! - 4S+1.3Ghz warning –

VTX and Camera are both filtered. Only camera power is regulated at (12V or 5V).

Power to the VTX pins is not regulated! The flight battery voltage will be applied. Most 5.8 Ghz video

transmitters have a built in regulator with a wide range to easily accept 3S – 4S standard. Most 1.3 Ghz

video transmitters do not have built in regulators and will need a 12V mini regulator in place on the video

out pins if using a 4S flight pack. A

product like this

can be wired in before the VTX power connections.

! – Solder Bridge Selection -

There are two solder bridges on the Strider RROSD. One for battery regulator

choice (3s or 4s) and one for camera regulated voltage (12v or 5v). Each bridge has 3 pads. Do not bridge all

3 pads at once, which could damage the RROSD if powered up! The Strider will be pre-bridged for you. To

switch to the other choice, remove the solder bridge between two pads, and put in a new solder bridge

between the middle and opposite pad.

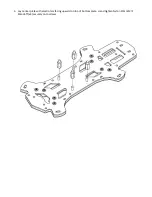

! - Captive nut install -

The captive nuts require significant force to install without a press. One method is to

carefully seat them with a set of pliers. Mask surrounding areas of the PDB appropriately to protect it. Once

the captive nuts are partially seated, lay the board on a solid surface that won’t mar the underside and is

completely flat. Carefully tap the captive nuts in with a hammer till the lip of the nut seats against the top of

the board. Be aware of damaging surrounding components during this step.

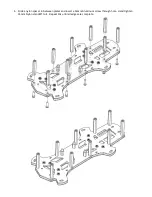

! – Power/Ground wire soldering –

Caution must be taken when soldering wires to the power and ground

pads on the PDB. There are many sensitive components on the RROSD board that a hot soldering iron can

ruin or de-solder if carelessly placed.

Summary of Contents for STRIDER 250

Page 1: ...STRIDER 250...

Page 2: ......

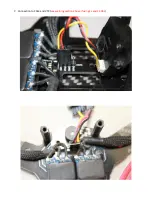

Page 16: ...7 Connection to CAM and VTX see warning section above if using 4s and 1 3Ghz...

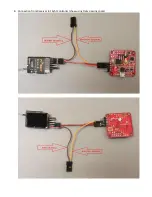

Page 17: ...8 Connection from Receiver to Flight Controller show using Frsky passing cppm...

Page 22: ......

Page 25: ......

Page 26: ...Coming soon...