38

9. Maintenance

(EX2-BC only)

EX2-BC

MA1

■

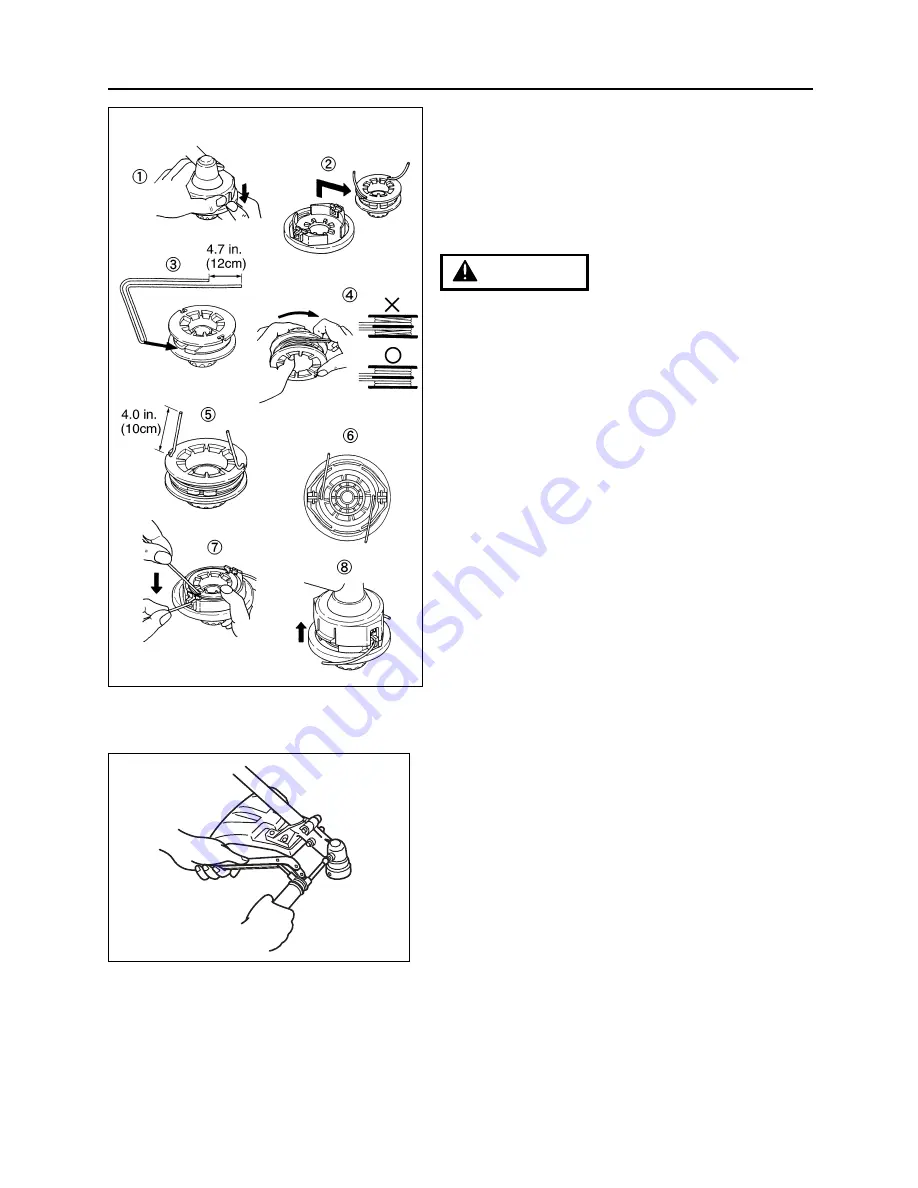

REFILLING TRIMMING LINE (MA1)

1. For replacement line, use a diameter of .095in

(2.4mm). The spool is capable for a line upto

20ft (6m) on the 4” head. Avoid using a larger

line as it may cut down the trimming

performance.

For safety reasons, do not use

metalreinforced line.

2. Pinch the slotted area on the both sides of the

spool housing to unhook the bottom cap.

3. Take out the spool and pull off the old line. Fold

new line so that one half line is 4.7in.(12cm)

shorter than another half.

4. Wind up the line in the correct direction as

indicated on the spool.

5. Hook each end of the line in the slot on the edge

of the spool, and then put the ends through the

eyelets on the housing. Make sure that the

spring and the washers are in place.

6. While holding the spool against the housing, pull

the line ends to release them from the slot.

7. Line up the slot on the bottom cap with the hook

on the housing, press the cap against the

housing until it clicks.

■

GEAR CASE (MA2)

• The reduction gears are lubricated by

multipurpose, lithium-based grease in the gear

case. Supply new grease every 25 hours of use

or more often depending on the job condition.

• Remove the cutter holders before installing new

grease to arrange for old grease to exit.

WARNING

EX2-BC

MA2

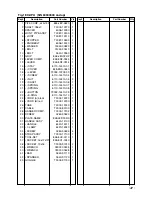

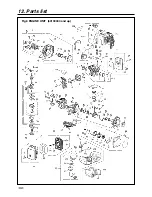

Summary of Contents for EXtreme EX-HE

Page 46: ...12 Parts list 46 Fig 1 EXZ PU S N 60300000 and up...

Page 48: ...12 Parts list 48 Fig 2 EX2 BC S N 50200000 and up...

Page 50: ...Fig 3 ENGINE UNIT 60100000 and up 50 12 Parts list...

Page 52: ...12 Parts list 52 Fig 4 EX LRT S N 000531 and up...

Page 54: ...12 Parts list 54 Fig 5 EX PS S N 000000 and up...

Page 56: ...12 Parts list 56 Fig 6 EX HE S N 000101 and up...