Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or in an elevated position that could allow the unit to fall or be tipped

over.

Always replace a damaged gauge before operating the unit again.

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

Always ensure that the tool has stopped before connecting to the air supply.

Do not wear watches, rings, bracelets, or loose clothing when using any air tool.

Do not overload the tool. Allow the tool to operate at its optimum speed for maximum efficiency.

Do not use a tool that is leaking air, with missing or damaged parts, or that requires repairs.Verify that all screws are

securely tightened.

For optimal safety and tool performance, inspect the tool daily in order to ensure free movement of the trigger, safety

mechanisms, and springs.

Always keep your air tools clean and lubricated. Daily lubrication is essential to avoid internal corrosion and possible

failures.

Ensure the floor is not slippery and wear non-slip shoes. Floors should be kept clean can clear.

Always follow all workshop safety rules, regulations, and conditions when using the tools.

Carry the tool by the handle only. Do not carry the tools with a finger on the trigger. Do not carry the tool by the hose,

magazine or any other parts.

Do not use the tool near or below freezing temperatures, as doing so may cause tool failure.

Do not store the tool in a freezing environment to prevent ice formation on the operating valves of the tool, as doing

so may cause tool failure.

Handling and storage of oil: Use with adequate ventilation. Avoid contact of oil with eyes, skin, and clothing. Avoid

breathing spray or mist. Store in a tightly closed container in a cool, dry, well-ventilated area free from incompatible

substances.

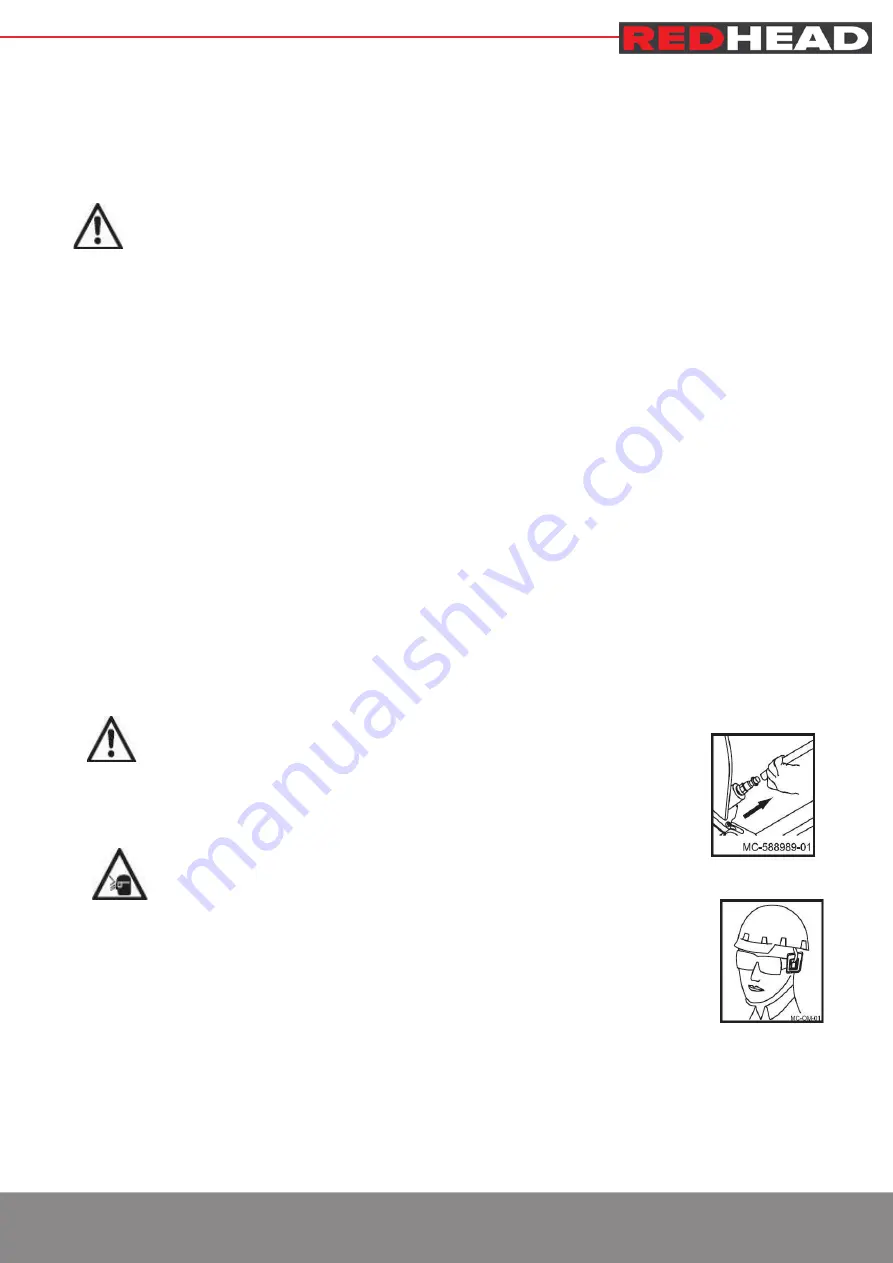

CAUTION!

Potential hazard that may result in moderate injury or damage to equipment.

Disconnect tool from the air supply and turn off the compressor before performing any

maintenance, or changing accessories, when the tool is not in use, when it is being handed to

another person, and when it is left unattended. Failure to comply may result in moderate injury or

damage to equipment.

Use safety goggles and ear protection:

Wear safety glasses with side shields when operating the tool/compressor and verify that others in

the work area are also wearing safety glasses. Safety glasses must conform to

American

national standards institute (ANSIZ87.1)

Requirements and must provide protection from flying particles from the front and the sides.

Air powered tools are loud and the sound can cause hearing damage. Always wear ear protection

to prevent hearing damage and loss. Failure to comply may result in moderate injury.

NOTE: Recycle unwanted materials father than disposing of them as waste. Sort the tools, hoses, and package into

specific categories and take to the local recycling centre or dispose of them in an environmentally safe way.