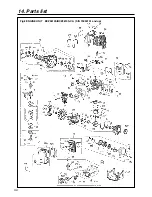

Fig.2 ENGINE UNIT

BCZ2610S/BCZ2610S-CA (S/N 70050101 and up)

57

Key#

Description

Part Number

Q'ty

1

CYLINDER

848-F3R-12A2

1

2

GASKET, base

848-F3R-12B0

1

3

BOLT, M5x22

4820-12130

2

4

INSULATOR

848-F40-14A0

1

5

GASKET, insulator

848-F40-14B0

1

6

GASKET, carburetor

T1590-13130

1

7

7, SCREW,M3x6

848-853-0600

2

8

REEDVALVE (S) ASSY

848-F3R-1601

1

9

• TUBE

848-8F4-0550

1

10

• PUMP ASSY

848-F40-8800

1

11

• REEDVALVE

848-F3R-16C0

1

12

• STOPPER

4810-16130

1

13

• SCREW, M3x8

4810-16170

1

14

PIRE AIR (S)

848-F3R-16E0

1

15

REEDVALVE (F) ASSY

848-F3R-1611

1

16

• REEDVALVE

848-F3R-16C0

1

17

• STOPPER

4810-16130

1

18

• SCREW, M3x8

4810-16170

1

19

PIPE AIR (F)

848-F3R-16F0

1

20

GASKET, valve

848-F3R-16H0

2

21

SCREW

4810-16180

6

22

CRANKCASE COMP.

4810-21101

1

23

• PIN

2629-21130

3

24

GASKET

4810-21140

1

25

BEARING

06030-06001

2

26

SEAL

4810-21210

1

27

SEAL

1850-21220

1

28

SNAP RING

04065-02812

1

29

BOLT, M5x30

4820-21310

3

32

PISTON

848-F40-41A0

1

33

RING

848-8C3-4101

2

34

PIN

848-8B8-2800

1

35

RING

1260-41320

2

36

BEARING

T1551-41410

1

37

WASHER

848-873-8002

2

38

CRANKSHAFT COMP.

848-F3R-4200

1

39

NUT

1650-43230

1

40

KEY

1000-43240

1

41

ROTOR

4810-71110

1

42

COIL ASSY

T1512-71200

1

43

• CORD

T1512-71220

1

44

• CAP

2616-71320

1

45

SPACER

1260-71261

2

46

BOLT, M4x22

4820-72150

2

47

CARBURETOR ASSY

848-F40-8100

1

48

• REBUILD KIT

848-F60-0630

1

49

• • BODY ASSY

1850-81450

1

50

• • GASKET KIT

4810-06021

1

51

• BODY

848-F40-81G0

1

52

• COVER

1850-81520

1

53

• PUMP

1751-81510

1

54

• RING

1751-81130

1

55

• SWIVEL

1881-81140

1

56

• SCREW

1752-81110

2

57

• BRACKET

5500-81120

1

58

• NUT

1751-81180

1

59

• SCREW

1918-81170

1

60

• SCREW

1850-81530

4

61

• WASHER

5500-81160

1

76

SCREW, M5x60

4820-82310

2

77

MUFFLER ASSY

848-F40-1510

1

79

• ARRESTER

4810-15140

1

Key#

Description

Part Number

Q'ty

80

BOLT, M5x50

4820-15310

2

81

GASKET

848-F3R-15C0

1

82

PLATE, muffler

848-F3R-15D0

1

83

COVER ASSY

848-F30-5303

1

84

• COVER COMP.

4810-31102

1

85

• • COVER, fan

4810-31111

1

86

• • DRUM

848-F30-51A1

1

87

• • SNAPRING

04065-02812

1

88

• • BEARING

T1701-31150

1

89

• • SNAP RING

04064-01210

1

90

• BRACKET (A)

6470-31211

1

91

• BRACKET (B)

6470-31221

1

92

• CUSHION

6470-31230

1

93

• BOLT, M5x30

4820-21310

2

94

• BOLT, M5x14

T1501-32120

1

95

SCREW, M5x16

4820-32120

5

96

COVER, engine

848-F3R-31A0

1

97

PLATE

848-F3R-12G0

1

98

SCREW, M5x10

4820-12350

2

99

SHOE

4820-51110

2

100

SPRING

4820-51220

1

101

SCREW

1140-51250

2

102

WASHER

1140-51230

2

103

WASHER

1140-51242

2

104

CAP

848-F30-71C2

1

105

SPRING

1900-72120

1

106

CORD

4810-71240

1

107

CORD, earth

4810-71250

1

108

TUBE

T1512-71320

1

109

PLUG, NGK CMR7H

3699-91867

1

110

GROMMET

4810-72120

1

111

RECOIL ASSY

4810-75100

1

112

• REEL

4500-75120

1

113

• SCREW

4500-75150

1

114

• SPRING, spiral

1850-75130

1

115

• COLLAR

4500-75180

1

116

• ARM

4500-75190

1

117

• ROPE

4810-75160

1

118

• KNOB

3330-75421

1

119

• PLATE, stopper

4810-75170

1

120

PULLEY

4500-75210

1

121

SCREW, M5x16

T1501-32120

2

122

BODY ASSY

4810-82100

1

123

• PLATE, choke

4810-82130

1

124

• LEVER, choke

5500-82140

1

125

• SCREW

2630-33610

1

126

ELEMENT

4810-82170

1

128

COVER ASSY

848-F40-832

1

129

• KNOB

5500-82221

1

130a TANK ASSY

848-F34-8501

1

130b TANK ASSY (CA Only)

848-F43-8501

1

131

• CAP ASSY

T1015-85202

1

132

• • HOLDER ASSY

4500-85300

1

133

• • PACKING

4500-85220

1

134

• • FILTER

5601-85260

1

135

• • STOPPER

4820-85260

1

136

• PIPE COMP.

4810-85300

1

137

• FLTER ASSY

3302-85400

1

138

• CLIP

1260-85460

1

139

SCREW, M5x16

4820-85510

3

140

LABEL, recoil

848-F40-90D0

1

141

LABEL, cover

848-F60-90B0

1

142

GUARD

T1506-31910

1

143

BOLT, N5x22

4820-12130

2

144

CLIP

1950-86120

1

145

LABEL

4810-82230

1