US-6

BCZ3050S/T/SW

contain dangerous carbon monoxide.

10. Never to touch the spark plug or plug cord

while the engine is in operation Doing so

may result in being subjected to an

electrical shock.

11.Never to touch the muffler, spark plug,

other metallic parts of the engine or

engine cover while the engine is in

operation or immediately after shutting

down the engine. These metallic parts

and engine cover reach high

temperatures during operation and doing

so could result in serious burns.

12.To reduce the risk of injury associated

with contacting rotating parts, stop the

engine before installing or removing

attachments. Always disconnect the spark

plug before performing maintenance or

accessing movable parts.

■

Before use

1. Each time before starting the engine,

inspect the entire unit to see if every part

is in good order and is securely tightened

in place. If any damage is found in the fuel

line, the exhaust line, or the ignition wiring,

do not use the product until it has been

repaired.

2. Before starting operation, always make

sure that the cutting attachment and the

debris guard are properly installed and

securely fastened.

3. If the cutting head is the metal blade,

change the guard and handle as shown in

the Owner's manual (see P17).

4. Check the condition of working area to

avoid any accident by hitting hidden

obstacles such as stumps, stones, cans, or

broken grass.

Remove any obstacle before beginning work.

■

Starting the engine

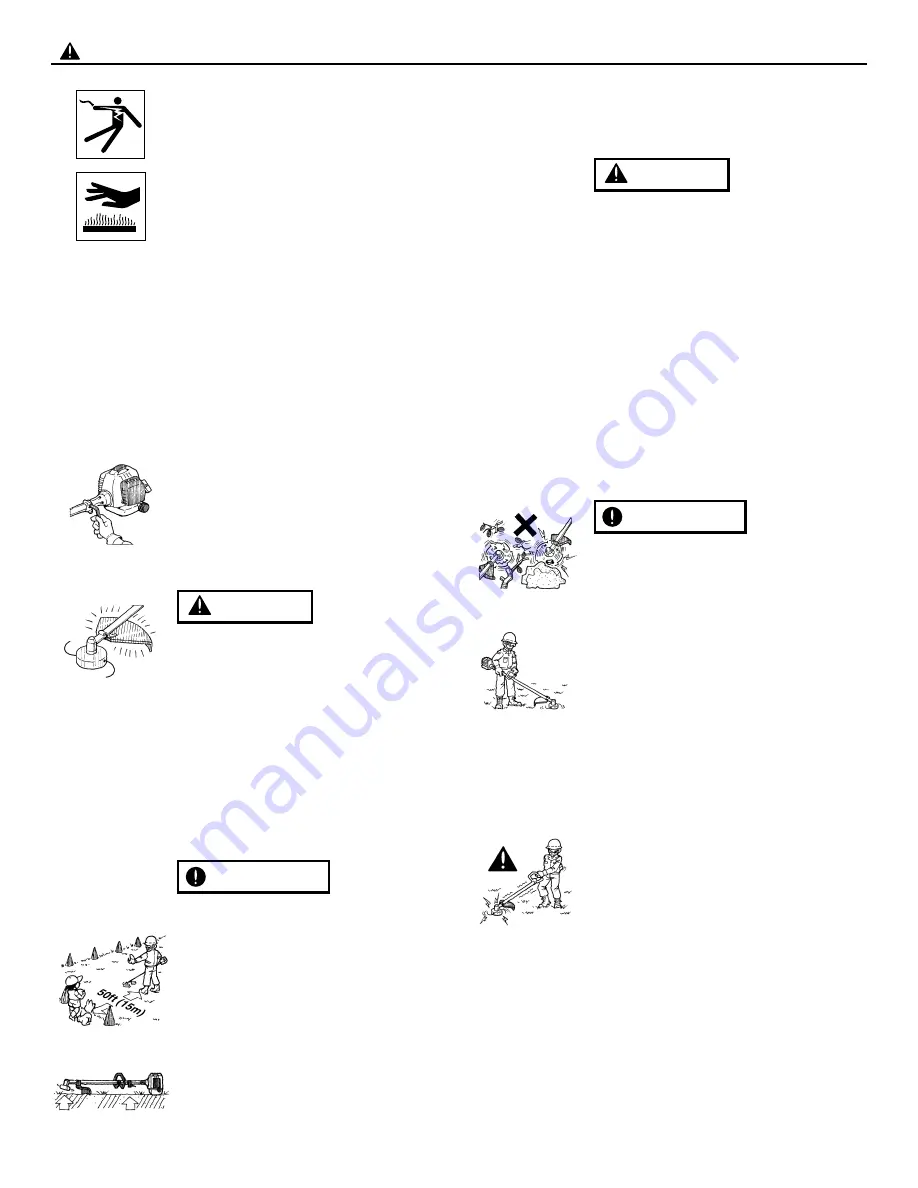

1. Keep bystanders and animals at least 50

feet (15 meters) away from the operating

point. If you are approached, immediately

stop the engine.

2. The product is equipped with centrifugal

clutch mechanism, so the cutting

attachment could rotate as soon as the

engine is started. When starting the

engine, place the product onto the ground

in a flat clear area and hold it firmly in

IMPORTANT

WARNING

5. For safe operation

place so as to ensure that neither the

cutting part nor the throttle come into

contact with any obstacle when the engine

starts.

Make sure the throttle is at idle position.

Never place the throttle into the high

speed position or half throttle position

(throttle lock position) when starting the

engine.

3. After starting the engine, check to make

sure that the cutting attachment stops

rotating when the throttle is moved fully

back to its original position (idle position). If

it continues to rotate even after the throttle

has been moved fully back, turn off the

engine and take the unit to your authorized

RedMax servicing dealer for repair.

■

Using the product

Cut only materials recommended by the

manufacturer. And use only for tasks

explained in the manual.

1. Grip the handles firmly with both hands

using your whole hand. Place your feet

slightly apart (slightly further apart than the

width of your shoulders) so that your

weight is distributed evenly across both

legs, and always be sure to maintain a

steady , even posture while working.

2. Keep cutting attachment below waist level.

3. Maintain the speed of the engine at the

level required to perform cutting work, and

never raise the speed of the engine above

the level necessary.

4. If you detect abnormal vibration or noise

during operation, promptly stop the product

and check whether something has broken.

If a breakedown has occurred, do not

operate the product until the problem is

fixed.

5. Keep all parts of your body away from

rotating cutting attachment.

6. Guard against hazardous situations at all

times. Warn adults to keep pets and

children away from the area. Be careful if

you are approached. Injury may result from

flying debris.

7. If someone calls out or otherwise interrupts

you while working, always be sure to turn

off the engine before turning around.

8. After using the product and other

IMPORTANT

WARNING