3/4 Page

EMISSIONS SERVICE BULLETIN

Ref No. 12-01R

Issued in: Jan. 2012

Start and run the unit to warm up the engine. Engine must be at

operating temperature before completing Low speed mixture

needle adjustment. Warm up engine for minimum of 3.5

minutes by alternating between Wide Open Throttle (WOT) for

1 minute, then idle for 10 seconds.

■

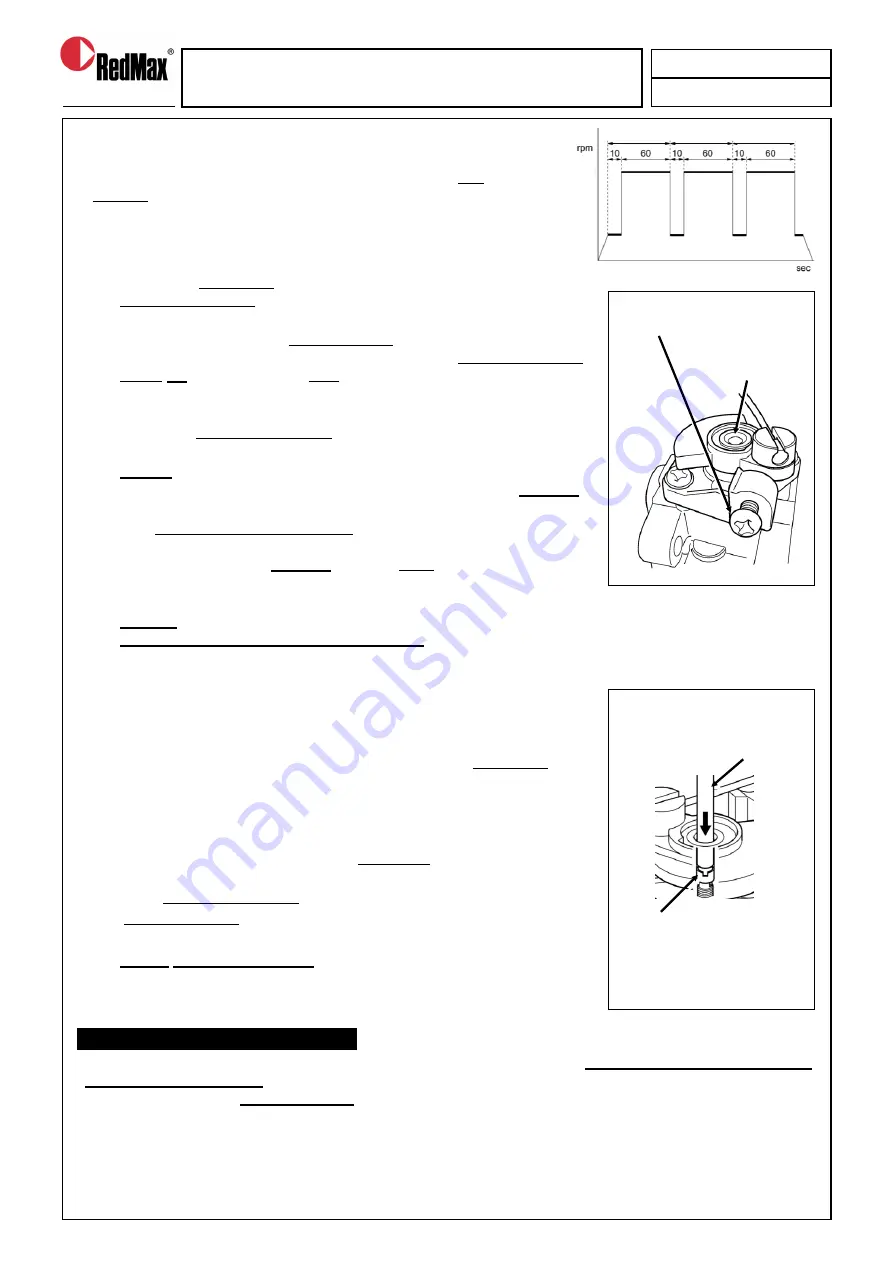

Low Speed Mixture Needle (B) Adjustment

1) Set engine Idle Speed at 3800 +/- 50 RPM by turning Idle speed

throttle valve screw

(A)

. The engine RPM should be stable in the

3800 RPM range.

2)

NOW

adjust Low speed mixture needle

(B)

Clockwise (CW) Leaning

or Counter clockwise (CCW) Richening to reach Maximum engine

speed

AT IDLE

just before lean drop off, where RPM just begins to

drop.

3) If the idle speed at lean drop off is

HIGHER

than 3800 rpm. Adjust

Idle speed throttle valve screw

(A)

Counterclockwise (CCW) down

500 RPM.

4)

Repeat

step 2) and 3) as needed using 500 RPM step reduction,

until maximum lean drop off speed is reached and speed

AT IDLE

is

stable at 3800 +/- 50 RPM.

5) Turn

Low speed mixture needle

(B)

counterclockwise (CCW) in

1/8th turn increments and

Rich Down

the mixture 600 - 800 RPM to

reduce engine speed

AT IDLE

, down to 3000 RPM.

NOTE: Engine speed must be allowed to stabilize a minimum of

20 seconds after each 1/8th of a turn adjustment of Low speed

mixture needle to assure accurate tachometer readings.

Verifying Engine RPM Using Tachometer

■

Checking Maximum RPM

1) Accelerate engine to Wide Open Throttle (WOT).

2) Check the acceleration state of the engine speed, and make sure

that

MINIMUM

engine speed at

WOT

should be at 7500 RPM

3) After checking WOT RPM,

stop

the engine. To comply with the

Emission regulations, insert new limiter cap in the Low speed

mixture needle hole. Press new limiter cap deep into Low speed

mixture needle hole to prevent tampering.

4) Re-Start engine and verify engine Idle speed range from 2800 to

3200 RPM.

5) Verify Wide Open Throttle (WOT) engine speed range should be at

7500-8500 RPM

and the engine should idle and accelerate smoothly.

NOTE: If problem persists, check carburetor for dirt, varnish,

gum, moisture and corrosion contamination.

ATTENTION !!! IMPORTANT !!!

Carburetor adjustments with caps removed must be conducted by Authorized Emission Certified

Servicing Dealers ONLY. The dealer must supply the unit to the customer in the original

configuration, using

manufacturer’s carburetor adjustment procedure, which includes having the

limiter caps in place before the unit is put into service . Knowingly removing or rendering

inoperative a device, element, or design installed on or in a non-road engine which is in

compliance with E.P.A. or C.A.R.B. regulations is classified as TAMPERING.

TAMPERING is a violation of FEDERAL LAW, resulting in significant civil penalties (fines) of up to

$25,000 for each violation.

Low-Speed

Needle (B)

Idle speed

Throttle Valve Screw (A)

Idling

Full

Throttle

1st Time

2nd Time 3rd Time

New

Limiter Cap

Limiter Cap Tool