US-18

BCZ3050S/T/SW

12. Optional blade usage (for BCZ3050S/SW only)

■

STARTING THE ENGINE

Please refer 5.For safe operation (P.6),

8.Operation (P.12).

• The product is equipped with a

centrifugal clutch mechanism, so

the cutting attachment could rotate

as soon as the engine is started.

When starting the engine, place the

product onto the ground in a flat

clear area and hold it firmly in place

so as to ensure that neither the

cutting part nor the throttle come

into contact with any obstacle when

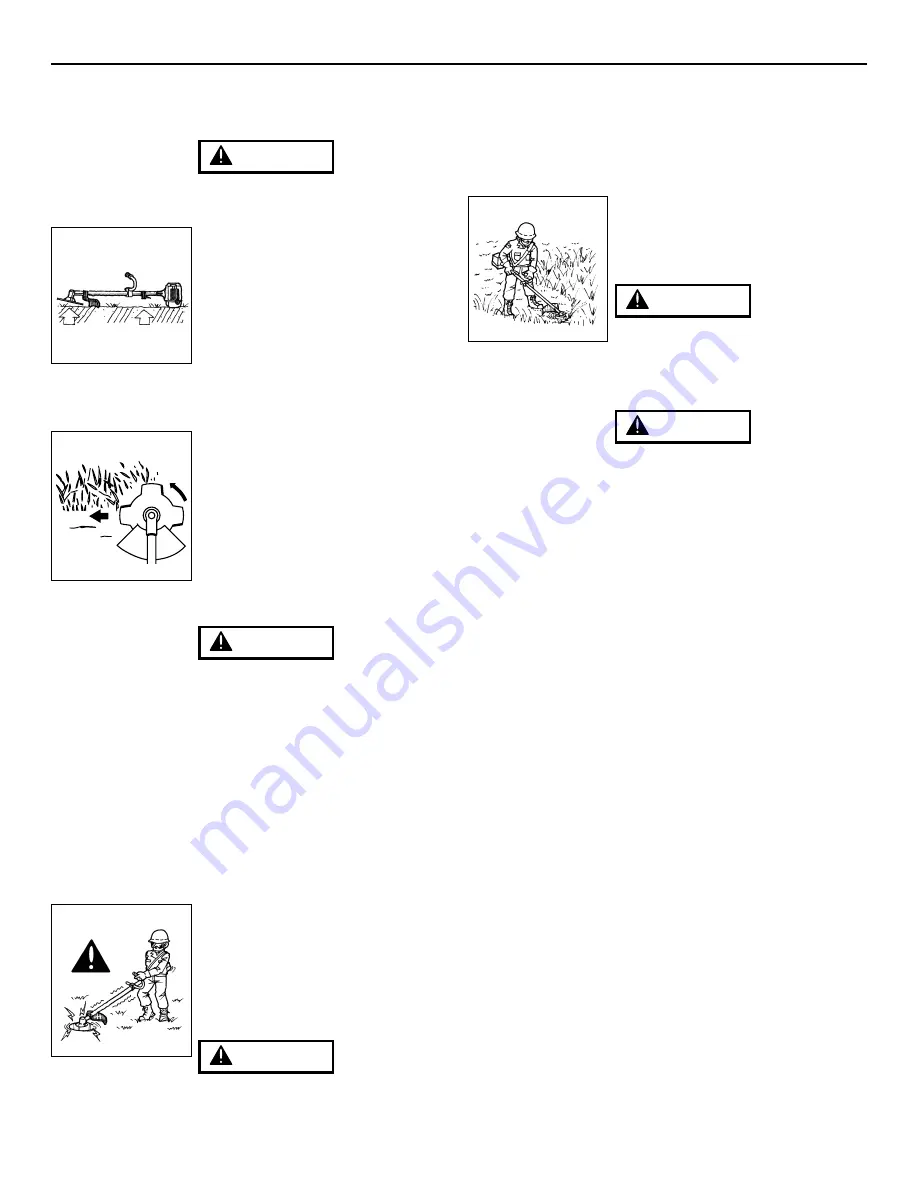

the engine starts. (OPT6)

■

CUTTING METHOD

a) Use the front left side cutting.

b) Guide the blade from your right to left

with it tilted slightly to your left. (OPT7)

c) When mowing a wide area, start

working from your left end to avoid

interference of cut grass.

d) The blade may be seized by weeds if

the engine speed is too low, or the

blade cuts too deep into weeds. Adjust

the engine speed and cutting depth

according to the condition of object.

• If the grass or other object gets

caught in the blade, or if the unit

starts to shake or vibrate, turn off

the engine and check the whole unit.

Change the blade if it has been

damaged.

• Turn off the engine and make sure

the blade has completely stop

before checking the blade, and

removing any object got caught in.

■

OPERATION

1. Check the bolt to fasten the blade and

be sure the bolt has no fault, and no

abrasion.

2. Be sure that the blade and the holder

have been fastened according to

instruction and the blade turns

smoothly without abnormal noise.

(OPT8)

• The rotating parts fastened

incorrectly may cause serious

accident to the operator.

WARNING

WARNING

WARNING

OPT7

OPT6

OPT8

OPT9

• Make sure that the blade is not bent,

warped, cracked, broken or

damaged.

• If you find any error to the blade,

discard it and change new one

which is certified by RedMax.

■

By using the shoulder strap, hang the

unit on your right side. Adjust the strap

length so that the cutting head may

become parallel to the ground. (OPT9)

Make sure to use shoulder strap and

cutting attachment guard. If not, it is

very dangerous when you slip or lose

your balance.

■

CONTROLLING BLADE THRUST

• Blade thrust can cause serious

personal injury.

Carefully study this

section.

It is important that you

understand what causes blade thrust,

how you can reduce the chance of

blade thrust and how you can remain in

control of the unit if blade thrust does

occur.

1. What causes blade thrust:

• Blade thrust can occur when the

moving blade contacts an object that it

cannot cut. This contact causes the

blade to stop for an instant and then

suddenly move or ”bounce” away from

the object that was hit. The operator

can lose control of the unit and the

blade can cause serious personal injury

to the operator or any person nearby if

the blade contacts any part of the body.

2. How you can reduce the chance of blade

thrust:

a. Recognize that blade thrust can

happen. By understanding and

knowing about bounce, you can

help eliminate the element of

surprise.

b.

Cut fibrous weeds and grass

only.

Do not let the blade contact

materials it cannot cut such as hard,

woody vines and brush or rocks,

fences, metal, etc

c. Be extra prepared for blade thrust if

you must cut where you cannot see

the blade making contact such as in

areas of dense growth.

WARNING

WARNING