www.

reefe

.com.au

Ascento Group Australia

©

AI.062020

P: 1800 807 604

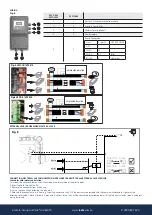

START UP (SINGLE DEVICE)

Be sure that the pump is correctly primed

Connect the device to the electric supply with the magnetothermic switch, FAILURE led light will be ON. Wait for 10 seconds while the device is doing

the autotest. Once it finishes, led light FAILURE is OFF and led light LINE is ON. The LCD screen will show message “SPEEDBOX ” and inmediately the

language display of the configuration mode.

The device is ready for being configured.

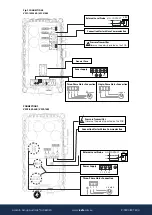

START UP (2 DEVICES ASSEMBLY)

If we wish to mount 2 devices for working in groups, previous point should be exactly followed - the order of connection is irrelevant. During the

configuration process we will be able to choose which device is the

MASTER

.

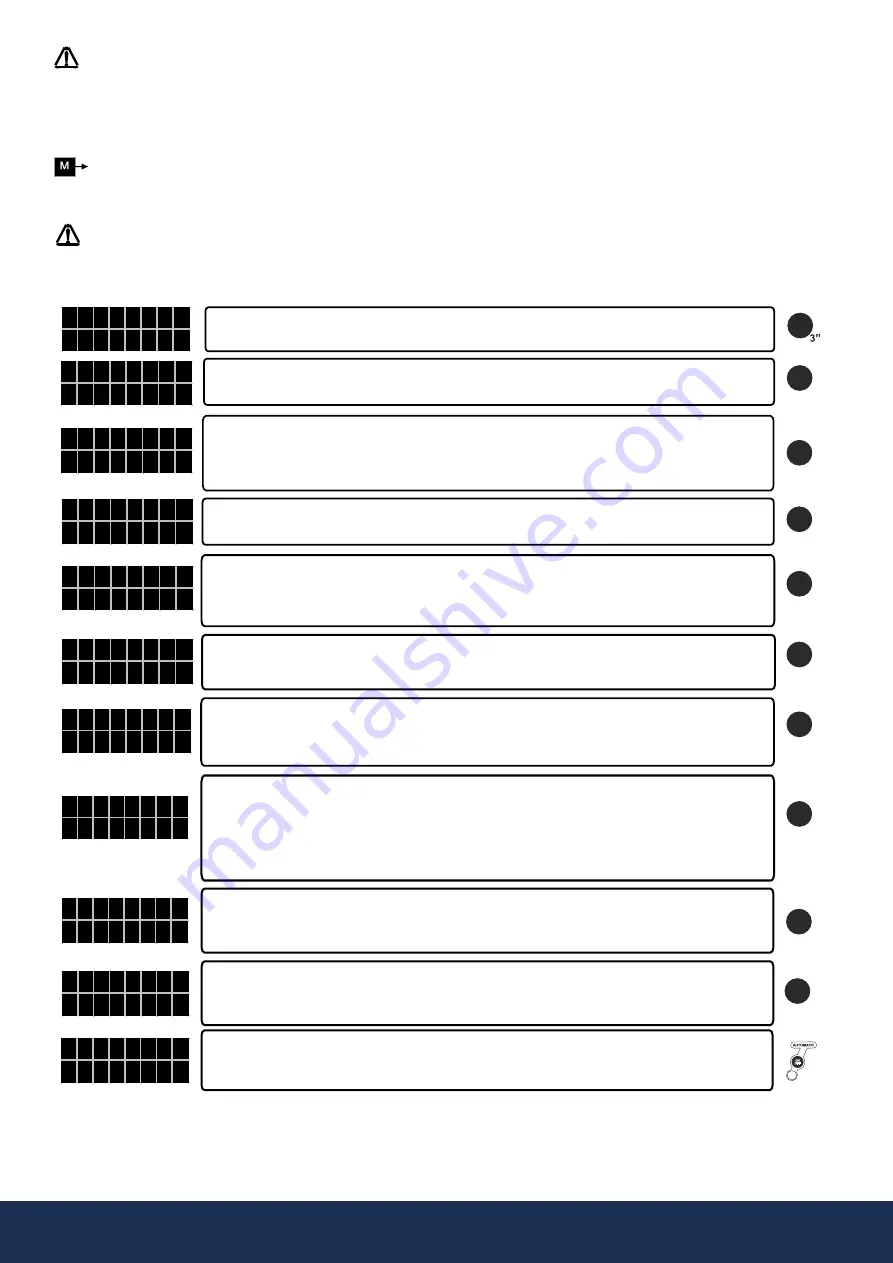

CONFIGURATION

.

Using

we can change the values and press

ENTER

for validation. Whenever we want to quit the configuration sequence press

MENU

. After every

ENTER

it will appears automatically the different screens that constitute the configuration sequence.

MENU

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

P s e t

4 , 0

P b a r

3 , 9

P s e t

4 , 0

P b a r

3 , 9

L A N G U A G E

E N G L I S H

M A X . I N T

1 0

A

R O T A T I O N

0

M I N . F R E Q

1 5

H z

T Y P E

S I N G L E ?

P . S E N S O R

0 - 1 0

b a r

L E V E L ?

N O

OFF

START/

ON

P R E S S U R E

0 3 , 0

b a r

D I F

O N

0 , 5

By mean of keys we can choose lanuages “LANGUAGE ENGLISH”,

“LANGUE FRANCAISE, ”LINQUA ITALIANA” AND IDIOMA ESPANOL”

To start the configuration sequence press

MENU

+

ENTER

during 3”

By mean of keys input the nominal current intensity value in A of the pump enabling the thermal

protection. This value is located over the characteristics plate of the motor. Press

ENTER

for validation.

WARNING: This value is linked with the flow detection system, it is very important to enter the exact

current consumption indicated on the name plate.

ROTATION SENSE.

Using the

START/STOP

pushbutton verify the rotation sense. By mean of keys (0/1)

we can change it. Press

ENTER

