

@

At 90 degrees, the pins only go straight into the ground if the machine is correctly

installed, see fig. 8. If this is not correct, force F can be produced, see fig. 12, which will

damage the machine.

@

The length of the assembled drawbar must be 595 mm (23.4”), which can be

calibrated using shims. (see parts page)