US-15

BCZ3050S/T/SW

U

S

9. Maintenance

.038 in

1.00mm

MA4

(1)

MA2

MA1-d

(1)

MA3

• Make sure that the engine has

stopped and is cool before

performing any service to the

machine. Contact with moving

cutting head or hot muffler may

result in a personal injury.

■

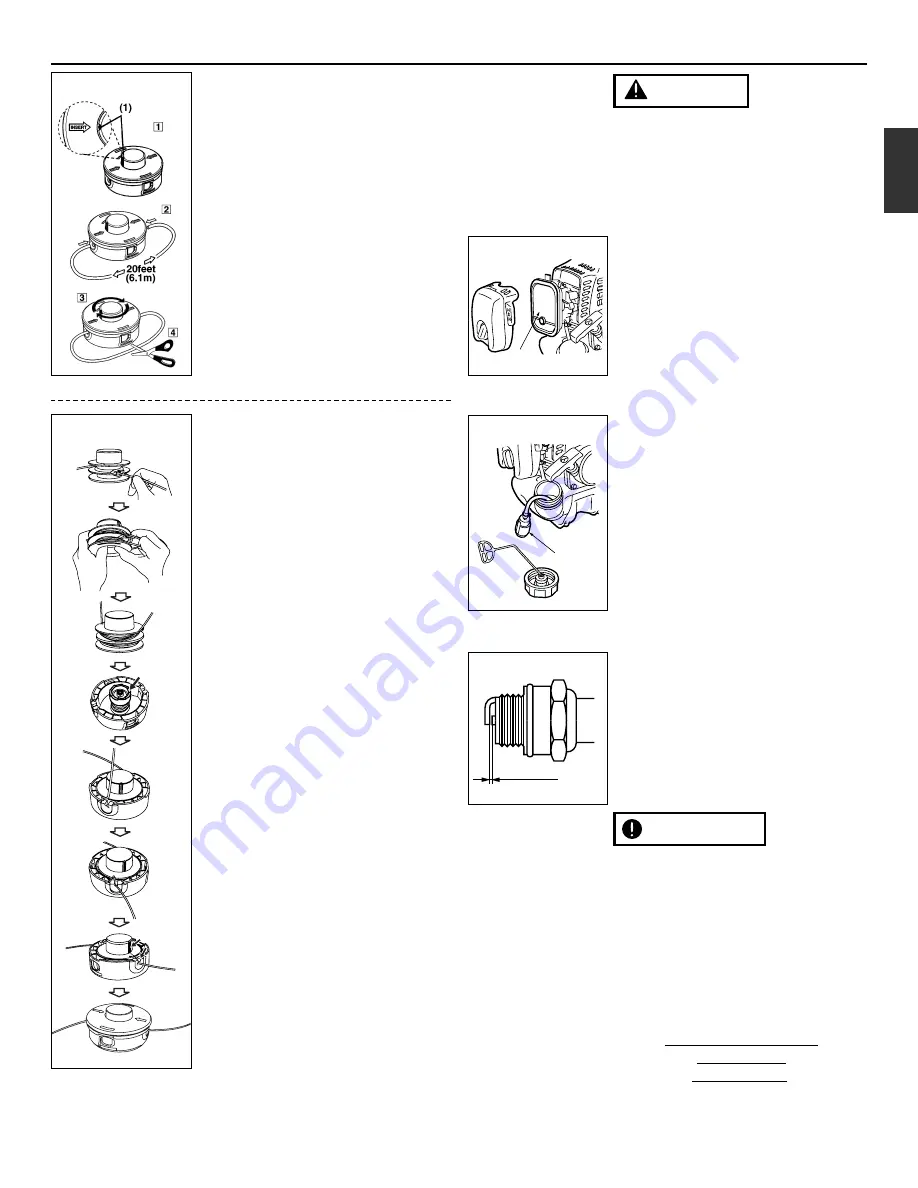

AIR FILTER

• The air filter, if clogged, will reduce the

engine performance. Check and clean

the filter element. If the element is

broken or clogged, replace with a new

one. (MA2)

(1) air filter

■

FUEL FILTER

• When the engine runs short of fuel

supply, check the fuel cap and the fuel

filter for blockage. (MA3)

(1) fuel filter

■

SPARK PLUG

• Starting failure and mis-firing are often

caused by a fouled spark plug. Clean

the spark plug and check that the plug

gap is in the correct range. For a

replacement plug, use the correct type

specified by RedMax. (MA4)

• REPLACEMENT PLUG IS A NGK

CMR7H-10.

• Note that using any spark plug other

than those designated may result in the

engine failing to operate properly or in

the engine becoming overheated and

damaged.

• To install the spark plug, first turn the

plug until it is finger tight, then tighten it

a quarter turn more with a socket

wrench.

TIGHTENING TORQUE:

87~104 in-lbs

(9.8~11.8 N.m.)

IMPORTANT

WARNING

MA1-c

Twist and load installation (MA1-c)

1. Align notch on bump knob with either

insert arrow.

2. Insert the two ends of a 20 feet piece of

trimmer line into each eyelet. Pushing

line into the channel of the spool

approximately 2 inches.

3. Hold housing of trimmer head and turn

bump knob clockwise.

4. Cut remaining trimmer line to separate

into two pieces.

(1) Notch

Manual installation (MA1-d)

1. Take a 20 foot length of .095 Cable

Twist line and cut in half and insert

each end of the line into both line

holding holes located in the center

separation rib. (Note: the line needs to

be pushed into each hole 2.5 inches or

55mm until it stops.)

2. Hold the spool opening toward you and

bump button away from you. Wind the

line in the direction or arrow on the

spool body, by placing your index finger

between the two strands and wind line

tightly and evenly in the clockwise

direction.

3. Stop when approximately 15-20cm (6-8

inches) of line remains and place the

ends of the line firmly in the notches in

the top ring of the spool.

4. Insert the spool over the drive cam

(white) with notches lining up with

aluminum line guide eyelets.

5. Pull each end of the line from the

holding notches and place the line

inside of the aluminum line guide

eyelets.

6. Align the locking tabs of the cover with

the locking holes in the head.

7. Push the cover down and make sure

the cover tabs snap into the locking

slots securely.