for validation.

MINIMUM FREQUENCY.

Using

we can increase the lower frequency value, within 15-48 Hz for 3-phase

pumps and 30-48 Hz for single-phase pumps.

*The minimum frequency value will be used as frequency stop in installations where the automatic detection of the device

do not act due to leaks in the system. See hydraulic installation.

EXTERNAL LEVEL SENSOR.

If the installation does not have level probe

press

ENTER

to validate NO.

If the installation has a level probe, use keys

to change NO by Y.

This will be the system operating pressure. Use keys

for modify the initial value (2 bar)

WARNING! The input pressure must be at least 1 bar lower than the maximum pressure of the pumps.

NOTE:

In case of group assembly, all system operates at the pressure set in the MASTER device, so that the

configuration of set pressure in the slave device is superfluous.

The default value is 0.5 bar. This value of pressure is substracted to the system setpoint, resulting the final

pressure to which the system will set in motion the pump when the hydraulic network has a demand. Use

keys pq to modify the initial value. It is recommended to maintain this value between 0.3 and 0.6 bar.

Example:

- Input pressure: 2 bar

- Differential start: 0.3 bar

- Final start pressure: 2-0.6 = 1.4 bar.

The device is configured by default as

SINGLE.

In case of individual assembly just confirm

SINGLE

by

pushing

ENTER.

In case of group assembly (M-S), we will choose respectively

SLAVE and MASTER

in each

unit pushing

.

The range of lecture of the pressure transmitter installed must be adjusted.

If the range is within 0-10 bar confirm by mean of

ENTER.

If the range is within 0-16 or 0-25 bar change it by mean of

and then confirm with

ENTER

After pressing

ENTER

pushbutton, the system is ready to operate. Press

AUTOMATIC

in order to quit manual

mode.

In case of group assembly press

AUTOMATIC

only in the device set as MASTER.

In case of group assembly, after pressing

AUTOMATIC

in the

MASTER

device, the

AUTOMATIC LED LIGHT

of the

SLAVE

device will start to flash

intermittently, indicating that communication between both devices is ready. If this does not happen verify the connection (Fig 5).